444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Drill chucks are an essential tool for any drilling operation, used to secure a drill bit to a drilling machine. The global drill chuck market has seen significant growth in recent years, with increasing demand from various end-use industries, such as construction, manufacturing, and automotive. In this article, we will explore the market overview, key market insights, drivers, restraints, opportunities, regional analysis, competitive landscape, segmentation, category-wise insights, key benefits for industry participants and stakeholders, SWOT analysis, key industry developments, analyst suggestions, future outlook, and conclusion of the drill chuck market.

Meaning of Drill Chuck

A drill chuck is a device that is used to hold a drill bit in place. It is used to secure a drill bit to a drilling machine and is an essential tool for any drilling operation. Drill chucks come in different sizes and types, depending on the drilling machine and the size of the drill bit. They are designed to grip the drill bit firmly and prevent it from slipping during drilling.

Executive Summary

The global drill chuck market is expected to grow significantly in the coming years, driven by the increasing demand from various end-use industries, such as construction, manufacturing, and automotive. The market is highly competitive, with a large number of players operating in the market. Key players in the market are focusing on product innovation and development to gain a competitive edge.

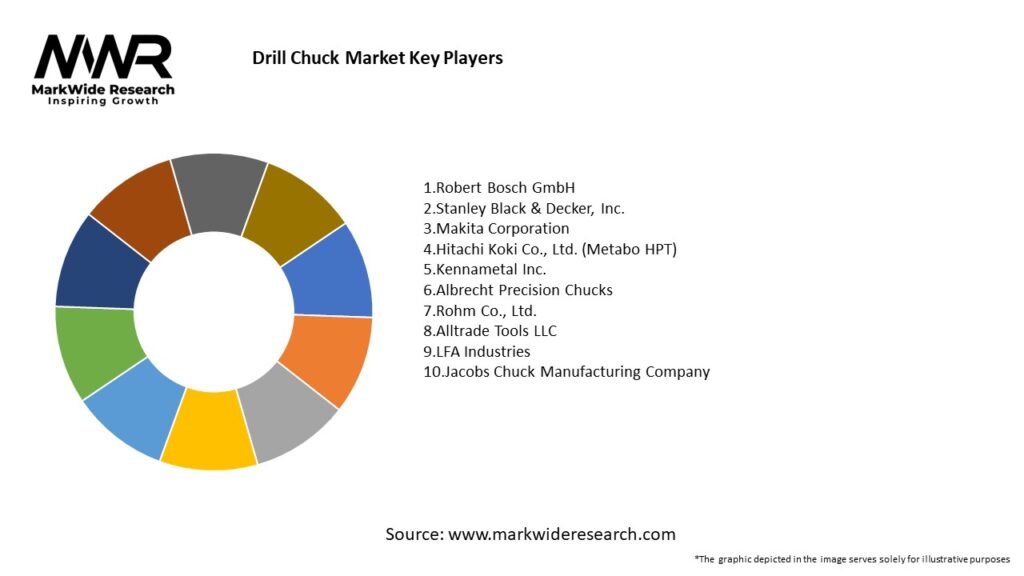

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Technological Advancements: Innovations in drill chuck designs, including keyless and self-tightening models, are enhancing user convenience, improving efficiency, and reducing maintenance needs.

Industry Applications: The demand for drill chucks is growing across various industries, including manufacturing, automotive, aerospace, and construction, where high-precision drilling operations are required.

Emerging Economies: Industrialization and infrastructure development in emerging economies, such as China and India, are driving the demand for drilling equipment and components, including drill chucks.

Customization Demand: With the rise in specialized manufacturing processes, the need for customized drill chucks for specific applications is increasing, providing opportunities for manufacturers to cater to niche markets.

Market Drivers

Several factors are driving the growth of the Drill Chuck Market:

Increasing Industrialization: The rapid growth of industrial sectors, especially in emerging economies, is creating a higher demand for drilling equipment and tools, including drill chucks, which are vital for various manufacturing processes.

Technological Innovation: Advancements in drill chuck technologies, such as the development of keyless and self-tightening chucks, are making drilling operations more efficient, reducing downtime, and improving user convenience.

Demand for Precision: As industries focus on improving the precision and quality of their products, the demand for high-performance drill chucks that can handle intricate drilling operations and minimize error is rising.

Automation in Manufacturing: The increased automation in manufacturing, particularly in industries like automotive and aerospace, is boosting the demand for high-quality drill chucks that can perform efficiently in automated production lines.

Focus on Cost Efficiency: Drill chucks that reduce tool change time, improve productivity, and minimize wear and tear are in high demand, as they help companies reduce operational costs and improve output.

Market Restraints

While the Drill Chuck Market presents strong growth potential, there are certain challenges:

High Initial Cost: The upfront cost of high-performance drill chucks, particularly those with advanced features such as keyless designs or self-tightening mechanisms, can be high, which may deter small businesses and startups from adopting these solutions.

Compatibility Issues: Drill chucks may not always be compatible with all types of drill bits or machines, leading to challenges in adopting specific chuck types across different manufacturing setups.

Maintenance and Repair Costs: While drill chucks are designed for durability, improper maintenance and handling can lead to wear and tear, requiring repair or replacement, which can increase the operational cost for companies.

Competition from Other Tools: Drill chucks face competition from other types of fasteners or tool-holding devices, such as collet chucks and quick-change chucks, which may be preferred in certain applications for their specialized features.

Market Opportunities

The Drill Chuck Market presents several opportunities for growth:

Smart and Automated Drill Chucks: As industries move toward automation and smart manufacturing, there is a growing opportunity for the development of smart drill chucks that offer advanced features such as sensor integration for real-time monitoring and predictive maintenance.

Expansion in Emerging Markets: The industrialization of emerging economies, particularly in Asia-Pacific and Latin America, is creating significant demand for advanced drilling tools, providing growth opportunities for drill chuck manufacturers.

Customization and Specialized Applications: With the growing need for precision in manufacturing, drill chuck manufacturers can tap into niche markets by offering customized solutions for specialized drilling operations, such as those required in aerospace and medical device manufacturing.

Growth in Electric and Hybrid Vehicles: The rise of electric and hybrid vehicle manufacturing, which requires specialized components and precision drilling, is driving the need for high-performance drill chucks in the automotive industry.

Market Dynamics

The Drill Chuck Market is influenced by several dynamics:

Technological Advancements: Continuous innovations in drill chuck design and functionality are enhancing their performance. Features such as keyless designs, self-tightening mechanisms, and ergonomic features are driving consumer demand.

Global Supply Chain: The global supply chain for drill chucks is highly interconnected, with manufacturers sourcing materials from various regions to keep up with demand. Raw material costs, logistics, and geopolitical factors can impact production and pricing.

Industry Demand: The demand for drill chucks is directly tied to the growth of industries that rely on drilling, including manufacturing, automotive, construction, and aerospace. The more these sectors expand, the higher the demand for high-quality drill chucks.

Regulatory Influence: Regulatory standards in industries like aerospace and automotive often require the use of high-precision drilling tools, which can drive demand for high-performance drill chucks that meet these strict standards.

Regional Analysis

The Drill Chuck Market is seeing varying growth trends across different regions:

North America: The North American market is one of the largest consumers of drill chucks, driven by the advanced manufacturing sector, the presence of major automotive and aerospace companies, and increasing demand for precision tools.

Europe: Europe is a significant market, particularly in countries like Germany, the U.K., and France, where automotive, aerospace, and industrial manufacturing are major industries. The demand for precision drilling tools in these sectors is a key growth driver.

Asia-Pacific: Asia-Pacific, led by China and India, is experiencing rapid industrialization, making it one of the fastest-growing markets for drill chucks. The growing automotive, construction, and electronics manufacturing sectors are key drivers of this growth.

Latin America: Latin America is seeing steady growth in the drill chuck market, driven by the expansion of infrastructure projects and the automotive industry, particularly in countries like Brazil and Mexico.

Middle East & Africa: The Middle East and Africa are emerging markets for drill chucks, with rising investments in infrastructure and manufacturing sectors, particularly in countries like Saudi Arabia and the UAE.

Competitive Landscape

Leading Companies in the Drill Chuck Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

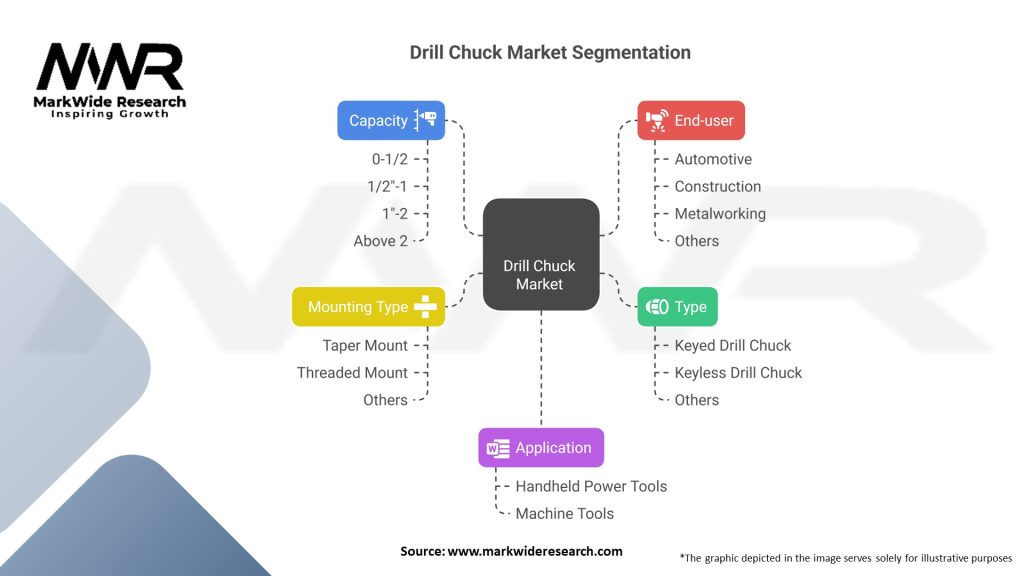

Segmentation

The Drill Chuck Market can be segmented based on various factors:

Type: Keyless Drill Chucks, Self-tightening Drill Chucks, Manual Drill Chucks, Hydraulic Drill Chucks.

End-Use Industry: Manufacturing, Automotive, Aerospace, Construction, Metalworking, Electronics, Others.

Material: Steel, Aluminum, Others.

Category-wise Insights

Keyless Drill Chucks: Keyless drill chucks are in high demand due to their ease of use, as they allow users to tighten and loosen the chuck without the need for additional tools.

Self-tightening Drill Chucks: Self-tightening chucks are popular in industries where high torque is required, such as automotive manufacturing, where precision and reliability are crucial.

Key Benefits for Industry Participants and Stakeholders

Enhanced Efficiency: Drill chucks reduce downtime and improve operational efficiency by enabling fast tool changes and precise drilling operations.

Cost Savings: By improving tool retention, reducing operational inefficiencies, and minimizing downtime, drill chucks help reduce long-term operational costs.

Improved Precision: High-quality drill chucks ensure precision in drilling applications, contributing to better product quality and accuracy.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Automation and Smart Manufacturing: The increasing adoption of automation in manufacturing is driving the need for more efficient, reliable drill chucks that can handle high volumes and precision tasks.

Sustainability Focus: With rising environmental concerns, drill chuck manufacturers are focusing on developing eco-friendly materials and processes to align with sustainability goals.

Covid-19 Impact

The Covid-19 pandemic has had a significant impact on the global drill chuck market. The outbreak of the pandemic has led to a slowdown in the manufacturing and construction sectors, which has affected the demand for drill chucks. Additionally, the disruption of the global supply chain and logistics has led to a shortage of raw materials and components, which has affected the production and distribution of drill chucks. However, the increasing demand for electric and cordless drills for home-based projects during the lockdown has boosted the market growth. Additionally, the growing adoption of digital technologies, such as online sales and remote collaboration tools, has helped the manufacturers to maintain their supply chain and meet the demand for drill chucks.

Key Industry Developments

Some of the key industry developments in the global drill chuck market include:

In May 2021, Rohm launched a new drill chuck series, DDF-E, which is designed for use in high-speed drilling machines.

In December 2020, Albrecht launched a new drill chuck, AERO 40, which is designed for use in the aerospace industry.

In November 2020, Jacobs Chuck launched a new drill chuck, JKP 130-A, which is designed for use in milling machines.

Analyst Suggestions

The global drill chuck market is expected to witness significant growth in the coming years, driven by the increasing demand from various end-use industries, such as construction, manufacturing, and automotive. The growing construction industry in emerging economies and the increasing demand for electric and cordless drills are expected to boost the market growth. Key players in the market are focusing on product innovation and development to gain a competitive edge. Additionally, strategic collaborations and partnerships between manufacturers and distributors are expected to drive the market growth in the coming years.

Future Outlook

The global drill chuck market is expected to grow significantly in the coming years, driven by the increasing demand from various end-use industries, such as construction, manufacturing, and automotive. The growing construction industry in emerging economies and the increasing demand for electric and cordless drills are expected to boost the market growth. Additionally, the focus on product innovation and development and strategic collaborations and partnerships between manufacturers and distributors are expected to drive the market growth in the coming years.

Conclusion

The global drill chuck market is a highly competitive market, with a large number of players operating in the market. The increasing demand from various end-use industries, such as construction, manufacturing, and automotive, is expected to drive the market growth in the coming years. The market is expected to witness significant growth, driven by the growing construction industry in emerging economies and the increasing demand for electric and cordless drills. Key players in the market are focusing on product innovation and development to gain a competitive edge. Additionally, strategic collaborations and partnerships between manufacturers and distributors are expected to drive the market growth in the coming years.

Drill Chuck Market

| Segmentation | Details |

|---|---|

| Type | Keyed Drill Chuck, Keyless Drill Chuck, Others |

| Application | Handheld Power Tools, Machine Tools |

| Mounting Type | Taper Mount, Threaded Mount, Others |

| Capacity | 0-1/2″, 1/2″-1″, 1″-2″, Above 2″ |

| End-user | Automotive, Construction, Metalworking, Others |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Drill Chuck Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at