444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The United States Non-Ferrous Scrap Recycling market plays a pivotal role in the country’s recycling and sustainability efforts. Non-ferrous scrap refers to metal waste that does not contain iron, such as aluminum, copper, lead, zinc, and nickel. Recycling non-ferrous scrap is essential for conserving natural resources, reducing energy consumption, and minimizing environmental impacts. The market is driven by increasing awareness of environmental concerns, stringent regulations promoting recycling practices, and the economic benefits associated with metal recycling. As the United States strives to achieve its sustainability goals, the non-ferrous scrap recycling market is expected to witness significant growth.

Meaning

The United States Non-Ferrous Scrap Recycling market is a specialized sector within the recycling industry, focused on the collection, processing, and reclamation of non-ferrous metals. Non-ferrous metals are valuable resources that can be recycled repeatedly without losing their properties, making recycling an economically and environmentally attractive option. This market contributes to resource conservation, energy savings, and waste reduction, supporting the country’s efforts towards a circular economy and sustainable future.

Executive Summary

The United States Non-Ferrous Scrap Recycling market is a critical component of the recycling industry, dedicated to reclaiming valuable non-ferrous metals from scrap materials. This comprehensive report provides key insights into the market’s drivers, restraints, opportunities, and dynamics, enabling industry participants and stakeholders to make informed decisions.

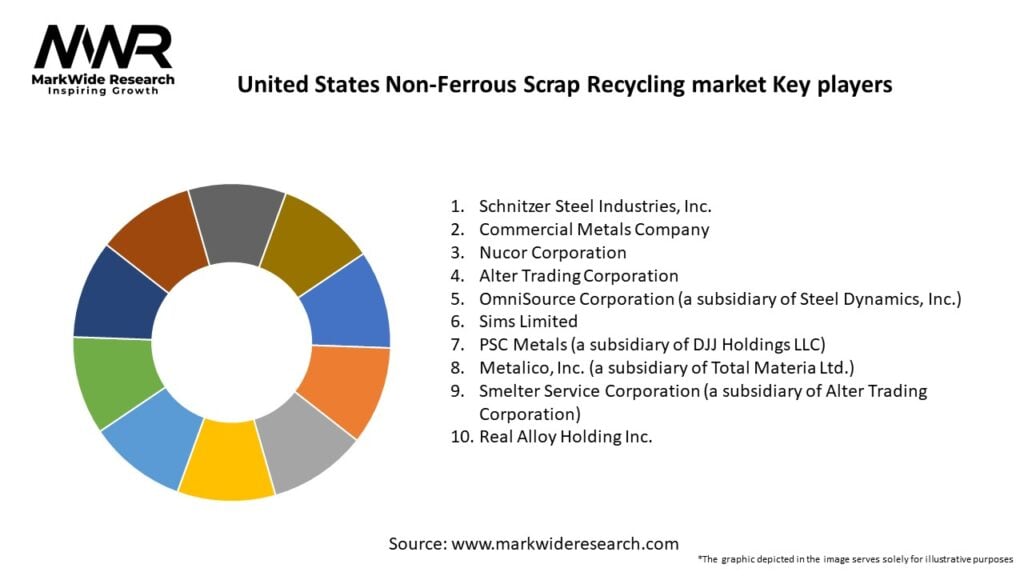

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

The United States Non-Ferrous Scrap Recycling Market is influenced by several critical factors that underscore its importance:

These insights highlight the market’s strategic significance in reducing environmental impact, stabilizing supply chains, and generating economic benefits through efficient resource management.

Market Drivers

Several key factors are driving the growth of the United States Non-Ferrous Scrap Recycling Market:

These drivers collectively contribute to a robust market environment that supports long-term growth and sustainable practices in non-ferrous scrap recycling.

Market Restraints

Despite its promising growth prospects, the United States Non-Ferrous Scrap Recycling Market faces several challenges:

Addressing these restraints will require strategic planning, efficient resource allocation, and proactive regulatory engagement to mitigate risks and ensure steady market growth.

Market Opportunities

The United States Non-Ferrous Scrap Recycling Market presents numerous opportunities for expansion and innovation:

These opportunities, if strategically leveraged, can drive significant growth and enhance the overall competitiveness of the market.

Market Dynamics

The dynamics of the United States Non-Ferrous Scrap Recycling Market are shaped by a complex interplay of supply and demand factors, technological innovation, and regulatory influences:

Supply Side Factors:

Demand Side Factors:

Economic and Regulatory Influences:

Understanding these dynamics is critical for stakeholders to optimize operations, plan strategic investments, and navigate the competitive landscape effectively.

Regional Analysis

Within the United States, the non-ferrous scrap recycling market exhibits regional variations influenced by industrial concentration, regulatory environments, and infrastructure development:

Northeast:

The Northeast region benefits from a high concentration of industrial activities and robust recycling regulations. With strong environmental standards and advanced recycling facilities, this area remains a significant contributor to non-ferrous scrap recovery.

Midwest:

Known for its manufacturing and automotive industries, the Midwest region has a well-established infrastructure for scrap collection and processing. The presence of large-scale recyclers and supportive industrial policies drives growth in this area.

South:

The Southern United States is experiencing rapid industrial expansion, leading to increased scrap generation. Improvements in recycling infrastructure and favorable economic conditions are making this region a growing market for non-ferrous scrap recycling.

West:

In the West, particularly in states with a strong emphasis on sustainability and environmental regulations, the market is driven by high consumer awareness and advanced technological adoption in recycling practices.

Regional differences in regulatory frameworks, industrial activity, and infrastructure investments shape market opportunities and challenges across the country.

Competitive Landscape

Leading Companies in the United States Non-Ferrous Scrap Recycling Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

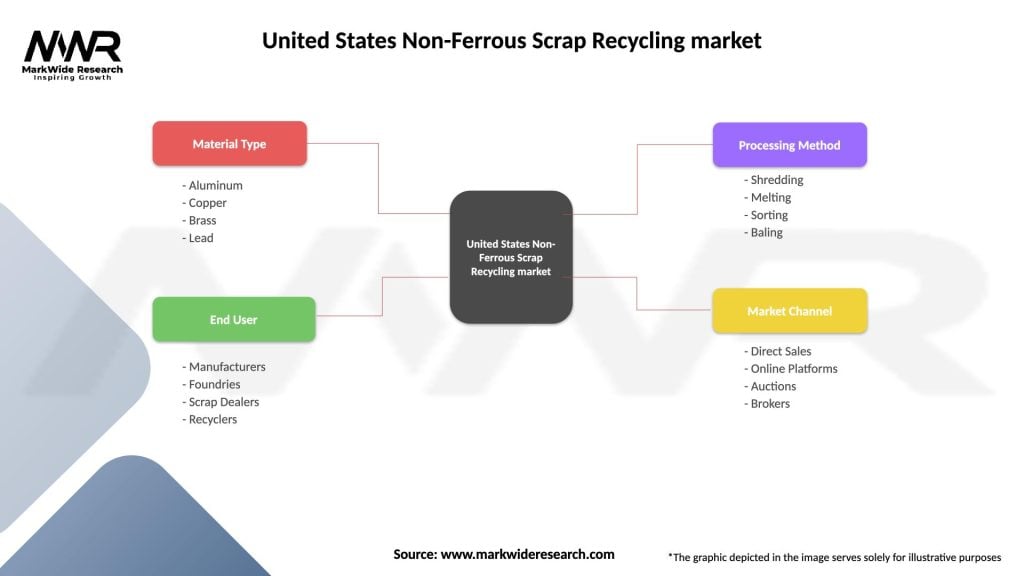

Segmentation

The United States Non-Ferrous Scrap Recycling Market can be segmented based on scrap type, processing technology, end-use industry, and distribution channel:

By Scrap Type:

By Processing Technology:

By End-Use Industry:

By Distribution Channel:

Category-wise Insights

Each segment within the United States Non-Ferrous Scrap Recycling Market presents unique benefits and challenges:

Key Benefits for Industry Participants and Stakeholders

Adopting and investing in non-ferrous scrap recycling offers multiple benefits:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Several key trends are shaping the future of the United States Non-Ferrous Scrap Recycling Market:

Covid-19 Impact

The Covid-19 pandemic has had a notable impact on the United States Non-Ferrous Scrap Recycling Market:

Key Industry Developments

Recent industry developments in the United States Non-Ferrous Scrap Recycling Market are paving the way for future growth:

Analyst Suggestions

Based on current trends and market challenges, industry analysts recommend the following strategies for stakeholders in the United States Non-Ferrous Scrap Recycling Market:

Future Outlook

The future of the United States Non-Ferrous Scrap Recycling Market is highly promising, with continued growth expected as technological innovations, regulatory support, and increasing industrial demand drive market expansion. Key future trends include:

Despite challenges such as price volatility and integration complexities, stakeholders that invest in innovation, sustainability, and strategic market expansion are well-positioned to capitalize on emerging opportunities and drive long-term growth.

Conclusion

The United States Non-Ferrous Scrap Recycling Market is a critical component of the nation’s sustainable industrial ecosystem. By efficiently recovering and processing valuable metals from waste, the market not only reduces environmental impact but also contributes significantly to economic growth and resource efficiency. Driven by technological innovations, stringent environmental regulations, and growing industrial demand, the market is poised for continued expansion. While challenges such as price volatility, regulatory complexities, and high capital investments persist, the opportunities provided by digital transformation, sustainability initiatives, and strategic partnerships outweigh these obstacles. As the United States continues to embrace a circular economy and invest in advanced recycling infrastructure, the non-ferrous scrap recycling market will remain a vital driver of industrial innovation and environmental stewardship.

What is Non-Ferrous Scrap Recycling?

Non-Ferrous Scrap Recycling refers to the process of recovering and processing non-ferrous metals, such as aluminum, copper, and lead, from scrap materials. This recycling is essential for reducing waste and conserving natural resources.

What are the key players in the United States Non-Ferrous Scrap Recycling market?

Key players in the United States Non-Ferrous Scrap Recycling market include companies like Schnitzer Steel Industries, Inc., Commercial Metals Company, and OmniSource Corporation, among others.

What are the main drivers of the United States Non-Ferrous Scrap Recycling market?

The main drivers of the United States Non-Ferrous Scrap Recycling market include the increasing demand for recycled metals in manufacturing, the rising awareness of environmental sustainability, and government regulations promoting recycling practices.

What challenges does the United States Non-Ferrous Scrap Recycling market face?

Challenges in the United States Non-Ferrous Scrap Recycling market include fluctuating metal prices, contamination of scrap materials, and competition from virgin metal production, which can impact recycling profitability.

What opportunities exist in the United States Non-Ferrous Scrap Recycling market?

Opportunities in the United States Non-Ferrous Scrap Recycling market include advancements in recycling technologies, increasing urbanization leading to more scrap generation, and growing partnerships between recycling firms and manufacturers to ensure a steady supply of recycled materials.

What trends are shaping the United States Non-Ferrous Scrap Recycling market?

Trends shaping the United States Non-Ferrous Scrap Recycling market include the adoption of automated sorting technologies, the rise of circular economy initiatives, and increased investment in recycling infrastructure to enhance efficiency and capacity.

United States Non-Ferrous Scrap Recycling market

| Segmentation Details | Description |

|---|---|

| Material Type | Aluminum, Copper, Brass, Lead |

| End User | Manufacturers, Foundries, Scrap Dealers, Recyclers |

| Processing Method | Shredding, Melting, Sorting, Baling |

| Market Channel | Direct Sales, Online Platforms, Auctions, Brokers |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the United States Non-Ferrous Scrap Recycling Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at