The global wind turbine composites material market has witnessed significant growth in recent years. Wind turbines are essential components of renewable energy systems, and composites materials play a vital role in their construction. Composites offer several advantages, including high strength-to-weight ratio, corrosion resistance, and durability, making them ideal for manufacturing wind turbine components.

Wind turbine composites refer to materials composed of two or more distinct components, typically a matrix and reinforcement, combined to form a composite material. The matrix material provides strength and stiffness, while the reinforcement material enhances mechanical properties. These composites are extensively used in wind turbine blades, nacelles, and other critical components.

Executive Summary

The global wind turbine composites material market is experiencing robust growth, driven by the increasing demand for renewable energy sources and the rising installation of wind turbines worldwide. The market offers lucrative opportunities for industry participants, owing to the advantages offered by composites materials in terms of efficiency, reliability, and sustainability.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

- The wind turbine composites material market is projected to grow at a substantial rate during the forecast period, driven by the increasing focus on renewable energy generation and the need for lightweight and durable turbine components.

- Composite materials, such as carbon fiber reinforced polymers (CFRPs) and glass fiber reinforced polymers (GFRPs), dominate the market due to their excellent mechanical properties and cost-effectiveness.

- The wind energy sector is witnessing significant investments and technological advancements, leading to the development of larger and more efficient wind turbines, further driving the demand for composites materials.

- Stringent government regulations and initiatives promoting renewable energy sources are fueling the adoption of wind turbines, thereby boosting the demand for composites materials.

- Asia Pacific is expected to emerge as a leading market for wind turbine composites materials, primarily due to the rapid industrialization, increasing energy demand, and supportive government policies in countries like China and India.

Market Drivers

The wind turbine composites material market is driven by several key factors:

- Growing Demand for Renewable Energy: With the increasing awareness of climate change and the need to reduce greenhouse gas emissions, there is a rising global demand for renewable energy sources. Wind power is one of the most sustainable and widely adopted sources, driving the demand for wind turbines and, consequently, composites materials.

- Lightweight and High Strength Properties: Composite materials offer superior strength-to-weight ratios compared to traditional materials like steel. This lightweight characteristic makes wind turbine components more efficient and enables higher energy generation.

- Durability and Resistance to Corrosion: Composites materials possess excellent durability and corrosion resistance properties, ensuring the longevity of wind turbine components even in harsh environmental conditions.

- Technological Advancements: Ongoing research and development activities in the field of wind turbine composites materials have led to the development of advanced materials with improved mechanical properties, further driving their adoption in wind turbine manufacturing.

Market Restraints

Despite the promising growth prospects, the wind turbine composites material market faces certain challenges:

- High Initial Costs: The production and installation costs associated with composites materials are relatively higher compared to traditional materials. This can pose a challenge, particularly for smaller wind turbine manufacturers with limited budgets.

- Recycling and Disposal Concerns: While composites offer numerous benefits, the recycling and disposal of these materials pose challenges due to their complex composition. Effective and sustainable recycling methods need to be developed to minimize the environmental impact.

- Dependency on Raw Materials: The availability and cost of raw materials, such as carbon fiber and glass fiber, can impact the overall cost and supply chain of wind turbine composites materials. Fluctuations in raw material prices can affect market growth.

Market Opportunities

The wind turbine composites material market presents several opportunities for industry participants:

- Increasing Wind Power Installations: The global wind power capacity is expected to witness substantial growth in the coming years, driven by government incentives, supportive policies, and the need to reduce carbon emissions. This surge in wind power installations creates a significant demand for wind turbine components, including composites materials.

- Technological Advancements: Ongoing research and development activities are focused on improving the performance and cost-effectiveness of wind turbine composites materials. Innovations in material composition, manufacturing processes, and design techniques can unlock new opportunities for market players.

- Emerging Offshore Wind Sector: The offshore wind energy sector is gaining traction globally due to the abundance of wind resources and the availability of vast open spaces. Offshore wind turbines require advanced materials that can withstand harsh marine environments. Composites materials offer excellent corrosion resistance and durability, making them ideal for offshore applications.

- Increasing Investment in Renewable Energy: Governments and private entities worldwide are investing heavily in renewable energy projects. This investment provides a significant opportunity for wind turbine composites material manufacturers to expand their production capacities and meet the growing demand.

- Collaborations and Partnerships: Collaborations between wind turbine manufacturers, material suppliers, and research institutions can drive innovation and facilitate the development of advanced composites materials. Partnerships can help companies gain a competitive edge and capitalize on emerging opportunities.

Market Dynamics

The wind turbine composites material market is influenced by various dynamics:

- Government Policies and Regulations: Supportive government policies, such as feed-in tariffs and renewable energy targets, play a crucial role in driving the adoption of wind turbines and composites materials. Favorable regulatory frameworks encourage market growth.

- Environmental Concerns: Increasing awareness about environmental issues and the need for sustainable energy sources are driving the demand for wind power. Wind turbine composites materials contribute to the eco-friendly nature of wind turbines, making them an attractive option for renewable energy generation.

- Technological Advancements: Advancements in manufacturing processes, material science, and design techniques contribute to the improved performance and cost-effectiveness of wind turbine composites materials. Continuous technological progress drives market growth and enhances the competitiveness of industry players.

- Economic Factors: Economic factors, such as fluctuations in raw material prices, currency exchange rates, and overall market conditions, can impact the wind turbine composites material market. Market players need to adapt to these factors and implement strategies to mitigate potential risks.

- Competitive Landscape: The market is characterized by intense competition among key players. Companies are investing in research and development, product innovation, and strategic collaborations to gain a competitive advantage and strengthen their market position.

Regional Analysis

The wind turbine composites material market exhibits regional variations:

- North America: The North American market is driven by the presence of established wind energy players, favorable government policies, and significant investments in renewable energy projects. The United States and Canada are key contributors to the regional market growth.

- Europe: Europe is a prominent market for wind turbine composites materials, with countries like Germany, Spain, and Denmark leading the region. The European Union’s renewable energy targets and initiatives support the adoption of wind power and, consequently, composites materials.

- Asia Pacific: The Asia Pacific region is witnessing rapid industrialization and urbanization, resulting in increased energy demand. Countries like China and India are investing heavily in wind power projects, creating significant growth opportunities for wind turbine composites material manufacturers.

- Latin America: Latin American countries, including Brazil and Mexico, are investing in wind power generation to diversify their energy mix and reduce dependence on fossil fuels. This presents a favorable market landscape for wind turbine composites materials.

- Middle East and Africa: The Middle East and Africa region, particularly countries like Saudi Arabia and South Africa, are witnessing a growing interest in wind energy projects. The development of wind farms in these regions creates opportunities for wind turbine composites materials, supported by government initiatives to diversify their energy sources.

- Rest of the World: Other regions, including South America and Oceania, are also experiencing a surge in wind power installations. Countries like Argentina, Australia, and New Zealand are investing in wind energy projects, contributing to the demand for wind turbine composites materials.

Competitive Landscape

Leading Companies in the Global Wind Turbine Composites Material Market:

- Teijin Limited

- Gurit Holding AG

- Toray Industries, Inc.

- Hexcel Corporation

- SGL Carbon SE

- Solvay S.A.

- TPI Composites, Inc.

- Mitsubishi Chemical Corporation

- Kemrock Industries and Exports Ltd.

- Owens Corning

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

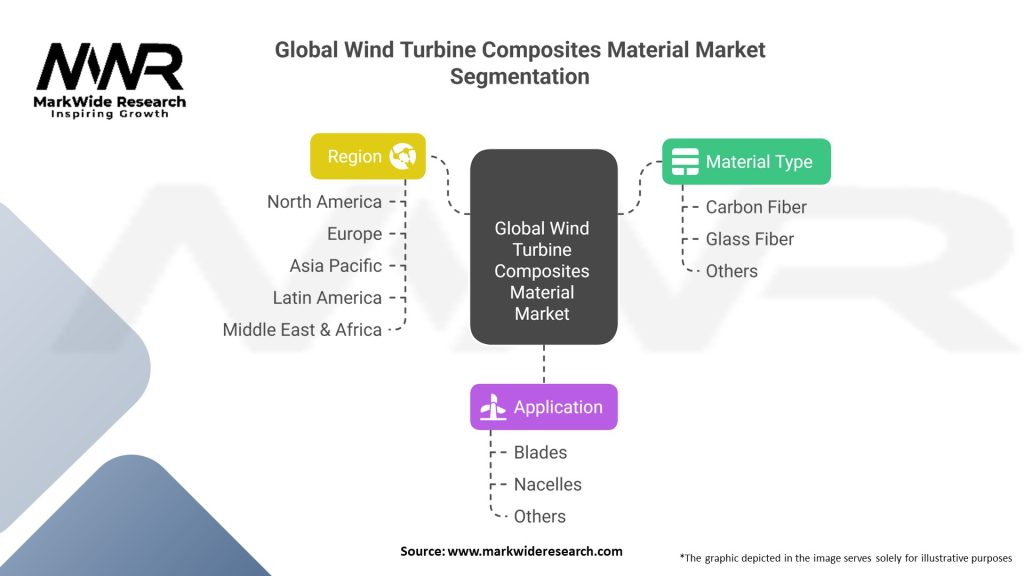

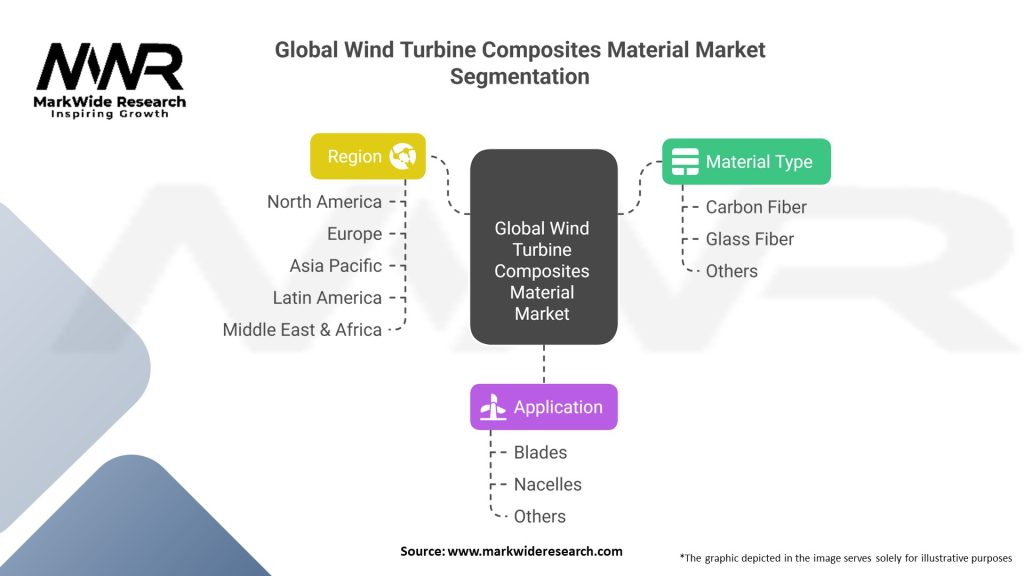

Segmentation

The wind turbine composites material market can be segmented based on:

- Material Type: a. Carbon Fiber Reinforced Polymers (CFRPs) b. Glass Fiber Reinforced Polymers (GFRPs) c. Other Composites Materials (Natural Fibers, Hybrid Composites, etc.)

- Component: a. Blades b. Nacelles c. Hubs d. Towers e. Others

- Application: a. Onshore Wind Turbines b. Offshore Wind Turbines

Segmentation allows for a deeper understanding of market dynamics, customer preferences, and product demand, enabling companies to tailor their strategies and offerings accordingly.

Category-wise Insights

- Blades: Wind turbine blades account for a significant share of the wind turbine composites material market. The trend towards larger and more efficient blades drives the demand for lightweight and durable composites materials.

- Nacelles: Nacelles house the key components of wind turbines, including the generator, gearbox, and control systems. Composites materials offer advantages such as weight reduction, corrosion resistance, and thermal insulation, making them ideal for nacelle construction.

- Towers: Composite materials are increasingly being used in wind turbine towers due to their strength, durability, and ease of manufacturing. Composite towers offer lighter weight, easier transportation, and reduced maintenance requirements.

- Hubs: Hubs connect the blades to the main shaft and play a crucial role in transmitting wind energy. Composites materials provide the necessary strength and stiffness for hubs, ensuring efficient energy transfer.

Key Benefits for Industry Participants and Stakeholders

- Market Growth and Expansion Opportunities: Industry participants can capitalize on the growing demand for wind turbine composites materials by expanding their production capacities, entering new markets, and establishing strategic partnerships.

- Technological Advancements: By investing in research and development, stakeholders can contribute to technological advancements in wind turbine composites materials, leading to improved performance, cost-effectiveness, and sustainability.

- Competitive Advantage: By offering high-quality and innovative composites materials, companies can differentiate themselves from competitors and gain a competitive edge in the market.

- Environmental Impact: The adoption of wind turbine composites materials supports the transition towards clean and sustainable energy sources, contributing to environmental preservation and reducing carbon emissions.

- Cost Efficiency: Wind turbine composites materials offer long-term cost benefits due to their durability, corrosion resistance, and lightweight properties. This can result in reduced maintenance and operational costs for wind turbine owners and operators.

- Enhanced Performance and Reliability: Composites materials contribute to the enhanced performance and reliability of wind turbines. Their high strength-to-weight ratio, resistance to fatigue, and ability to withstand harsh environmental conditions ensure optimal functioning and increased energy generation.

- Regulatory Compliance: Wind turbine composites materials enable industry participants to comply with stringent environmental regulations and sustainability targets set by governments and international organizations.

SWOT Analysis

A SWOT analysis of the wind turbine composites material market provides insights into its strengths, weaknesses, opportunities, and threats:

- Strengths:

- Lightweight and high strength properties of composites materials.

- Durability and corrosion resistance, ensuring longevity of wind turbine components.

- Contribution to clean and sustainable energy generation.

- Weaknesses:

- Higher initial costs compared to traditional materials.

- Challenges in recycling and disposal of composites materials.

- Opportunities:

- Increasing wind power installations globally.

- Technological advancements and innovations in material composition.

- Emerging offshore wind energy sector.

- Growing investment in renewable energy projects.

- Threats:

- Fluctuations in raw material prices.

- Competition from alternative materials and technologies.

- Regulatory and policy uncertainties.

Understanding these factors helps industry participants and stakeholders formulate effective strategies to leverage strengths, overcome weaknesses, seize opportunities, and mitigate threats in the wind turbine composites material market.

Market Key Trends

- Increasing Blade Length: Wind turbine manufacturers are developing longer blades to capture more wind energy and improve overall turbine efficiency. This trend drives the demand for lightweight and strong composites materials to ensure blade performance and reliability.

- Advancements in Material Technology: Ongoing research and development activities focus on developing advanced composites materials with improved mechanical properties, such as higher strength, better fatigue resistance, and enhanced recyclability.

- Integration of Automation and Robotics: Automation and robotics are being utilized in the manufacturing processes of wind turbine composites materials to enhance efficiency, reduce costs, and ensure consistent quality.

- Shift towards Sustainable Manufacturing Practices: Market players are adopting sustainable manufacturing practices, such as using renewable energy sources, optimizing resource consumption, and minimizing waste generation during the production of composites materials.

Covid-19 Impact

The Covid-19 pandemic has had both positive and negative impacts on the wind turbine composites material market:

- Disruptions in the Supply Chain: The pandemic caused disruptions in global supply chains, affecting the availability of raw materials and components required for wind turbine composites materials manufacturing. This led to temporary production halts and delays in project timelines.

- Delayed Wind Power Projects: The pandemic-induced lockdowns and restrictions resulted in delays in the construction and commissioning of wind power projects. This impacted the demand for wind turbine components, including composites materials.

- Resilience of Renewable Energy: Despite the challenges posed by the pandemic, renewable energy, including wind power, has demonstrated resilience and continued to play a vital role in the global energy transition. This resilience has supported the demand for wind turbine composites materials.

- Government Stimulus Packages: Governments worldwide introduced stimulus packages and renewable energy incentives to revive the economy. These initiatives have provided support for wind power projects and indirectly influenced the demand for composites materials.

Key Industry Developments

- Technological Collaboration: Collaborations between wind turbine manufacturers, material suppliers, and research institutions have led to the development of innovative wind turbine composites materials. These collaborations aim to enhance the performance, efficiency, and sustainability of wind turbines.

- Investments in Research and Development: Market players are investing in research and development activities to explore new materials, manufacturing processes, and design techniques for wind turbine composites. This focus on innovation aims to address industry challenges and improve the overall quality and performance of wind turbine components.

- Expansion of Production Capacities: Several companies have expanded their production capacities for wind turbine composites materials to meet the growing demand. This expansion helps cater to the increasing installation of wind turbines and ensures a steady supply of materials to the market.

- Strategic Acquisitions and Partnerships: Companies in the wind turbine composites material market have pursued strategic acquisitions and partnerships to strengthen their market presence and expand their product portfolios. These collaborations enable companies to leverage each other’s expertise and resources for mutual growth.

Analyst Suggestions

- Focus on Cost Optimization: Companies should explore ways to optimize costs throughout the value chain, including raw material sourcing, manufacturing processes, and logistics. Cost optimization can help enhance competitiveness and make wind turbine composites materials more accessible to a broader range of customers.

- Embrace Sustainability: Sustainability is becoming increasingly important in the wind energy sector. Companies should strive to develop sustainable manufacturing practices, improve the recyclability of composites materials, and reduce the environmental impact of wind turbine components.

- Continuous Research and Development: Investing in research and development is crucial for staying at the forefront of technological advancements in wind turbine composites materials. Companies should allocate resources to innovation, explore new materials, and improve the performance and efficiency of wind turbine components.

- Strengthen Customer Relationships: Building strong relationships with wind turbine manufacturers and other industry stakeholders is essential. Understanding customer requirements, providing tailored solutions, and offering excellent customer support can help establish long-term partnerships and gain a competitive advantage.

Future Outlook

The future outlook for the wind turbine composites material market is promising:

- Growing Wind Power Capacity: The increasing global focus on renewable energy sources, along with supportive government policies, will drive the demand for wind turbines. This, in turn, will propel the growth of the wind turbine composites material market.

- Technological Advancements: Ongoing research and development efforts will lead to the development of advanced composites materials with improved properties, such as higher strength, enhanced recyclability, and reduced costs. These advancements will further strengthen the market’s growth potential.

- Offshore Wind Energy Expansion: The offshore wind energy sector is expected to witness significant growth, driven by abundant wind resources and favorable government policies. This expansion will create opportunities for wind turbine composites materials, specifically designed to withstand offshore environments.

- Environmental Sustainability Initiatives: The increasing focus on environmental sustainability and the urgency to combat climate change will drive the adoption of wind power and composites materials. Governments, organizations, and consumers are increasingly prioritizing clean and renewable energy sources.

- Market Consolidation: The wind turbine composites material market will likely witness increased consolidation as companies aim to strengthen their market positions through strategic acquisitions, partnerships, and collaborations. This consolidation will drive innovation, enhance capabilities, and provide comprehensive solutions to customers.

Conclusion

The global wind turbine composites material market is poised for significant growth as renewable energy becomes increasingly important in the global energy landscape. Composites materials offer numerous advantages, including lightweight properties, durability, and corrosion resistance, making them essential for manufacturing wind turbine components.

While challenges exist, such as initial costs and recycling concerns, the market presents immense opportunities for industry participants. Technological advancements, increasing wind power installations, and emerging offshore wind projects create a favorable environment for the growth of the wind turbine composites material market.

Global Wind Turbine Composites Material Market:

| Segmentation |

Details |

| Material Type |

Carbon Fiber, Glass Fiber, Others |

| Application |

Blades, Nacelles, Others |

| Region |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Global Wind Turbine Composites Material Market:

- Teijin Limited

- Gurit Holding AG

- Toray Industries, Inc.

- Hexcel Corporation

- SGL Carbon SE

- Solvay S.A.

- TPI Composites, Inc.

- Mitsubishi Chemical Corporation

- Kemrock Industries and Exports Ltd.

- Owens Corning

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA