444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Vapor Phase Soldering (VPS) Machine market is poised for significant growth, driven by its remarkable efficiency and precision in soldering electronic components. VPS technology has rapidly gained traction as a reliable solution in various industries, including electronics manufacturing, automotive, aerospace, and medical devices. This market overview delves into the core aspects of VPS machines, shedding light on their meaning, key insights, drivers, restraints, opportunities, and more.

Meaning

Vapor Phase Soldering (VPS) is an advanced soldering technique that utilizes vaporized solder to create a controlled soldering environment. This technology ensures soldering with unparalleled precision, as the phase change of the solder vapor releases energy, providing a consistent temperature profile across the components. VPS machines offer a superior soldering process, even for complex assemblies and miniaturized components, making them indispensable in modern electronics manufacturing.

Executive Summary

The Vapor Phase Soldering (VPS) Machine market is undergoing a transformative phase, witnessing increased adoption due to its ability to address the limitations of traditional soldering methods. VPS technology’s exceptional thermal uniformity and reduced thermal stress result in impeccable solder joints. This executive summary provides a glimpse into the key market insights, driving factors, challenges, and future outlook of the VPS Machine market.

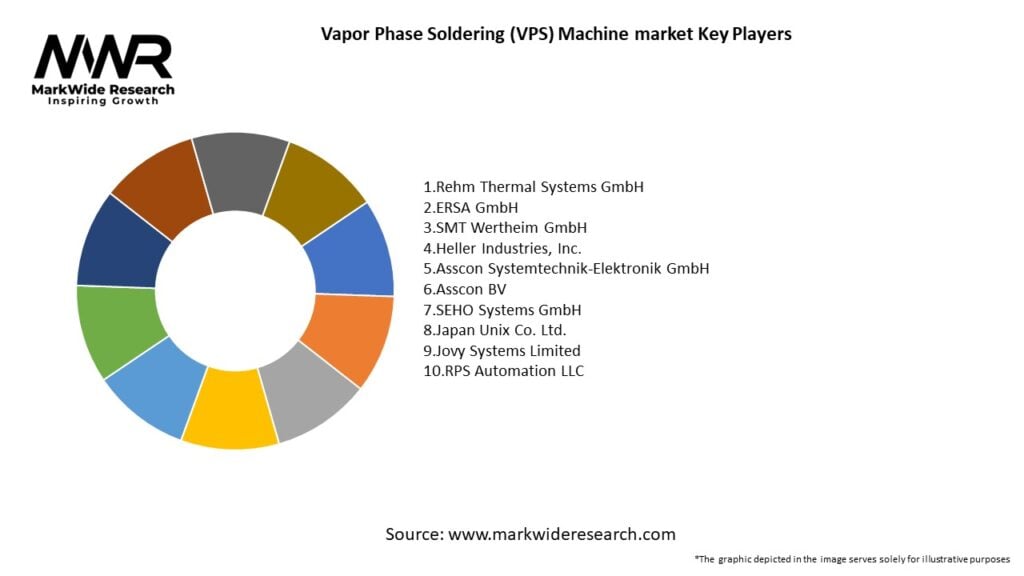

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Several factors are driving the growth of the Vapor Phase Soldering (VPS) Machine market:

Rising Demand for Precision Soldering: The increasing complexity of electronic components and the demand for higher precision in the assembly of printed circuit boards (PCBs) are pushing the adoption of VPS machines in various industries.

Miniaturization of Electronics: As the trend towards miniaturized electronic devices continues, VPS machines offer the precision required to solder smaller components with fine-pitch leads, making them ideal for the miniaturization of consumer electronics, medical devices, and automotive electronics.

Increasing Complexity in Electronics Assembly: Modern electronic assemblies often require fine-pitch components and multi-layer PCBs, which are better handled by VPS machines due to their ability to deliver consistent heat and minimize thermal stress.

Demand for High-Reliability Applications: Industries such as automotive, aerospace, and telecommunications require high-reliability solder joints. VPS machines provide consistent quality, ensuring that solder joints meet the strict standards required for these applications.

Technological Advancements: Advances in VPS technology, including automation, enhanced process controls, and integration with smart manufacturing systems (Industry 4.0), are making VPS machines more efficient and accessible, driving their adoption.

Market Restraints

Despite its growth potential, the Vapor Phase Soldering (VPS) Machine market faces several challenges:

High Initial Investment: VPS machines can be costly, especially for small and medium-sized businesses. The initial investment, along with the cost of maintenance and operation, can be a barrier to adoption, particularly in cost-sensitive industries.

Size and Space Requirements: VPS machines require substantial space for installation and operation, which may be challenging for smaller manufacturing setups with limited space.

Competition from Other Soldering Techniques: VPS faces competition from other soldering methods, such as wave soldering, reflow soldering, and selective soldering, which are often more cost-effective and suitable for large-scale production.

Complexity of Operation: VPS machines are more complex to operate compared to traditional soldering methods. Skilled operators are required to ensure optimal machine performance and achieve the desired soldering results, which can add to labor costs.

Market Opportunities

The Vapor Phase Soldering (VPS) Machine market presents numerous opportunities for growth:

Expansion in Emerging Markets: The increasing adoption of electronics in emerging markets, such as Asia-Pacific, Latin America, and the Middle East, presents significant growth opportunities for VPS machines as these regions expand their manufacturing capabilities.

Automation and Industry 4.0 Integration: The integration of VPS machines with automated manufacturing lines and smart systems can improve production efficiency, reduce downtime, and increase output, presenting opportunities for manufacturers to optimize their processes.

Development of Eco-Friendly Soldering Solutions: With increasing environmental concerns, there is an opportunity for manufacturers to develop more eco-friendly VPS solutions, such as the use of non-toxic fluxes and more energy-efficient machines, to appeal to environmentally conscious companies.

Growth in the Automotive and Aerospace Sectors: The automotive and aerospace industries require high-reliability soldering solutions for critical components. VPS machines can help meet the high standards of these industries, driving demand for precise and durable soldering systems.

Innovation in Additive Manufacturing: As additive manufacturing (3D printing) continues to grow, there is an opportunity to integrate VPS machines into the production of complex, printed electronic components, offering precise soldering for unique geometries and intricate designs.

Market Dynamics

The Vapor Phase Soldering (VPS) Machine market is influenced by several key dynamics:

Technological Advancements in Soldering: Advances in machine automation, improved vapor phase fluxes, and enhanced thermal management systems are enabling VPS machines to deliver more precise, faster, and cost-effective soldering solutions.

Regulatory Compliance: Increasing regulatory requirements in industries such as aerospace, automotive, and medical devices are pushing companies to adopt high-quality soldering solutions that meet safety and reliability standards. VPS machines offer the precision and consistency needed to meet these demands.

Growth in Miniaturized Electronics: As consumer electronics and medical devices become smaller, the need for precise soldering techniques has grown. VPS machines are well-suited for these applications due to their ability to handle fine-pitch components without thermal damage.

Customization and Versatility: VPS machines are becoming increasingly customizable to meet the unique needs of various industries, offering flexibility in terms of soldering parameters, heating profiles, and the use of different types of flux and media.

Regional Analysis

The US Vapor Phase Soldering (VPS) Machine market shows varying trends across different regions:

North America: North America, particularly the US, is a key market for VPS machines, driven by the growing demand for high-precision soldering in industries like electronics, aerospace, and automotive. The presence of major manufacturing hubs and the need for quality control in high-reliability applications are driving market growth.

Europe: Europe is another significant market, where countries like Germany, the UK, and France are witnessing strong demand for VPS machines. The automotive, aerospace, and electronics sectors in Europe are increasingly adopting VPS technology for complex and high-precision applications.

Asia-Pacific: The Asia-Pacific region is expected to experience the highest growth rate in the VPS machine market, driven by rapid advancements in electronics manufacturing, particularly in countries like China, Japan, and South Korea, where demand for high-precision soldering is growing.

Latin America: Latin America is a growing market for VPS machines, with countries like Brazil and Mexico seeing increased adoption due to the expansion of their electronics manufacturing industries.

Middle East & Africa: The Middle East & Africa region is gradually adopting advanced soldering technologies like VPS, particularly in the aerospace and automotive industries, which require high-reliability soldering solutions.

Competitive Landscape

Leading Companies in the Vapor Phase Soldering (VPS) Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Vapor Phase Soldering (VPS) Machine market can be segmented based on the following:

By Type: Manual VPS Machines, Automated VPS Machines.

By End-User Industry: Electronics, Automotive, Aerospace, Medical Devices, Telecommunications, Others.

By Application: PCB Soldering, Component Soldering, Connector Soldering, Others.

By Region: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The Vapor Phase Soldering (VPS) Machine market offers several benefits for stakeholders:

Enhanced Precision: VPS machines provide high precision in soldering, reducing the risk of component damage and ensuring better product performance.

Reduced Thermal Stress: VPS technology offers superior thermal management, minimizing the risk of heat-related damage to sensitive components, which is crucial in high-reliability industries.

Eco-Friendly: VPS machines are more environmentally friendly than other soldering methods, as they produce less airborne dust and minimize the use of harmful chemicals.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had mixed effects on the VPS Machine market. While the initial disruptions in supply chains posed challenges, the increased reliance on electronics, especially in the medical sector, underscored the importance of reliable soldering. The pandemic accelerated the adoption of automation and smart manufacturing, indirectly benefiting the VPS Machine market as manufacturers sought efficient, high-quality soldering solutions.

Key Industry Developments

Recent industry developments include advancements in solder paste formulations optimized for VPS technology. These formulations ensure better solder wetting and joint integrity. Moreover, the integration of machine learning and artificial intelligence in VPS machines is streamlining temperature profiling and process optimization, contributing to more consistent and reliable soldering outcomes.

Analyst Suggestions

Industry analysts suggest that manufacturers keen on staying competitive should explore collaborations with VPS machine providers to tailor solutions to their specific needs. Investing in workforce training to maximize the potential of VPS machines is also recommended. Monitoring regulatory changes and adapting to evolving environmental requirements will be crucial in ensuring long-term market relevance.

Future Outlook

The future of the VPS Machine market appears promising, driven by the relentless pursuit of higher product quality and reliability. As the technology matures, it is likely to become more accessible and cost-effective, enabling broader adoption across industries. The market will witness further integration of data-driven insights and predictive analytics, cementing VPS machines’ position as a cornerstone of modern electronics manufacturing.

Conclusion

In conclusion, the Vapor Phase Soldering (VPS) Machine market is undergoing a transformative journey, redefining soldering standards across industries. The technology’s exceptional precision, thermal uniformity, and compatibility with intricate designs set it apart as a leading soldering solution. While challenges exist, the market’s growth trajectory remains positive, driven by the increasing demand for reliable, high-quality solder joints. As VPS machines continue to evolve, they are poised to play a pivotal role in shaping the future of electronics manufacturing.

Vapor Phase Soldering (VPS) Machine market

| Segmentation Details | Description |

|---|---|

| Product Type | Batch VPS, Inline VPS, Compact VPS, Large VPS |

| Technology | Condensation, Vacuum, Infrared, Convection |

| Application | PCB Assembly, Semiconductor Packaging, LED Manufacturing, Aerospace Components |

| End User | Electronics Manufacturers, OEMs, Contract Manufacturers, Research Labs |

Leading Companies in the Vapor Phase Soldering (VPS) Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at