444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview:

Flexographic printing is a widely adopted form of printing in the United States, offering versatile solutions for various industries. This printing technique utilizes flexible relief plates to transfer ink onto a substrate, making it suitable for printing on a wide range of materials such as plastic, paper, cardboard, and metal. The United States flexographic printing market has witnessed significant growth in recent years, driven by advancements in technology, increasing demand for packaging materials, and cost-effective production capabilities.

Meaning:

Flexographic printing, also known as flexo printing, is a modern printing method that utilizes flexible printing plates made of rubber or polymer material. The inked plates rotate on a cylinder, transferring the desired image or text onto the substrate. It is commonly used for high-volume production runs and is well-suited for printing on various materials, making it an ideal choice for the packaging industry.

Executive Summary:

The United States flexographic printing market has experienced robust growth due to the rising demand for efficient and sustainable printing solutions. With the increasing focus on eco-friendly packaging, flexo printing has emerged as a preferred choice for industries seeking cost-effective and environmentally conscious printing options. Additionally, the technology’s adaptability to various substrates and its ability to produce high-quality prints have contributed to its widespread adoption.

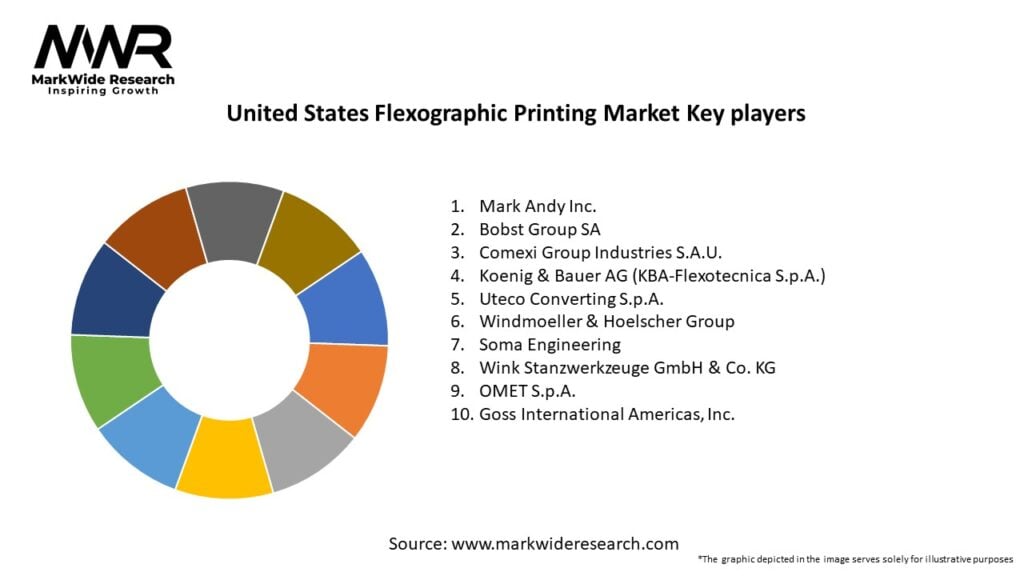

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics:

The United States flexographic printing market is characterized by dynamic trends and evolving consumer preferences. The market is driven by technological advancements, changing regulations, and the need for innovative and sustainable printing solutions. Competition among industry players remains fierce, prompting companies to continuously innovate and improve their offerings to meet customer demands.

Regional Analysis:

The flexographic printing market in the United States is distributed across various regions, with key printing hubs in states like California, Texas, Illinois, and New York. These regions have a high concentration of packaging and manufacturing industries, driving the demand for flexo printing services.

Competitive Landscape:

Leading Companies in the United States Flexographic Printing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation:

The United States flexographic printing market can be segmented based on:

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Market Key Trends:

Covid-19 Impact:

The COVID-19 pandemic had mixed effects on the flexographic printing market. While there was a temporary dip in demand due to supply chain disruptions and economic uncertainty, the increased demand for packaged goods during lockdowns provided some respite to the industry. Moreover, the emphasis on sustainable packaging solutions gained momentum during the pandemic, driving the adoption of flexographic printing for eco-friendly packaging options.

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The United States flexographic printing market is expected to maintain steady growth in the coming years, driven by advancements in technology, increasing demand for sustainable packaging, and the growth of the e-commerce sector. Printing companies that embrace innovation, sustainability, and customer-centricity will be well-positioned to thrive in this evolving market.

Conclusion:

The United States flexographic printing market continues to witness significant growth, driven by its versatility, cost-effectiveness, and ability to meet the demand for sustainable packaging solutions. As industries increasingly focus on eco-friendly practices, flexographic printing’s low environmental impact makes it an attractive choice. By embracing technological advancements, collaborating for innovation, and diversifying their product offerings, printing companies can unlock numerous opportunities and maintain a competitive edge in this dynamic market.

United States Flexographic Printing Market

| Segmentation Details | Description |

|---|---|

| Product Type | Water-Based Inks, Solvent-Based Inks, UV-Curable Inks, Electron Beam Inks |

| End User | Packaging, Labels, Corrugated, Flexible Packaging |

| Technology | Digital Flexo, Conventional Flexo, Hybrid Flexo, Inline Flexo |

| Application | Food Packaging, Beverage Packaging, Personal Care, Industrial Packaging |

Leading Companies in the United States Flexographic Printing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at