444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The United Kingdom Factory Automation and Industrial Control Systems Market have undergone significant growth, driven by the manufacturing industry’s pursuit of efficiency, precision, and productivity. Automation and control systems play a pivotal role in optimizing manufacturing processes, reducing operational costs, and ensuring consistent product quality. The market’s expansion is fueled by the adoption of Industry 4.0 principles and the demand for smart and interconnected factories.

Meaning

Factory automation and industrial control systems encompass a wide range of technologies and solutions designed to streamline manufacturing operations. Automation involves the use of machines, robots, and computer systems to perform tasks traditionally carried out by humans. Industrial control systems manage and regulate processes, ensuring equipment operates efficiently and products meet desired specifications. These systems include programmable logic controllers (PLCs), human-machine interfaces (HMIs), and supervisory control and data acquisition (SCADA) systems.

Executive Summary

The United Kingdom Factory Automation and Industrial Control Systems Market are witnessing remarkable growth as manufacturers recognize the strategic importance of automation in enhancing competitiveness. This report provides a comprehensive overview of key market insights, including trends, drivers, challenges, and opportunities. The integration of IoT and data analytics, the emphasis on flexible manufacturing, and the role of automation in sustainability initiatives shape the market’s trajectory.

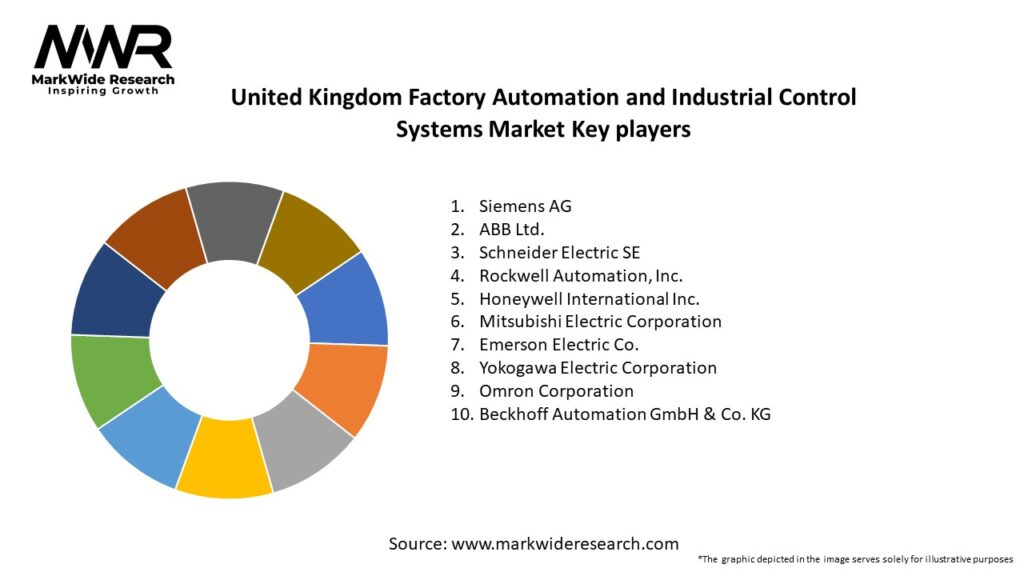

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Several factors are driving the growth of the United Kingdom Factory Automation and Industrial Control Systems market:

Technological Advancements: Continuous innovations in automation technologies such as robotics, AI, machine learning, and IoT are leading to increased adoption of factory automation solutions in various industries.

Government Support and Funding: The UK government has been actively promoting automation through initiatives like the UK’s Industrial Strategy, which encourages the adoption of automation to enhance competitiveness and sustainability across sectors.

Industry 4.0 and Smart Manufacturing: The global trend of Industry 4.0, which integrates digital technologies into manufacturing processes, is driving demand for automated systems that can communicate in real time, collect and analyze data, and optimize performance.

Labor Shortages and Efficiency Demands: The ongoing labor shortages, especially in skilled trades, and the need for operational efficiency are leading businesses to adopt automation technologies to maintain productivity levels without compromising quality.

Need for Improved Quality and Precision: Automation provides consistent quality, reducing human error and increasing precision in manufacturing processes. As the demand for high-quality products increases, automation is becoming a vital tool in maintaining product standards.

Market Restraints

Despite the significant growth potential, there are some challenges that the United Kingdom Factory Automation and ICS market faces:

High Initial Investment: The upfront cost of implementing automation systems, including robots, PLCs, and control systems, can be a major barrier for smaller manufacturers with limited budgets.

Integration Challenges: The integration of new automation systems with existing machinery and legacy systems can be complex, time-consuming, and costly, hindering the smooth adoption of automation solutions.

Skill Gap: There is a shortage of skilled workers with expertise in automation technologies, which can delay the adoption of factory automation systems and increase operational risks.

Security Concerns: As manufacturing systems become more connected and digitized, cybersecurity becomes a critical concern. The risk of cyber-attacks or data breaches can discourage some companies from fully embracing automated systems.

Resistance to Change: Resistance to change among workers and management can slow the adoption of factory automation systems, particularly in industries that have traditionally relied on manual labor or less sophisticated control systems.

Market Opportunities

The United Kingdom Factory Automation and ICS market offers significant growth opportunities:

Smart Factory Adoption: The increasing focus on creating smart factories with connected devices, real-time monitoring, and data analytics presents opportunities for companies to enhance efficiency and reduce costs using automation technologies.

Collaboration with AI and IoT: The integration of artificial intelligence (AI) and Internet of Things (IoT) with automation systems presents opportunities for more intelligent and autonomous operations. AI and IoT-enabled factory automation can optimize production, predict maintenance needs, and reduce downtime.

Automation in Small and Medium Enterprises (SMEs): While large industries have already adopted factory automation systems, there is still considerable opportunity to expand automation in small and medium enterprises, particularly in industries such as food processing, textiles, and pharmaceuticals.

Energy Efficiency Solutions: The increasing focus on sustainability and energy conservation provides an opportunity for the factory automation market to grow, as automation solutions help reduce energy consumption and minimize waste in production processes.

Advanced Robotics: The rise of collaborative robots (cobots) that work alongside human operators is presenting new opportunities for industries to automate complex tasks that were previously performed by humans, further driving the market for factory automation solutions.

Market Dynamics

The United Kingdom Factory Automation and ICS market is shaped by several key dynamics:

Technological Advancements in Robotics and AI: The continuous development of AI, machine learning, and advanced robotics is enhancing the capabilities of factory automation systems. These technologies enable machines to adapt to changing conditions and optimize production processes autonomously.

Shift Toward Smart and Connected Manufacturing: As manufacturers increasingly adopt Industry 4.0 principles, factory automation systems are evolving to integrate with enterprise resource planning (ERP) systems, supply chain management systems, and other IoT-based technologies to provide real-time data analysis and process optimization.

Cost Optimization and Productivity Gains: Businesses are increasingly looking to reduce costs and enhance productivity through automation. Factory automation solutions help minimize labor costs, increase throughput, and improve product consistency, providing a clear return on investment.

Regulatory Pressures and Compliance: The UK’s regulatory environment, including health, safety, and environmental standards, is driving manufacturers to invest in automation systems that can ensure compliance and reduce the risk of human error or accidents.

Regional Analysis

The United Kingdom Factory Automation and ICS market is influenced by regional factors:

Europe: Europe is one of the key regions for factory automation, with the UK being a prominent player in the market. The demand for automation solutions is driven by the automotive, food processing, and pharmaceutical sectors, which are increasingly adopting smart factory technologies.

North America: North America is also seeing significant growth in the factory automation market, particularly in the US and Canada, driven by advancements in robotics and AI integration.

Asia-Pacific: The Asia-Pacific region, particularly China and Japan, has been at the forefront of adopting automation technologies, and while this report focuses on the UK, companies in this region continue to be significant players in the global factory automation landscape.

Competitive Landscape

Leading Companies in the United Kingdom Factory Automation and Industrial Control Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The UK Factory Automation and ICS market can be segmented by:

By Type: Industrial Control Systems (ICS), Factory Automation Systems (FAS), Robotics and Automated Equipment.

By Application: Automotive, Food and Beverage, Pharmaceuticals, Chemicals, Electronics, Others.

By Region: England, Scotland, Wales, Northern Ireland.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The UK Factory Automation and ICS market provides several advantages:

Improved Operational Efficiency: Automation solutions improve production efficiency, reduce downtime, and optimize resource utilization, leading to cost savings and increased productivity.

Enhanced Quality and Consistency: Automation systems ensure that products are consistently manufactured to the same standards, improving quality and minimizing human errors.

Safety and Compliance: Automated systems help ensure compliance with health and safety regulations, reducing the risk of accidents and improving worker safety.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has influenced the United Kingdom Factory Automation and Industrial Control Systems Market in various ways. The disruption to global supply chains initially impacted manufacturing operations and component availability. However, the pandemic highlighted the importance of automation and remote monitoring for maintaining production continuity. The adoption of digital solutions and virtual commissioning gained prominence as manufacturers adapted to changing circumstances.

Key Industry Developments

The United Kingdom Factory Automation and Industrial Control Systems Market has witnessed significant developments that shape its trajectory. The integration of AI and machine learning into control systems enhances predictive analytics and process optimization. Collaborations between manufacturers and technology providers lead to the development of Industry 4.0 solutions that enable smart factories. The growth of edge computing facilitates real-time data processing and reduces latency in control systems.

Analyst Suggestions

Industry analysts offer valuable suggestions to navigate the evolving United Kingdom Factory Automation and Industrial Control Systems Market. Manufacturers should prioritize comprehensive system integration and data security measures to ensure the smooth operation of automated processes. Technology providers should focus on user-friendly interfaces and intuitive programming tools that enable efficient configuration and maintenance. Collaborative partnerships between academia, research institutions, and industry stakeholders foster innovation and address challenges.

Future Outlook

The future of the United Kingdom Factory Automation and Industrial Control Systems Market is promising, driven by the continuous evolution of manufacturing technology and the pursuit of efficiency. As the concept of smart factories gains momentum and Industry 4.0 principles become standard practice, the demand for advanced automation and control systems will continue to rise. The integration of AI, IoT, and data analytics will shape the manufacturing landscape, enabling manufacturers to produce high-quality products with precision and sustainability.

Conclusion

In conclusion, the United Kingdom Factory Automation and Industrial Control Systems Market’s growth story is intertwined with the transformation of manufacturing into a digitally connected and efficient endeavor. Automation and control systems not only optimize processes but also empower manufacturers to adapt to changing consumer demands and market trends. By embracing innovation, collaboration, and sustainability, stakeholders in the market can play a pivotal role in shaping the future of manufacturing in the United Kingdom.

United Kingdom Factory Automation and Industrial Control Systems Market

| Segmentation Details | Description |

|---|---|

| Product Type | Programmable Logic Controllers, Human-Machine Interfaces, Sensors, Drives |

| Technology | Industrial Internet of Things, Cloud Computing, Edge Computing, Artificial Intelligence |

| End User | Manufacturing, Oil & Gas, Food & Beverage, Pharmaceuticals |

| Application | Process Automation, Quality Control, Predictive Maintenance, Asset Management |

Leading Companies in the United Kingdom Factory Automation and Industrial Control Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at