444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The Industry 4.0 market, also known as the Fourth Industrial Revolution, is transforming the manufacturing industry by incorporating advanced technologies such as artificial intelligence (AI), the Internet of Things (IoT), big data analytics, and robotics into the manufacturing process. This integration of technologies is leading to the development of smart factories, where machines and systems communicate with each other to make informed decisions and optimize production processes.

According to a report by MarketsandMarkets, the global Industry 4.0 market is expected to grow from $73.8 billion in 2020 to $156.6 billion by 2026, at a CAGR of 14.4% during the forecast period. The increasing adoption of Industry 4.0 technologies, the need for improved operational efficiency and productivity, and the growing demand for mass customization are some of the factors driving the growth of the Industry 4.0 market.

Industry 4.0 is a term used to describe the fourth industrial revolution that is transforming the manufacturing industry. It represents the integration of advanced technologies such as AI, IoT, big data analytics, and robotics into the manufacturing process. This integration enables the creation of smart factories that can optimize production processes and make informed decisions.

The key components of Industry 4.0 include cyber-physical systems, which are the integration of the physical and virtual world, and the Internet of Things, which connects machines and devices to the internet. Big data analytics is also an important component of Industry 4.0, as it enables the collection and analysis of large amounts of data to make informed decisions.

Executive Summary

The Industry 4.0 market is expected to grow at a CAGR of 14.4% during the forecast period, driven by the increasing adoption of Industry 4.0 technologies, the need for improved operational efficiency and productivity, and the growing demand for mass customization. The integration of advanced technologies such as AI, IoT, big data analytics, and robotics into the manufacturing process is transforming the industry, leading to the development of smart factories that can optimize production processes and make informed decisions.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The adoption of Industry 4.0 technologies such as AI, IoT, big data analytics, and robotics is increasing in the manufacturing industry. This is due to the benefits that these technologies offer, such as increased productivity, improved operational efficiency, and reduced costs.

The need for improved operational efficiency and productivity is driving the adoption of Industry 4.0 technologies. Smart factories enable the optimization of production processes and the automation of tasks, leading to increased efficiency and productivity.

The growing demand for mass customization is driving the adoption of Industry 4.0 technologies. Smart factories enable the customization of products on a large scale, while maintaining high levels of efficiency and quality.

Governments around the world are increasingly investing in Industry 4.0 initiatives to improve the competitiveness of their manufacturing sectors. This is driving the adoption of Industry 4.0 technologies and creating new opportunities for industry participants.

Market Restraints

The implementation of Industry 4.0 technologies can be costly, especially for small and medium-sized enterprises (SMEs). This is a major barrier to adoption, as SMEs often have limited financial resources.

The integration of advanced technologies requires a highly skilled workforce. The lack of skilled workers in the manufacturing industry is a major restraint to the adoption of Industry 4.0 technologies.

The integration of advanced technologies into the manufacturing process creates new risks in terms of data privacy and security. The increasing amount of data generated by smart factories raises concerns about the protection of sensitive information.

Market Opportunities

Emerging markets such as China, India, and Brazil present significant opportunities for the Industry 4.0 market. These markets have large manufacturing sectors and are increasingly investing in advanced technologies.

The integration of blockchain technology into the manufacturing process has the potential to improve supply chain transparency and efficiency. This presents new opportunities for the Industry 4.0 market.

The demand for predictive maintenance solutions is increasing in the manufacturing industry. Industry 4.0 technologies enable the collection and analysis of large amounts of data, which can be used to predict equipment failures and optimize maintenance schedules.

Market Dynamics

The Industry 4.0 market is highly dynamic, driven by rapid technological advancements and changing customer demands. The market is characterized by intense competition, with a large number of players offering a wide range of products and services.

Regional Analysis

The Asia-Pacific region is expected to be the fastest-growing market for Industry 4.0 during the forecast period. The region is home to some of the largest manufacturing economies in the world, such as China, Japan, and South Korea. The increasing adoption of advanced technologies in the manufacturing sector is driving the growth of the Industry 4.0 market in the region.

Competitive Landscape

Leading Companies in the Industry 4.0 Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

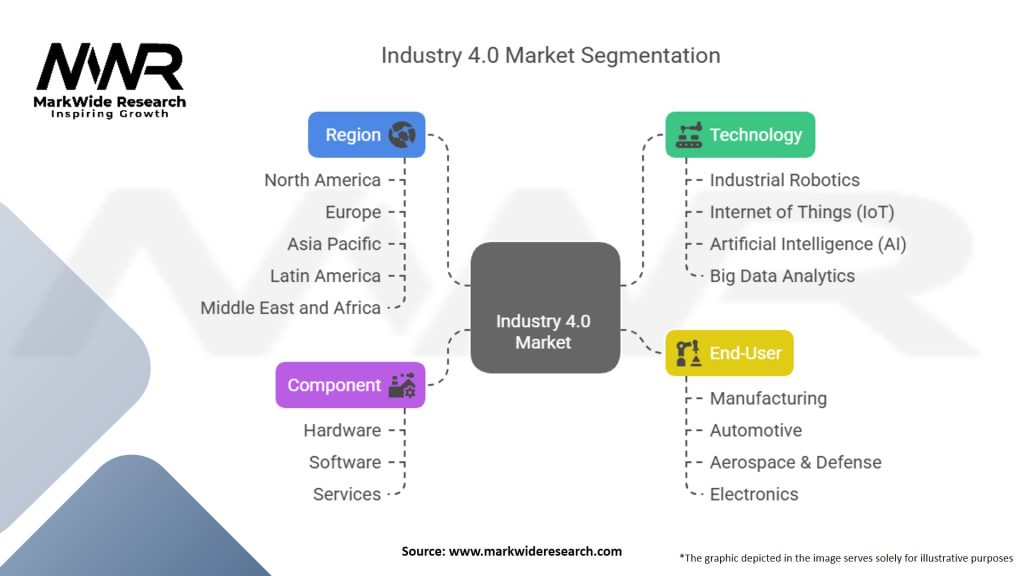

Segmentation

The Industry 4.0 market can be segmented based on technology, application, and region. Based on technology, the market can be segmented into AI, IoT, big data analytics, and robotics. Based on application, the market can be segmented into automotive, aerospace and defense, electronics, food and beverage, and others.

Category-wise Insights

The AI segment is expected to grow at the highest CAGR during the forecast period. The increasing adoption of AI in the manufacturing industry is driving the growth of this segment.

The IoT segment is expected to hold the largest market share during the forecast period. The integration of IoT into the manufacturing process enables the collection and analysis of data from machines and devices, leading to improved efficiency and productivity.

The big data analytics segment is expected to grow at a significant CAGR during the forecast period. The increasing amount of data generated by smart factories is driving the demand for big data analytics solutions.

Key Benefits for Industry Participants and Stakeholders

The integration of advanced technologies into the manufacturing process enables the optimization of production processes, leading to improved efficiency and productivity.

The automation of tasks and optimization of production processes leads to a reduction in costs, as fewer resources are required to produce the same output.

Smart factories enable the customization of products on a large scale, while maintaining high levels of efficiency and quality. This allows manufacturers to meet the increasing demand for personalized products.

The integration of advanced technologies into the manufacturing process enables real-time monitoring and analysis of production processes, leading to improved quality control.

The automation of tasks and use of robotics in the manufacturing process reduces the risk of accidents and injuries, leading to a safer working environment.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

The integration of AI and big data analytics is a key trend in the Industry 4.0 market. This enables the collection and analysis of large amounts of data, leading to improved decision-making and optimization of production processes.

The demand for predictive maintenance solutions is increasing in the manufacturing industry. Industry 4.0 technologies enable the collection and analysis of data, which can be used to predict equipment failures and optimize maintenance schedules.

Covid-19 Impact

The Covid-19 pandemic has had a significant impact on the manufacturing industry, with disruptions to global supply chains and reduced demand for products. However, it has also accelerated the adoption of Industry 4.0 technologies, as manufacturers look to improve efficiency and reduce costs.

The pandemic has highlighted the importance of automation and digitalization in the manufacturing industry, as companies look to reduce their reliance on manual labor and improve their agility and flexibility.

Key Industry Developments

Siemens AG has launched a new platform, “Mindsphere World,” which aims to bring together experts from across the Industry 4.0 ecosystem to drive innovation and collaboration.

General Electric Company has partnered with Apple Inc. to develop a new software platform for the Industrial Internet of Things (IIoT).

Analyst Suggestions

Industry participants should focus on developing cost-effective solutions to overcome the barrier of high implementation costs.

Investing in workforce training and development is essential to address the skill shortage in the manufacturing industry and enable the adoption of advanced technologies.

Future Outlook

The Industry 4.0 market is expected to continue to grow at a significant pace in the coming years, driven by the increasing adoption of advanced technologies and the need for improved efficiency and productivity. The integration of AI, IoT, big data analytics, and robotics into the manufacturing process will continue to transform the industry, leading to the development of smarter and more efficient factories.

Conclusion

The Industry 4.0 market is expected to grow at a significant pace in the coming years, driven by the increasing adoption of advanced technologies, the need for improved efficiency and productivity, and the growing demand for mass customization. However, the implementation of Industry 4.0 technologies can be costly, especially for small and medium-sized enterprises (SMEs), and the lack of skilled workers in the manufacturing industry is a major restraint to the adoption of Industry 4.0 technologies.

Emerging markets such as China, India, and Brazil present significant opportunities for the Industry 4.0 market, and the integration of blockchain technology into the manufacturing process presents new opportunities for industry participants.

What is Industry 4.0?

Industry 4.0 refers to the fourth industrial revolution characterized by the integration of digital technologies, automation, and data exchange in manufacturing processes. It encompasses concepts such as the Internet of Things (IoT), artificial intelligence, and smart factories.

Who are the key players in the Industry 4.0 Market?

Key players in the Industry 4.0 Market include Siemens, General Electric, Bosch, and Rockwell Automation, among others. These companies are leading the way in developing innovative solutions that enhance manufacturing efficiency and connectivity.

What are the main drivers of growth in the Industry 4.0 Market?

The main drivers of growth in the Industry 4.0 Market include the increasing demand for automation, the need for operational efficiency, and the rise of smart manufacturing technologies. Additionally, the growing emphasis on data analytics and real-time monitoring is propelling market expansion.

What challenges does the Industry 4.0 Market face?

The Industry 4.0 Market faces challenges such as cybersecurity risks, high implementation costs, and the need for skilled workforce. These factors can hinder the adoption of advanced technologies in manufacturing environments.

What opportunities exist in the Industry 4.0 Market?

Opportunities in the Industry 4.0 Market include the development of new technologies like AI and machine learning, the expansion of smart supply chains, and the potential for enhanced sustainability practices. Companies can leverage these trends to innovate and improve their operations.

What trends are shaping the Industry 4.0 Market?

Trends shaping the Industry 4.0 Market include the increasing use of IoT devices, the rise of digital twins, and the integration of advanced robotics in manufacturing. These innovations are transforming traditional processes and enabling more efficient production methods.

Industry 4.0 Market

| Segmentation | Details |

|---|---|

| Technology | Industrial Robotics, Internet of Things (IoT), Artificial Intelligence (AI), Big Data Analytics, Others |

| Component | Hardware, Software, Services |

| End-User | Manufacturing, Automotive, Aerospace & Defense, Electronics, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East and Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Industry 4.0 Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at