444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Fabric cutting machines have emerged as essential tools in the textile industry, revolutionizing the way fabrics are cut, saving time and increasing precision. These machines are designed to automate the process of cutting textiles, providing efficient and accurate results, regardless of the fabric type or complexity. With advancements in technology, fabric cutting machines have become a crucial component of textile manufacturing, catering to the increasing demand for high-quality fabrics across various industries.

Meaning

Fabric cutting machines are mechanical devices that utilize various cutting mechanisms, such as laser cutting, rotary blade cutting, and ultrasonic cutting, to precisely cut fabrics according to predetermined patterns or designs. These machines offer a range of benefits, including increased productivity, reduced labor costs, improved accuracy, and enhanced overall efficiency. By automating the cutting process, fabric cutting machines eliminate human errors and ensure consistent quality, resulting in higher customer satisfaction.

Executive Summary

The fabric cutting machines market has witnessed significant growth in recent years, driven by the rising demand for customized and high-quality fabrics across industries such as apparel, automotive, home textiles, and others. These machines enable manufacturers to streamline their production processes, reduce material waste, and meet the ever-changing consumer demands effectively. With advancements in technology, fabric cutting machines are becoming more versatile, offering enhanced capabilities and functionalities.

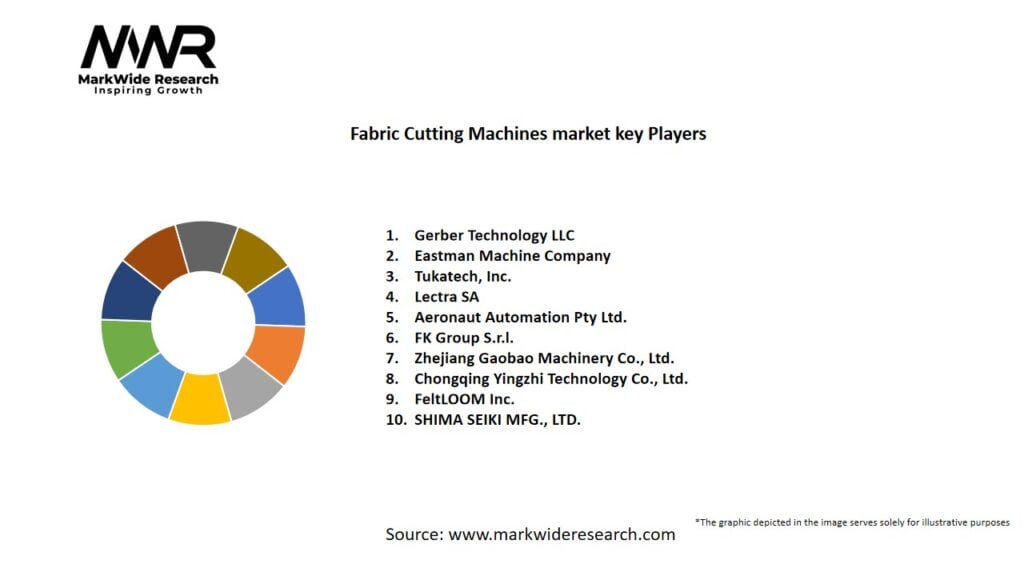

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The fabric cutting machines market is highly dynamic, driven by factors such as technological advancements, changing consumer preferences, and evolving industry trends. Manufacturers are focusing on developing cutting machines with advanced features, including improved cutting speed, higher accuracy, and intelligent automation capabilities. Additionally, partnerships and collaborations with textile manufacturers and suppliers are being formed to enhance product offerings and expand market reach.

Regional Analysis

The Asia-Pacific region dominates the fabric cutting machines market, accounting for the largest market share. Countries such as China, India, and Bangladesh are major textile manufacturing hubs, witnessing significant investments in textile infrastructure. North America and Europe also contribute significantly to the market, driven by the presence of established textile industries and the demand for high-quality fabrics.

Competitive Landscape

Leading Companies in Fabric Cutting Machines Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The fabric cutting machines market can be segmented based on the type of cutting mechanism, end-use industry, and geography.

By Cutting Mechanism:

By End-Use Industry:

By Geography:

Category-wise Insights

Apparel Industry: The apparel industry represents a significant segment for fabric cutting machines. These machines enable manufacturers to achieve precise cuts for various types of fabrics, including denim, silk, and synthetic materials. Fabric cutting machines equipped with laser cutting technology are widely used in the apparel industry due to their ability to handle complex designs and patterns.

Automotive Industry: Fabric cutting machines find applications in the automotive industry for cutting fabrics used in the interior of vehicles. These machines ensure precision and accuracy in cutting materials like upholstery fabrics, carpets, and seat covers. The automotive industry’s increasing focus on customization and luxury interiors has driven the demand for fabric cutting machines.

Home Textiles: Fabric cutting machines play a vital role in the production of home textiles such as curtains, beddings, and upholstery. These machines enable manufacturers to efficiently handle different fabric types and sizes, ensuring consistent quality and design accuracy. The growing demand for home textiles has contributed to the adoption of fabric cutting machines in this segment.

Industrial Fabrics: Fabric cutting machines are extensively used in the production of industrial fabrics, including technical textiles and protective clothing. These machines offer the flexibility to cut heavy-duty fabrics and materials such as Kevlar, fiberglass, and carbon fiber. The industrial fabrics segment presents significant opportunities for fabric cutting machine manufacturers.

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The fabric cutting machines market witnessed a temporary setback during the COVID-19 pandemic due to the disruption in the global textile supply chain and the closure of manufacturing facilities. However, the market recovered quickly as the demand for textiles rebounded, driven by the increased focus on comfortable home clothing and personal protective equipment (PPE). Fabric cutting machines played a crucial role in meeting the rising demand for fabrics used in face masks, medical gowns, and other PPE.

Key Industry Developments

Analyst Suggestions

Future Outlook

The fabric cutting machines market is expected to witness steady growth in the coming years. The increasing demand for customized and high-quality fabrics, coupled with advancements in cutting technologies, will drive market expansion. Adoption of Industry 4.0 technologies and penetration into emerging markets will present significant growth opportunities. However, manufacturers need to address challenges related to high initial investments and limited awareness to fully unlock the market’s potential.

Conclusion

Fabric cutting machines have transformed the textile industry by automating and streamlining the fabric cutting process. These machines offer numerous benefits, including increased productivity, reduced material waste, and improved accuracy. The market is driven by the demand for customized and high-quality fabrics, advancements in cutting technologies, and the integration of Industry 4.0 capabilities. The fabric cutting machines market presents opportunities for manufacturers to expand their presence in emerging markets and collaborate with textile industry stakeholders. To succeed in this dynamic market, manufacturers should focus on innovation, sustainability, and strategic partnerships, while addressing the challenges associated with initial investments and skillset requirements.

Fabric Cutting Machines market

| Segmentation Details | Description |

|---|---|

| Product Type | Laser Cutting Machines, Waterjet Cutting Machines, Plasma Cutting Machines, CNC Cutting Machines |

| Technology | Automatic, Semi-Automatic, Manual, Hybrid |

| End User | Textile Industry, Automotive Manufacturers, Aerospace Sector, Furniture Production |

| Application | Pattern Making, Prototype Development, Mass Production, Custom Fabrication |

Leading Companies in Fabric Cutting Machines Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at