444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview:

The United States Contract Manufacturing Services Market has witnessed substantial growth in recent years, driven by increasing demand for cost-effective and efficient production solutions across various industries. Contract manufacturing services refer to the outsourcing of production processes to specialized third-party manufacturers. This arrangement allows companies to focus on core competencies, reduce production costs, and access advanced manufacturing technologies without making substantial investments. As a result, contract manufacturing services have become an integral part of the manufacturing landscape in the United States.

Meaning:

Contract manufacturing services involve the collaboration between companies (OEMs or Original Equipment Manufacturers) and contract manufacturers (CMs) to produce goods or components according to specified requirements. The OEMs provide the design, specifications, and sometimes raw materials, while the CMs handle the production and assembly processes. This partnership enables businesses to streamline their operations, mitigate risks, and gain a competitive advantage in the market.

Executive Summary:

The United States Contract Manufacturing Services Market has witnessed robust growth, driven by the need for efficient production solutions and cost optimization. Contract manufacturing allows companies to focus on their core competencies and leverage the expertise of specialized manufacturers. This report provides key insights into the market drivers, restraints, opportunities, regional analysis, competitive landscape, and future outlook. Additionally, it delves into the impact of the Covid-19 pandemic and presents key industry developments, SWOT analysis, and analyst suggestions.

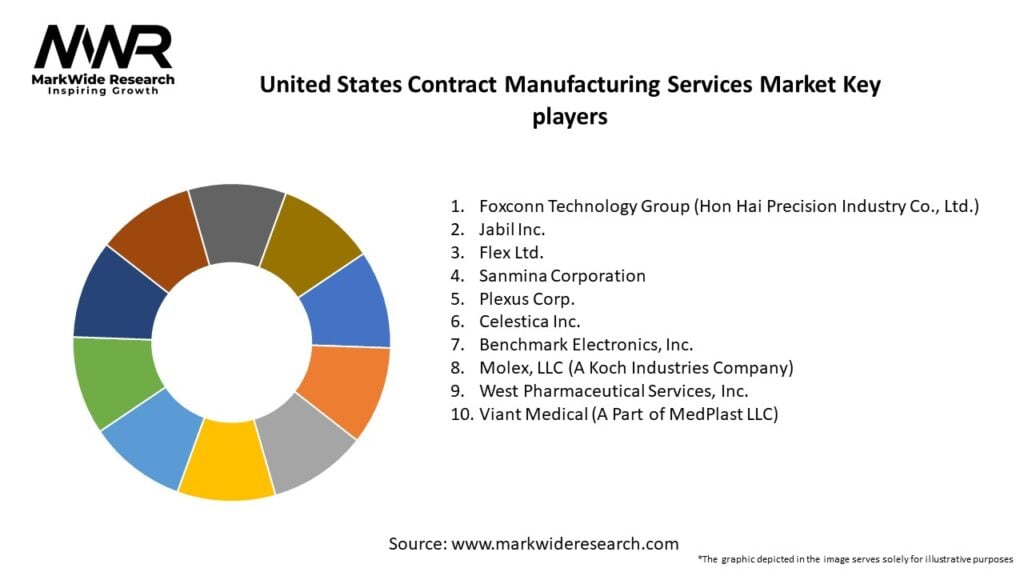

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics:

The United States Contract Manufacturing Services Market is characterized by dynamic interactions between market drivers, restraints, and opportunities. The outsourcing trend and technological advancements are driving market growth, while challenges related to quality control and intellectual property pose significant restraints. The market also offers exciting opportunities in pharmaceuticals, emerging technologies, green manufacturing, and defense sectors. To succeed in this market, companies must adapt to changing dynamics and leverage industry trends effectively.

Regional Analysis:

The contract manufacturing services market in the United States exhibits regional variations in terms of demand, manufacturing capabilities, and industry concentration. Key manufacturing hubs, such as California, Texas, and New York, attract a considerable portion of contract manufacturing activity. The Midwest is another significant region, hosting a diverse range of contract manufacturers serving multiple industries. The East Coast, particularly the Northeast, also boasts a substantial share of contract manufacturing services.

Competitive Landscape:

Leading Companies in the United States Contract Manufacturing Services Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

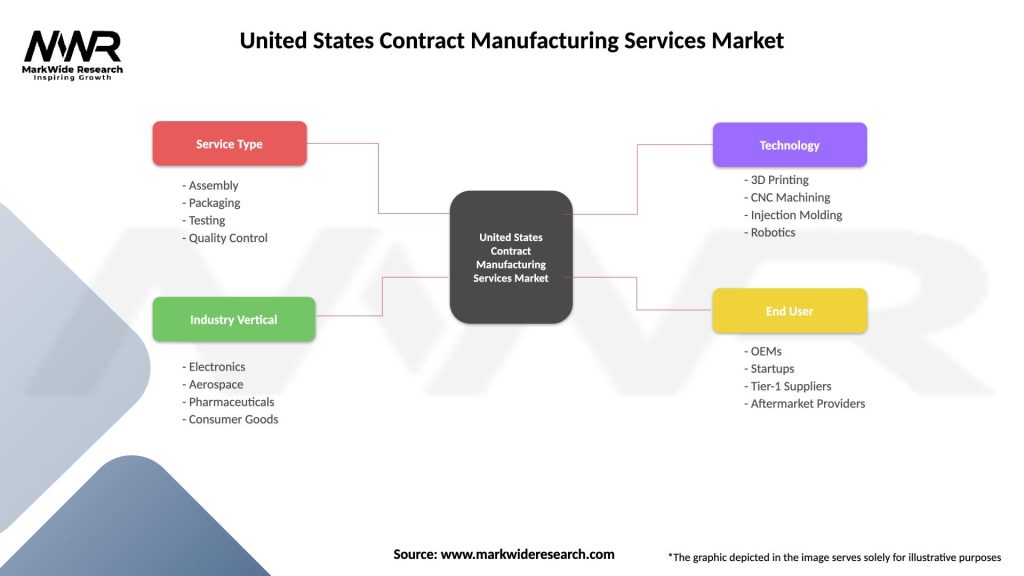

Segmentation:

The contract manufacturing services market in the United States can be segmented based on various factors, including industry verticals, services offered, and end-user applications. Common industry verticals availing contract manufacturing services include pharmaceuticals, electronics, automotive, aerospace, consumer goods, and medical devices. Services offered may include design and prototyping, assembly, packaging, testing, and supply chain management.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends:

Covid-19 Impact:

The Covid-19 pandemic had a significant impact on the contract manufacturing services market in the United States. Initially, disruptions in the supply chain and manufacturing operations caused challenges for both OEMs and CMs. However, the pandemic also highlighted the importance of agile and flexible production solutions, leading to increased adoption of contract manufacturing services to meet dynamic market demands.

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The United States Contract Manufacturing Services Market is expected to witness continued growth in the coming years. The rising trend of outsourcing, coupled with technological advancements, will drive market expansion. The pharmaceutical industry’s continued growth and increasing adoption of IoT and Industry 4.0 technologies will further fuel demand. However, companies must address quality control challenges and intellectual property concerns to sustain growth.

Conclusion:

The United States Contract Manufacturing Services Market presents a lucrative opportunity for companies looking to optimize production processes, reduce costs, and access specialized capabilities. The market’s future looks promising, with the pharmaceutical and emerging technology sectors offering significant growth prospects. Embracing sustainability, implementing digital transformation, and focusing on quality control will be essential for industry participants to succeed in this competitive and dynamic market. As the market evolves, strategic partnerships and vertical integration are likely to shape the landscape, providing a win-win situation for both OEMs and contract manufacturers.

What is Contract Manufacturing Services?

Contract manufacturing services refer to the outsourcing of production processes to third-party companies that specialize in manufacturing goods. These services are commonly used in various industries, including electronics, pharmaceuticals, and consumer goods.

What are the key players in the United States Contract Manufacturing Services Market?

Key players in the United States Contract Manufacturing Services Market include Flex Ltd., Jabil Inc., and Celestica Inc. These companies provide a range of manufacturing services across different sectors, including electronics and medical devices, among others.

What are the growth factors driving the United States Contract Manufacturing Services Market?

The growth of the United States Contract Manufacturing Services Market is driven by factors such as the increasing demand for cost-effective manufacturing solutions, the need for specialized production capabilities, and the rising trend of outsourcing among companies looking to focus on core competencies.

What challenges does the United States Contract Manufacturing Services Market face?

Challenges in the United States Contract Manufacturing Services Market include supply chain disruptions, quality control issues, and the need for compliance with regulatory standards. These factors can impact the efficiency and reliability of contract manufacturing operations.

What opportunities exist in the United States Contract Manufacturing Services Market?

Opportunities in the United States Contract Manufacturing Services Market include the expansion of advanced manufacturing technologies, such as automation and IoT, and the growing demand for customized manufacturing solutions. These trends can lead to increased efficiency and innovation in production processes.

What trends are shaping the United States Contract Manufacturing Services Market?

Trends shaping the United States Contract Manufacturing Services Market include the rise of digital manufacturing, sustainability initiatives, and the integration of advanced technologies like AI and machine learning. These trends are transforming how companies approach contract manufacturing and production efficiency.

United States Contract Manufacturing Services Market

| Segmentation Details | Description |

|---|---|

| Service Type | Assembly, Packaging, Testing, Quality Control |

| Industry Vertical | Electronics, Aerospace, Pharmaceuticals, Consumer Goods |

| Technology | 3D Printing, CNC Machining, Injection Molding, Robotics |

| End User | OEMs, Startups, Tier-1 Suppliers, Aftermarket Providers |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the United States Contract Manufacturing Services Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at