444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

In the ever-evolving world of coatings, Powder In-mold Coatings have emerged as a cutting-edge solution that combines convenience and efficiency. These coatings offer significant advantages over conventional liquid coatings, making them increasingly popular in various industries. This comprehensive report delves into the Powder In-mold Coatings market, analyzing its meaning, key market insights, drivers, restraints, opportunities, and dynamic trends that are shaping its growth trajectory. The report also includes a detailed regional analysis, competitive landscape, segmentation, and category-wise insights, providing a 360-degree view of the market.

Meaning

Powder In-mold Coatings refer to a specialized type of coating process wherein a dry powder is applied to a mold surface before the injection of the plastic or composite material. This powder adheres to the mold’s surface electrostatically, creating a uniform coating that seamlessly fuses with the molded part during the manufacturing process. The result is a durable and high-quality finish that exhibits exceptional resistance to abrasion, chemicals, and UV radiation.

Executive Summary

The Powder In-mold Coatings market has witnessed remarkable growth in recent years, driven by its unparalleled advantages and increasing applications across various end-use industries. This executive summary provides a concise overview of the market’s key highlights, including market size, growth rate, major players, and crucial trends that have influenced its growth.

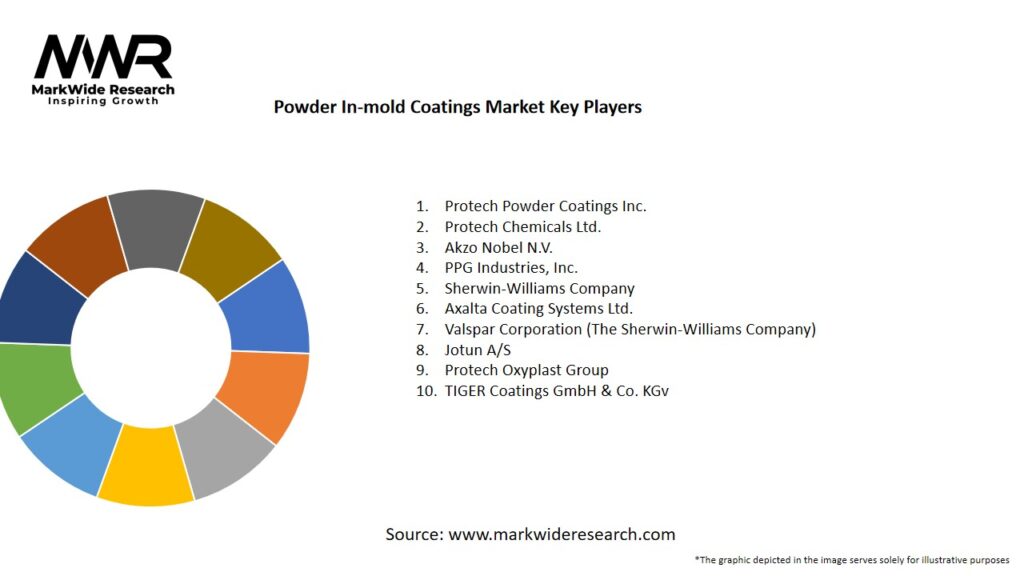

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Several key factors are driving the growth of the Powder In-Mold Coatings market:

Environmental Regulations: The increasing demand for eco-friendly and low-emission products is a major factor driving the adoption of Powder In-Mold Coatings. These coatings are solvent-free, reducing VOC emissions and contributing to sustainable manufacturing practices.

Durability and Performance: Powder coatings offer superior durability compared to traditional coatings. They provide enhanced resistance to wear, scratches, corrosion, and chemicals, making them ideal for demanding industrial applications such as automotive and electronics.

Cost Efficiency: The use of Powder In-Mold Coatings eliminates the need for additional surface finishing after molding, reducing the overall manufacturing costs and improving production efficiency.

Technological Advancements: Ongoing research and development are leading to the introduction of new and improved formulations of powder coatings that are compatible with different molding processes, expanding the scope of their application.

Market Restraints

While the Powder In-Mold Coatings market has significant growth potential, there are some challenges that could impact its expansion:

High Initial Equipment Cost: The equipment required for applying powder coatings, such as specialized spray booths and curing ovens, can be expensive, which could deter smaller manufacturers from adopting this technology.

Limited Awareness: In some regions, there is a lack of awareness regarding the benefits of Powder In-Mold Coatings, which can hinder the adoption of these coatings in certain markets.

Compatibility Issues: Powder coatings may not be compatible with all types of molding processes or materials, limiting their widespread adoption in certain industries.

Curing Challenges: The curing process required for powder coatings can sometimes be time-consuming and energy-intensive, which may reduce its attractiveness for industries with high production speed requirements.

Market Opportunities

The Powder In-Mold Coatings market presents various opportunities for growth:

Automotive Industry Demand: The automotive sector is increasingly adopting Powder In-Mold Coatings due to their superior durability, environmental benefits, and ability to meet the aesthetic and functional requirements of automotive parts.

Electronics and Consumer Goods: As the demand for high-performance and aesthetically appealing electronics and consumer goods rises, Powder In-Mold Coatings offer an ideal solution for coating molded components such as casings and housings.

Sustainable Manufacturing: The growing emphasis on sustainability in manufacturing presents an opportunity for companies in the Powder In-Mold Coatings market to capitalize on the increasing demand for eco-friendly coatings.

Expansion into Emerging Markets: The growing industrialization and urbanization in emerging markets present significant opportunities for the Powder In-Mold Coatings market as these regions invest in modernizing their manufacturing processes.

Market Dynamics

The dynamics of the Powder In-Mold Coatings market are influenced by a combination of technological, regulatory, and economic factors:

Technological Advancements: Innovations in powder coating formulations, including the development of coatings that work with different molding processes, are expanding the market’s scope and application areas.

Regulatory Pressure: Governments around the world are imposing stricter environmental regulations, which are encouraging manufacturers to adopt more sustainable and low-emission technologies such as Powder In-Mold Coatings.

Consumer Preference: Growing consumer preference for eco-friendly products is motivating manufacturers to adopt sustainable production practices, further boosting the demand for Powder In-Mold Coatings.

Global Economic Conditions: Economic growth in emerging markets, particularly in Asia-Pacific, is expected to drive demand for Powder In-Mold Coatings as industries in these regions modernize their manufacturing processes.

Regional Analysis

The Powder In-Mold Coatings market is experiencing varied adoption rates across different regions:

North America: The region has been a leader in the adoption of Powder In-Mold Coatings, driven by stringent environmental regulations, strong automotive and industrial sectors, and a focus on sustainable manufacturing practices.

Europe: Europe has seen substantial growth in the Powder In-Mold Coatings market, particularly in automotive and consumer goods industries, due to increasing regulations focused on reducing VOC emissions and fostering sustainable manufacturing.

Asia-Pacific: The Asia-Pacific region holds significant potential for growth, driven by industrial expansion in countries like China and India, where manufacturing is becoming increasingly modernized and environmentally conscious.

Latin America and Middle East & Africa: These regions are expected to experience moderate growth, with increasing awareness and demand for eco-friendly solutions driving adoption in key industries like automotive and electronics.

Competitive Landscape

Leading Companies in Powder In-mold Coatings Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Powder In-Mold Coatings market can be segmented based on:

Product Type: Epoxy, Polyester, Hybrid, Polyurethane.

Application: Automotive, Electronics, Consumer Goods, Industrial Equipment, Others.

End-User Industry: Automotive, Electronics, Industrial Manufacturing, Consumer Goods.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

Improved Durability: Powder In-Mold Coatings offer superior resistance to scratches, wear, and corrosion, increasing the longevity of molded products.

Eco-Friendly: These coatings are solvent-free, reducing VOC emissions and making them an environmentally friendly option compared to traditional coatings.

Cost Efficiency: Powder In-Mold Coatings reduce the need for post-mold finishing processes, leading to cost savings and enhanced operational efficiency.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Eco-Friendly Innovations: Ongoing innovations in sustainable powder coating formulations are shaping the market, with a strong focus on reducing environmental impact.

Technological Advancements: Continuous advancements in coating formulations are enabling Powder In-Mold Coatings to be compatible with different molding processes, driving their adoption across industries.

Covid-19 Impact

The Covid-19 pandemic had significant ramifications on various industries, including coatings. This section of the report analyzes the impact of the pandemic on the Powder In-mold Coatings market, discussing the challenges faced, adaptive measures taken, and the market’s resilience during these trying times.

Key Industry Developments

Key industry developments, such as technological advancements, product launches, and strategic collaborations, play a pivotal role in shaping the Powder In-mold Coatings market. This section highlights the most impactful developments that have influenced market growth.

Analyst Suggestions

Based on the comprehensive analysis, industry experts offer valuable suggestions to market participants and stakeholders. These suggestions aim to help them make informed decisions, navigate challenges, and capitalize on growth opportunities effectively.

Future Outlook

The future outlook section provides a glimpse into the prospective growth trajectory of the Powder In-mold Coatings market. Industry trends, technological advancements, and evolving consumer preferences are considered to paint a picture of what the market may look like in the coming years.

Conclusion

In conclusion, the Powder In-mold Coatings market has witnessed robust growth, driven by its eco-friendly nature, superior performance, and diverse applications across industries. With increasing awareness about sustainability and the growing demand for innovative coating solutions, the market is poised for further expansion. As manufacturers invest in research and development and collaborate to address challenges, the Powder In-mold Coatings market is set to shape the future of coatings technology, providing an array of benefits to industries and consumers alike.

What is Powder In-mold Coatings?

Powder In-mold Coatings are specialized coatings applied during the molding process to enhance the surface finish and durability of molded parts. They are commonly used in automotive, consumer goods, and industrial applications.

What are the key players in the Powder In-mold Coatings market?

Key players in the Powder In-mold Coatings market include companies like PPG Industries, Axalta Coating Systems, and BASF, among others. These companies are known for their innovative coating solutions and extensive product portfolios.

What are the growth factors driving the Powder In-mold Coatings market?

The growth of the Powder In-mold Coatings market is driven by increasing demand for lightweight materials in the automotive industry, advancements in coating technologies, and a growing focus on sustainability in manufacturing processes.

What challenges does the Powder In-mold Coatings market face?

Challenges in the Powder In-mold Coatings market include the high initial costs of equipment and the need for skilled labor to apply these coatings effectively. Additionally, competition from alternative coating methods can pose a challenge.

What opportunities exist in the Powder In-mold Coatings market?

Opportunities in the Powder In-mold Coatings market include the expansion of applications in the electronics and construction sectors, as well as the development of eco-friendly coating solutions that meet regulatory standards.

What trends are shaping the Powder In-mold Coatings market?

Trends in the Powder In-mold Coatings market include the increasing adoption of automation in the coating process, the rise of custom color formulations, and a growing emphasis on reducing environmental impact through sustainable practices.

Powder In-mold Coatings market

| Segmentation Details | Description |

|---|---|

| Product Type | Thermosetting, Thermoplastic, Hybrid, Specialty |

| End Use Industry | Automotive, Consumer Goods, Electronics, Industrial |

| Application | Furniture, Appliances, Automotive Parts, Packaging |

| Technology | Electrostatic Spray, Manual Application, Automated Systems, Others |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in Powder In-mold Coatings Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at