444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Super-hard Material market has emerged as a revolutionary sector within the materials industry, offering cutting-edge solutions for various applications. These materials possess exceptional hardness, wear resistance, and thermal stability, making them indispensable in demanding environments. From industrial tools to electronic components, super-hard materials have become the preferred choice for manufacturers seeking unparalleled performance and longevity.

Meaning

Super-hard materials refer to a class of advanced materials with hardness levels surpassing traditional engineering materials like metals and ceramics. The most prominent examples include polycrystalline diamond (PCD) and cubic boron nitride (CBN), which exhibit outstanding hardness and are frequently used in cutting, grinding, and drilling applications.

Executive Summary

The Super-hard Material market has experienced exponential growth in recent years, driven by the expanding industrial and technological landscape. The global market size is projected to reach unprecedented heights, driven by the rising demand for durable and efficient tools and components across multiple sectors.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Super-hard Material market is a dynamic landscape influenced by technological advancements, market trends, and changing end-user preferences. The demand for super-hard materials is expected to maintain an upward trajectory due to their unparalleled performance in various applications.

Regional Analysis

North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa constitute the primary regions in the super-hard material market. Asia Pacific holds the largest market share due to the thriving manufacturing and construction sectors in countries like China and India.

Competitive Landscape

Leading Companies in the Super-hard Material Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The market is segmented based on material type, end-use industry, and application. The material type includes polycrystalline diamond (PCD), cubic boron nitride (CBN), and others. Industries such as automotive, aerospace, electronics, and construction are the primary end-users.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has disrupted various industries, including the super-hard material market. The slowdown in manufacturing and construction activities during lockdowns resulted in a temporary decline in demand. However, with economies recovering, the market is expected to regain momentum.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Super-hard Material market is poised for substantial growth in the coming years. The increasing demand for high-performance tools and components across various industries, coupled with ongoing advancements in material technology, will propel the market to new heights.

Conclusion

The Super-hard Material market is a critical segment within the materials industry, revolutionizing manufacturing and machining processes. With its exceptional hardness and performance, the market is expected to witness remarkable growth in the foreseeable future. Industry players should focus on innovation, strategic partnerships, and diversification to capitalize on the vast opportunities offered by this thriving sector.

What is Super-hard Material?

Super-hard materials are substances that possess exceptional hardness and resistance to deformation. They are commonly used in applications such as cutting tools, abrasives, and protective coatings due to their durability and strength.

What are the key players in the Super-hard Material market?

Key players in the Super-hard Material market include companies like Element Six, Sandvik, and De Beers Group, which are known for their innovations in synthetic diamond production and other super-hard materials, among others.

What are the main drivers of growth in the Super-hard Material market?

The growth of the Super-hard Material market is driven by increasing demand in industries such as aerospace, automotive, and electronics, where high-performance materials are essential for manufacturing precision components.

What challenges does the Super-hard Material market face?

Challenges in the Super-hard Material market include high production costs and the technical difficulties associated with processing these materials. Additionally, competition from alternative materials can hinder market growth.

What opportunities exist in the Super-hard Material market?

Opportunities in the Super-hard Material market include advancements in nanotechnology and the development of new applications in fields like medical devices and renewable energy, which could expand the market significantly.

What trends are shaping the Super-hard Material market?

Trends in the Super-hard Material market include the increasing use of super-hard materials in additive manufacturing and the growing focus on sustainability, as companies seek eco-friendly production methods and materials.

Super-hard Material market

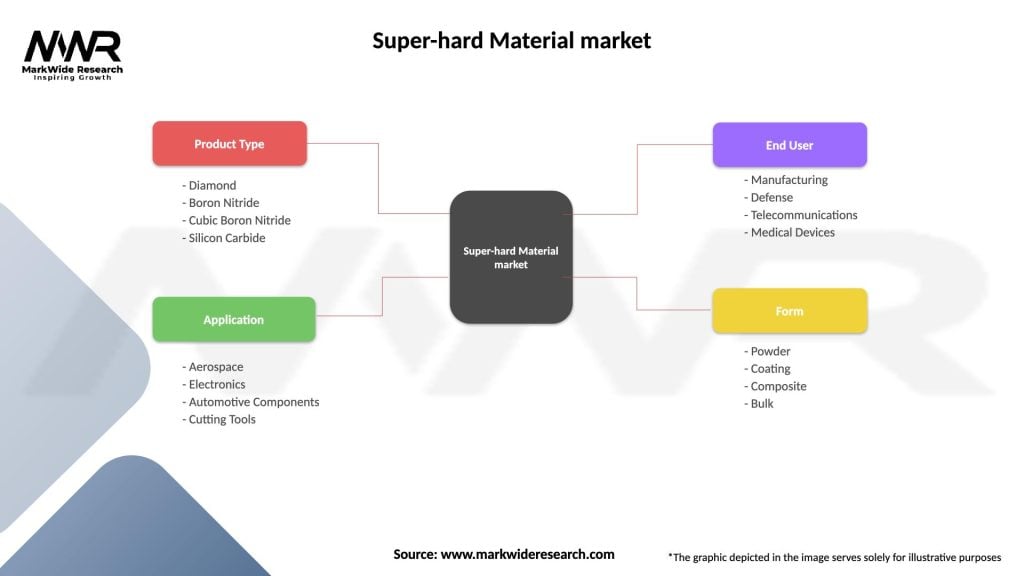

| Segmentation Details | Description |

|---|---|

| Product Type | Diamond, Boron Nitride, Cubic Boron Nitride, Silicon Carbide |

| Application | Aerospace, Electronics, Automotive Components, Cutting Tools |

| End User | Manufacturing, Defense, Telecommunications, Medical Devices |

| Form | Powder, Coating, Composite, Bulk |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at