444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The tank level monitoring system market is witnessing significant growth due to the increasing demand for efficient and accurate monitoring solutions across various industries. Tank level monitoring systems are used to measure and manage the fluid levels in tanks, providing real-time data and ensuring optimal utilization of resources. These systems play a crucial role in industries such as oil and gas, chemical, water and wastewater management, and logistics.

Tank level monitoring systems are advanced technology solutions that enable the monitoring and management of fluid levels in tanks. These systems utilize various sensors and instruments to measure the fluid levels accurately and transmit the data to a central monitoring station. The information gathered helps operators to monitor inventory levels, prevent leaks or spills, optimize logistics, and ensure efficient resource management.

The tank level monitoring system market is experiencing steady growth, driven by the need for real-time and accurate monitoring solutions in industries that rely on tanks for storage and transportation. With the advent of IoT (Internet of Things) and wireless communication technologies, tank level monitoring systems have become more sophisticated and efficient, offering enhanced data collection, analysis, and remote monitoring capabilities.

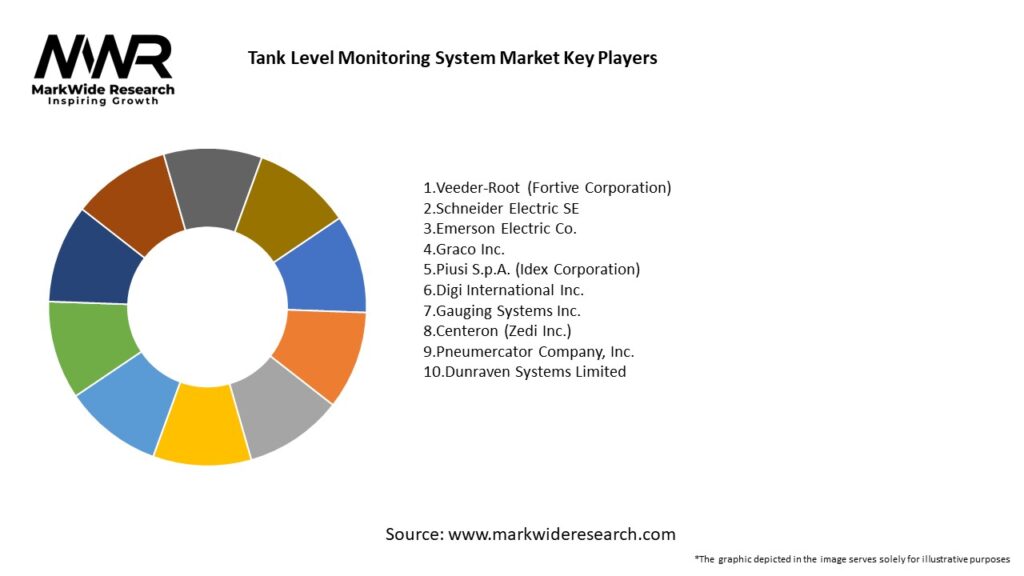

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

The tank level monitoring system market is driven by several dynamic factors. Increasing regulatory compliance requirements, along with the need for accurate inventory management, safety, and cost optimization, are fueling the adoption of these systems. Advancements in sensor technologies, IoT, and cloud computing have further accelerated the market growth. These advancements have enabled seamless integration of tank level monitoring systems with existing infrastructure and improved data sharing for enhanced monitoring and control.

Moreover, the market is witnessing a shift towards wireless and remote monitoring solutions. With the help of wireless connectivity and IoT technology, tank level monitoring systems now provide real-time data access, enabling operators to make proactive decisions and respond quickly to any changes or anomalies. This trend is particularly beneficial for industries with distributed or remote tank installations, as it eliminates the need for manual inspections and enables efficient resource allocation.

The tank level monitoring system market can be analyzed on a regional basis to gain insights into specific market dynamics and trends. The market is experiencing significant growth across regions such as North America, Europe, Asia Pacific, and the Rest of the World.

North America holds a substantial market share due to the presence of well-established industries such as oil and gas, chemicals, and water management. Stringent environmental regulations and safety standards in the region are driving the demand for tank level monitoring systems. Additionally, the focus on optimizing logistics and improving operational efficiency further contributes to the market growth in this region.

Europe is also a prominent market for tank level monitoring systems, primarily driven by the need for compliance with environmental regulations and increasing emphasis on sustainable resource management. The region’s strong manufacturing base and industrial infrastructure support the adoption of advanced monitoring solutions.

The Asia Pacific region is witnessing significant growth potential due to rapid industrialization, urbanization, and infrastructure development. Increasing investments in industries such as oil and gas, chemicals, and water management are driving the demand for tank level monitoring systems. Moreover, the region’s growing focus on environmental sustainability and energy conservation is expected to boost market growth.

Leading Companies in the Tank Level Monitoring System Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

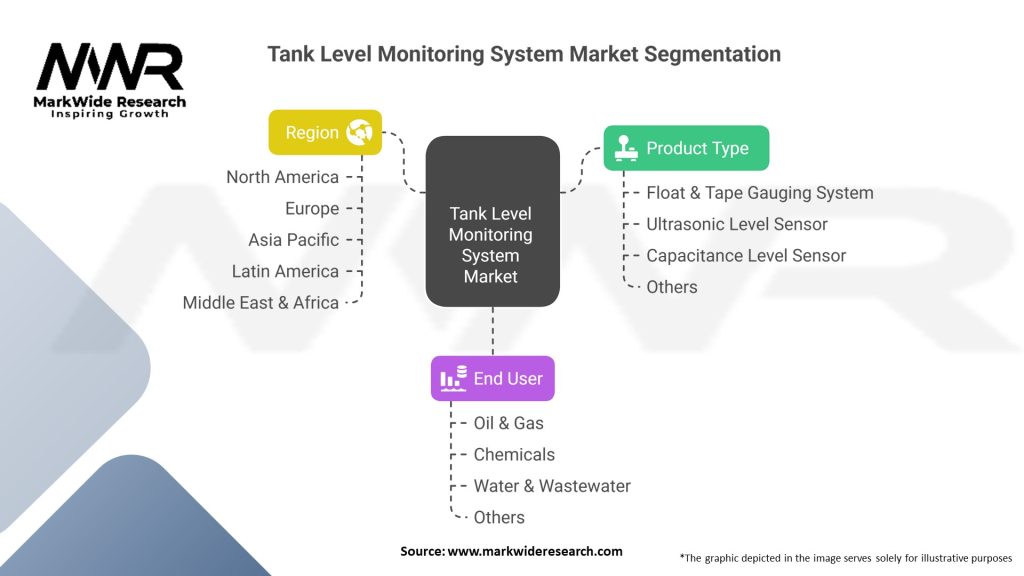

The tank level monitoring system market can be segmented based on technology, component, application, and end-user industry. The technology segment can include ultrasonic, radar, capacitance, and pressure sensors, among others. The component segment comprises hardware, software, and services. Application-wise segmentation can include inventory management, leakage detection, and process optimization. End-user industries encompass oil and gas, chemicals, water and wastewater management, logistics, and others.

The tank level monitoring system market has experienced both challenges and opportunities due to the COVID-19 pandemic. The pandemic has disrupted supply chains, hampered industrial operations, and caused economic uncertainties. As a result, some industries temporarily scaled back their investments in new technologies, including tank level monitoring systems.

However, the pandemic has also highlighted the importance of efficient resource management, supply chain resilience, and remote monitoring capabilities. Industries have realized the need for accurate inventory management, preventive maintenance, and real-time monitoring to ensure operational continuity. This has led to an increased interest in tank level monitoring systems as companies seek ways to optimize their operations and mitigate risks.

Additionally, the pandemic has accelerated the adoption of digital solutions and remote monitoring technologies. Tank level monitoring systems, with their wireless connectivity and remote access capabilities, have proven to be valuable tools in maintaining operational efficiency and ensuring compliance with safety regulations, even in times of restricted physical access.

The tank level monitoring system market is expected to witness substantial growth in the coming years. The increasing demand for accurate inventory management, compliance with safety regulations, and operational efficiency will drive market expansion. The integration of IoT, advanced analytics, and cloud-based solutions will further enhance the capabilities of tank level monitoring systems.

Emerging economies will present significant growth opportunities as industrialization, infrastructure development, and environmental sustainability initiatives gain momentum. Additionally, the expansion of tank level monitoring systems into new industries such as agriculture, pharmaceuticals, and mining will contribute to market growth.

With ongoing advancements in sensor technologies, wireless connectivity, and data analytics, tank level monitoring systems will become more sophisticated, user-friendly, and integrated with existing infrastructure. The market will continue to witness strategic partnerships, acquisitions, and collaborations among industry players to expand their market presence and offer comprehensive solutions.

In conclusion, the tank level monitoring system market is poised for growth, driven by the need for accurate monitoring, safety compliance, and operational efficiency. The market will witness technological advancements, increased adoption of IoT and cloud-based solutions, and a focus on customization and integration. By staying abreast of industry trends, embracing advanced technologies, and offering comprehensive services, companies can capitalize on the opportunities and drive success in the tank level monitoring system market.

Tank Level Monitoring System Market:

| Segmentation | Details |

|---|---|

| Product Type | Float & Tape Gauging System, Ultrasonic Level Sensor, Capacitance Level Sensor, Others |

| End User | Oil & Gas, Chemicals, Water & Wastewater, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Tank Level Monitoring System Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at