444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The global automotive torque vectoring market has been experiencing significant growth in recent years. Torque vectoring is a technology that enables optimal power distribution between the wheels of a vehicle, thereby enhancing its overall performance and stability. It helps improve handling, cornering, and traction, providing a safer and more enjoyable driving experience.

Automotive torque vectoring refers to the ability of a vehicle’s drivetrain system to distribute power between individual wheels or axles to optimize performance and control. It utilizes various mechanisms, such as differential braking, limited-slip differentials, and electronic control systems, to deliver the right amount of torque to each wheel based on driving conditions.

Executive Summary

The global automotive torque vectoring market is witnessing robust growth due to increasing demand for enhanced vehicle performance and safety. Manufacturers are focusing on developing advanced torque vectoring systems to cater to the evolving consumer preferences and stringent regulations. The market is expected to witness substantial expansion in the coming years, driven by technological advancements, rising adoption of electric vehicles, and growing consumer awareness regarding vehicle dynamics.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The global automotive torque vectoring market is characterized by intense competition, technological advancements, and evolving consumer preferences. Key market dynamics include:

Regional Analysis

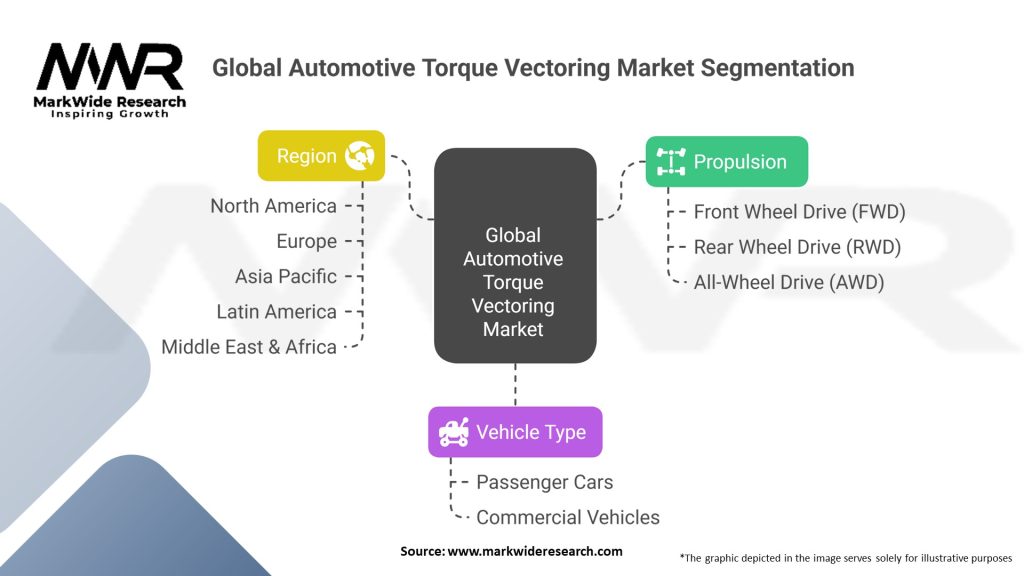

The global automotive torque vectoring market is segmented into several regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

North America: The North American market has witnessed significant growth in the automotive torque vectoring sector, primarily driven by the presence of established automotive manufacturers, high consumer awareness, and the demand for high-performance vehicles. The region’s emphasis on safety regulations and technological advancements further supports the adoption of torque vectoring systems.

Europe: Europe is a prominent market for automotive torque vectoring, owing to the strong presence of luxury and high-performance vehicle manufacturers. Stringent safety regulations, increasing demand for electric vehicles, and advancements in automotive technology are fueling the market growth in this region.

Asia Pacific: The Asia Pacific region is experiencing rapid growth in the automotive torque vectoring market due to the expanding automotive industry, rising disposable incomes, and the increasing demand for premium and performance vehicles. Countries like China, Japan, and South Korea are key contributors to market growth in this region.

Latin America, Middle East, and Africa: These regions are witnessing a steady increase in automotive torque vectoring adoption. The market growth is attributed to the rising focus on vehicle safety, improving economic conditions, and the increasing demand for advanced technology in the automotive sector.

Competitive Landscape

Leading Companies in the Global Automotive Torque Vectoring Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The automotive torque vectoring market can be segmented based on the type of torque vectoring system, vehicle type, and region.

By Type of Torque Vectoring System:

By Vehicle Type:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The global automotive torque vectoring market, like the entire automotive industry, faced significant challenges due to the Covid-19 pandemic. The pandemic disrupted global supply chains, leading to production slowdowns and temporary shutdowns of manufacturing facilities. Consumer demand for vehicles also plummeted as economic uncertainties and lockdown measures were implemented worldwide.

However, the market showed resilience and began to recover as the industry adapted to the new normal. Automakers implemented stringent health and safety protocols to ensure the well-being of their workforce and resumed production gradually. Governments also introduced stimulus packages and incentives to revive the automotive sector, including the promotion of electric and hybrid vehicles.

The pandemic also accelerated certain trends in the automotive industry, which indirectly impacted the torque vectoring market. The shift towards e-commerce and contactless services increased the demand for last-mile delivery vehicles, which could benefit from torque vectoring technology to enhance maneuverability and stability in urban environments.

Moreover, as people sought personal vehicles as a safer mode of transportation, there was a surge in demand for SUVs and crossovers, which are potential candidates for torque vectoring systems. This increased demand for vehicles with better performance and handling characteristics could drive the adoption of torque vectoring technology in the post-pandemic era.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the global automotive torque vectoring market looks promising. The market is expected to witness substantial growth as automakers increasingly integrate torque vectoring systems into their vehicles to meet consumer demands for enhanced performance, safety, and driving experience.

The electric vehicle segment is anticipated to be a key growth driver, with torque vectoring systems playing a vital role in optimizing power distribution in electric powertrains. The ongoing advancements in sensor technology, control algorithms, and vehicle connectivity will further enhance the capabilities of torque vectoring systems, enabling more precise and adaptive torque distribution.

Furthermore, the market is likely to witness collaborations and partnerships between automotive manufacturers and technology providers to accelerate the development and implementation of advanced torque vectoring systems. These collaborations will enable the market players to stay competitive and offer cutting-edge solutions to meet the evolving needs of consumers.

Conclusion

In conclusion, the global automotive torque vectoring market is witnessing steady growth and presents significant opportunities for automakers and technology providers. Torque vectoring technology enhances vehicle performance, safety, and stability by optimizing power distribution between wheels or axles.

The market is driven by factors such as increasing demand for high-performance vehicles, stringent safety regulations, advancements in electric vehicles, and growing consumer awareness about vehicle dynamics. However, challenges such as high implementation costs, complexity in integration, and limited consumer awareness need to be addressed for wider market adoption.

The market offers opportunities in electric vehicles, autonomous and semi-autonomous vehicles, and emerging markets with a growing automotive sector. Strategic collaborations, technological advancements, and a focus on product development and innovation are key trends in the market.

What is Automotive Torque Vectoring?

Automotive Torque Vectoring refers to the technology that allows for the distribution of torque to individual wheels of a vehicle, enhancing traction, stability, and handling. This system is particularly beneficial in performance vehicles and all-wheel-drive systems, improving overall driving dynamics.

What are the key players in the Global Automotive Torque Vectoring Market?

Key players in the Global Automotive Torque Vectoring Market include companies like Bosch, ZF Friedrichshafen, and GKN Automotive. These companies are known for their innovative technologies and contributions to enhancing vehicle performance and safety, among others.

What are the main drivers of growth in the Global Automotive Torque Vectoring Market?

The main drivers of growth in the Global Automotive Torque Vectoring Market include the increasing demand for enhanced vehicle performance, the rise in all-wheel-drive vehicle adoption, and advancements in automotive technology. Additionally, consumer preferences for improved safety features are also contributing to market expansion.

What challenges does the Global Automotive Torque Vectoring Market face?

The Global Automotive Torque Vectoring Market faces challenges such as high development costs and the complexity of integrating torque vectoring systems into existing vehicle architectures. Additionally, the need for continuous innovation to meet consumer expectations can strain resources for manufacturers.

What opportunities exist in the Global Automotive Torque Vectoring Market?

Opportunities in the Global Automotive Torque Vectoring Market include the growing trend towards electric and hybrid vehicles, which can benefit from torque vectoring for improved efficiency. Furthermore, advancements in artificial intelligence and machine learning present new avenues for enhancing torque distribution systems.

What trends are shaping the Global Automotive Torque Vectoring Market?

Trends shaping the Global Automotive Torque Vectoring Market include the increasing integration of advanced driver-assistance systems (ADAS) and the shift towards autonomous vehicles. Additionally, the focus on sustainability is driving innovations in torque vectoring technologies to improve energy efficiency.

Global Automotive Torque Vectoring Market:

| Segmentation | Details |

|---|---|

| Propulsion | Front Wheel Drive (FWD), Rear Wheel Drive (RWD), All-Wheel Drive (AWD) |

| Vehicle Type | Passenger Cars, Commercial Vehicles |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Global Automotive Torque Vectoring Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at