444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview:

The North America Oil Condition Monitoring Services market is an essential sector within the oil and gas industry, focused on monitoring and analyzing the condition of lubricants and machinery used in the extraction, refining, and distribution of oil. These services play a crucial role in ensuring the efficient and reliable operation of equipment, reducing maintenance costs, and preventing costly breakdowns. By closely monitoring the health of critical components, oil condition monitoring services enable companies to optimize their operations and extend the lifespan of equipment, ultimately enhancing productivity and profitability.

Meaning:

Oil Condition Monitoring Services involve the regular analysis of lubricants and equipment used in the oil and gas industry to assess their health and performance. Through various testing methods and data analysis, these services help identify potential issues and recommend corrective measures to maintain the optimal functioning of machinery.

Executive Summary:

The North America Oil Condition Monitoring Services market has witnessed steady growth over the years due to the increasing focus on equipment reliability and maintenance cost reduction. The demand for these services has been driven by the need to ensure the smooth operation of critical equipment and prevent unplanned downtime. The market has seen advancements in predictive maintenance technologies, allowing companies to adopt a proactive approach to equipment maintenance.

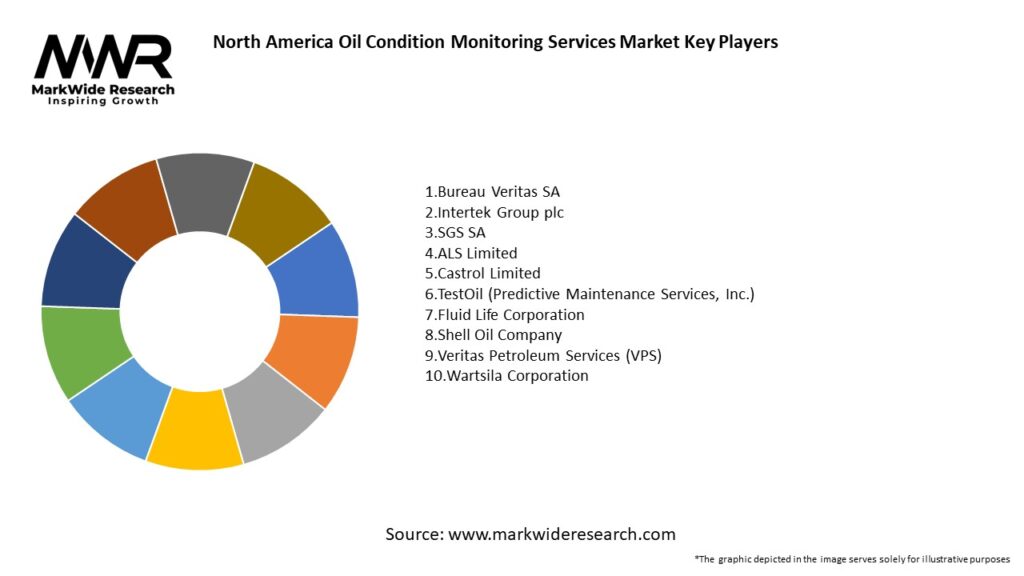

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics:

The North America Oil Condition Monitoring Services market is influenced by several factors, including industry trends, technological advancements, regulatory changes, and the overall economic climate. The emphasis on preventive maintenance, data-driven decision-making, and cost optimization are key driving forces in the market.

Regional Analysis:

The North America Oil Condition Monitoring Services market can be segmented into regions, including the United States, Canada, Mexico, and other Caribbean nations. The United States, with its significant oil and gas industry, is the dominant market within the region.

Competitive Landscape:

Leading Companies in North America Oil Condition Monitoring Services Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation:

The North America Oil Condition Monitoring Services market can be segmented based on the type of monitoring services offered, such as on-site testing, laboratory analysis, and online monitoring. Additionally, segmentation by end-user industry, such as upstream exploration and production, refining, and midstream distribution, can provide valuable insights.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends:

Covid-19 Impact:

The Covid-19 pandemic had both positive and negative effects on the North America Oil Condition Monitoring Services market. While it led to some disruptions in operations, it also highlighted the importance of predictive maintenance and remote monitoring technologies to ensure operational continuity during crises.

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The North America Oil Condition Monitoring Services market is expected to experience steady growth in the coming years, driven by the increasing awareness of the benefits of predictive maintenance and data-driven decision-making. As technology continues to advance and industries prioritize equipment reliability and cost optimization, the demand for these services will likely expand further.

Conclusion:

The North America Oil Condition Monitoring Services market plays a pivotal role in ensuring the efficient and reliable operation of critical equipment within the oil and gas industry. By adopting proactive maintenance strategies, leveraging technological advancements, and embracing data-driven insights, companies can optimize their operations, reduce maintenance costs, and maximize asset performance. As the industry continues to evolve and prioritize preventive measures, the future outlook for oil condition monitoring services appears promising, with opportunities for continued growth and innovation.

What is Oil Condition Monitoring Services?

Oil Condition Monitoring Services involve the analysis and assessment of oil properties to ensure optimal performance and longevity of machinery. These services are crucial in industries such as manufacturing, automotive, and energy, where equipment reliability is essential.

What are the key players in the North America Oil Condition Monitoring Services market?

Key players in the North America Oil Condition Monitoring Services market include companies like Parker Hannifin Corporation, Spectro Scientific, and ExxonMobil, among others. These companies provide a range of monitoring solutions and technologies to enhance oil performance and equipment reliability.

What are the growth factors driving the North America Oil Condition Monitoring Services market?

The growth of the North America Oil Condition Monitoring Services market is driven by increasing demand for predictive maintenance, the need to reduce operational costs, and advancements in monitoring technologies. Industries such as automotive and manufacturing are particularly focused on improving equipment efficiency.

What challenges does the North America Oil Condition Monitoring Services market face?

Challenges in the North America Oil Condition Monitoring Services market include the high initial investment for monitoring equipment and the need for skilled personnel to interpret data. Additionally, varying regulations across industries can complicate compliance and standardization.

What opportunities exist in the North America Oil Condition Monitoring Services market?

Opportunities in the North America Oil Condition Monitoring Services market include the integration of IoT technologies for real-time monitoring and the growing emphasis on sustainability practices. Companies are increasingly looking to optimize oil usage and reduce waste, creating a demand for advanced monitoring solutions.

What trends are shaping the North America Oil Condition Monitoring Services market?

Trends in the North America Oil Condition Monitoring Services market include the adoption of AI and machine learning for predictive analytics and the increasing use of mobile applications for monitoring. These innovations are enhancing the accuracy and efficiency of oil condition assessments.

North America Oil Condition Monitoring Services market

| Segmentation Details | Description |

|---|---|

| Service Type | Vibration Analysis, Oil Analysis, Thermography, Ultrasonic Testing |

| End User | Manufacturing, Energy, Transportation, Marine |

| Technology | IoT Solutions, Predictive Analytics, Cloud Computing, Data Acquisition |

| Application | Equipment Monitoring, Predictive Maintenance, Asset Management, Condition Assessment |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in North America Oil Condition Monitoring Services Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at