444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

Latin America AMH Market refers to the Automated Material Handling (AMH) systems market in the Latin American region. AMH systems are automated solutions that help in the movement, storage, control, and protection of materials within a manufacturing, distribution, or warehouse facility. These systems play a crucial role in optimizing operations, improving efficiency, and reducing manual labor in various industries.

Meaning

The Latin America AMH Market encompasses a wide range of technologies and solutions designed to streamline material handling processes. It includes automated storage and retrieval systems (AS/RS), conveyor systems, robotics, sorting systems, automated guided vehicles (AGVs), and warehouse management systems (WMS). These advanced technologies enable seamless material flow, real-time tracking, and efficient inventory management, leading to enhanced productivity and cost savings.

Executive Summary

The Latin America AMH Market has witnessed significant growth in recent years, driven by the increasing need for automation and optimization across industries. The region’s expanding manufacturing, e-commerce, and logistics sectors have fueled the demand for AMH systems. Additionally, factors such as rising labor costs, the need for error reduction, and the drive for operational efficiency have further propelled the market’s growth.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

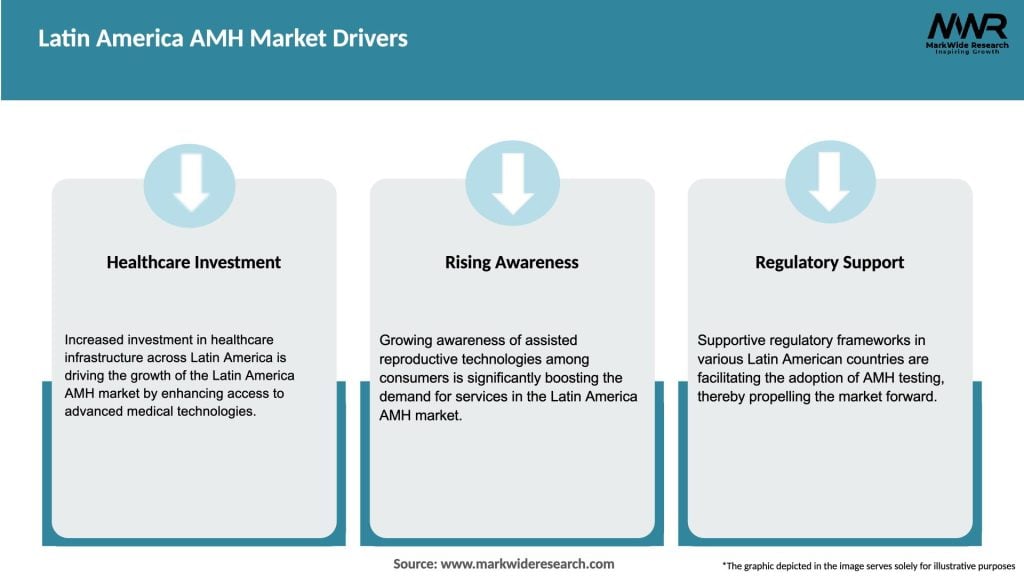

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Latin America AMH Market is driven by a combination of internal and external factors. The increasing need for operational efficiency, labor optimization, and error reduction, coupled with the growth of industries such as e-commerce and retail, fuels the market’s expansion. Technological advancements, integration of automation, and the adoption of AI and IoT solutions contribute to the market’s dynamics. However, challenges such as high initial costs, infrastructure limitations, and resistance to change pose constraints to the market’s growth. Nevertheless, opportunities arising from industry 4.0, government initiatives, and investments in the logistics sector create a positive outlook for the market in the region.

Regional Analysis

The Latin America AMH Market is analyzed based on key countries in the region, including Brazil, Mexico, Argentina, and Chile. Brazil holds a significant share due to its robust manufacturing sector and the presence of major e-commerce players. Mexico is witnessing rapid growth, driven by the expanding automotive industry and the rise in cross-border trade. Argentina and Chile are also experiencing a surge in demand for AMH systems, primarily in the retail and logistics sectors. The market in Latin America shows promising growth potential across these key countries, driven by various industries and favorable market conditions.

Competitive Landscape

Leading Companies in the Latin America AMH Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Latin America AMH Market can be segmented based on technology, industry, and end-user.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has significantly impacted the Latin America AMH Market. While certain industries faced disruptions and temporary closures, others experienced a surge in demand, such as e-commerce and essential goods. The pandemic highlighted the importance of resilient and automated supply chains, leading to increased investments in AMH systems. Companies accelerated their digital transformation efforts and adopted contactless operations, further driving the market’s growth. The pandemic served as a catalyst for the adoption of AMH solutions and highlighted their role in ensuring business continuity and adaptability.

Key Industry Developments

Several key developments are shaping the future of the Latin American AMH market:

Analyst Suggestions

Future Outlook

The Latin America AMH Market is poised for significant growth in the coming years. The expanding e-commerce sector, increasing focus on automation, and government initiatives promoting industrial digitization will drive market expansion. Advancements in AI, robotics, and IoT will further enhance the capabilities of AMH systems, leading to improved operational efficiency and cost savings. Companies that invest in AMH solutions and adapt to changing market dynamics will gain a competitive edge and capitalize on the opportunities in the evolving landscape.

Conclusion

The Latin America AMH Market is witnessing substantial growth, driven by the need for operational efficiency, labor optimization, and improved customer service. Industries such as e-commerce, automotive, and retail are key contributors to market expansion. While challenges exist in terms of initial costs and resistance to change, opportunities arising from industry 4.0 and government initiatives create a favorable environment for market growth. With technological advancements, integration of AI and IoT, and the adoption of robotics, the future outlook for the Latin America AMH Market is promising. Companies that embrace automation, invest in tailored AMH solutions, and stay updated with market trends will thrive in the evolving landscape.

What is AMH?

AMH, or Anti-Müllerian Hormone, is a substance produced by the ovaries that is used as a marker for ovarian reserve in women. It plays a crucial role in reproductive health assessments and fertility treatments.

What are the key players in the Latin America AMH Market?

Key players in the Latin America AMH Market include Roche Diagnostics, Siemens Healthineers, and Abbott Laboratories, among others. These companies are involved in the development and distribution of AMH testing kits and related diagnostic services.

What are the growth factors driving the Latin America AMH Market?

The growth of the Latin America AMH Market is driven by increasing awareness of fertility issues, rising infertility rates, and advancements in reproductive technologies. Additionally, the growing demand for personalized medicine in reproductive health is contributing to market expansion.

What challenges does the Latin America AMH Market face?

The Latin America AMH Market faces challenges such as limited access to advanced healthcare facilities and disparities in healthcare quality across different regions. Furthermore, regulatory hurdles and varying levels of awareness about AMH testing can hinder market growth.

What opportunities exist in the Latin America AMH Market?

Opportunities in the Latin America AMH Market include the potential for expanding diagnostic services in emerging economies and the development of new AMH-based fertility treatments. Collaborations between healthcare providers and technology firms can also enhance service delivery.

What trends are shaping the Latin America AMH Market?

Trends shaping the Latin America AMH Market include the increasing integration of digital health solutions in fertility assessments and the growing emphasis on women’s health initiatives. Additionally, there is a rising interest in research related to AMH and its implications for reproductive health.

Latin America AMH Market

| Segmentation Details | Description |

|---|---|

| Product Type | Injectables, Biologics, Biosimilars, Generics |

| End User | Hospitals, Clinics, Pharmacies, Homecare |

| Application | Chronic Diseases, Infectious Diseases, Pain Management, Preventive Care |

| Delivery Mode | Oral, Injectable, Transdermal, Inhalation |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Latin America AMH Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at