444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

Intralogistics automation has revolutionized the way businesses handle their internal material flow and logistics operations. The Europe Intralogistics Automation Market refers to the adoption and implementation of automated systems and technologies in warehouses, distribution centers, and manufacturing facilities across European countries. This market is driven by the increasing need for streamlining operations, improving efficiency, reducing labor costs, and enhancing overall productivity.

Meaning

Intralogistics automation involves the use of robotics, conveyor systems, automated guided vehicles (AGVs), warehouse management systems (WMS), and other advanced technologies to automate various aspects of material handling, storage, picking, sorting, and transportation within a facility. These automated solutions enable seamless and optimized operations, leading to improved throughput, reduced errors, and enhanced customer satisfaction.

Executive Summary

The Europe Intralogistics Automation Market has experienced significant growth in recent years, driven by the increasing demand for efficient and cost-effective logistics solutions. The market is characterized by the presence of several key players offering a wide range of automation technologies and solutions. The need for faster order fulfillment, rising e-commerce activities, and the emergence of Industry 4.0 concepts are some of the factors fueling market growth.

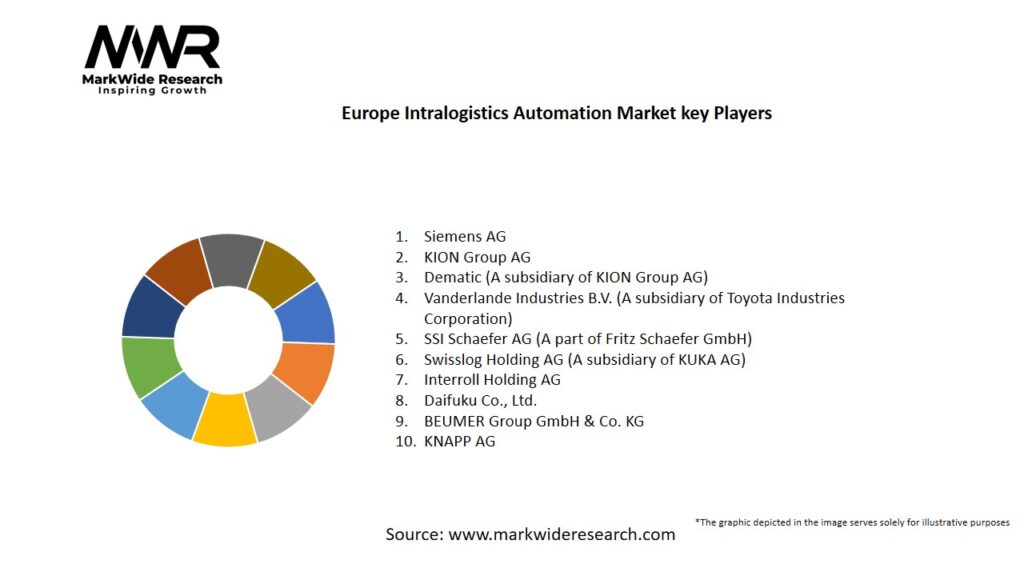

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The Europe Intralogistics Automation Market is driven by several key factors:

Market Restraints

Despite the positive growth prospects, the Europe Intralogistics Automation Market faces certain challenges:

Market Opportunities

The Europe Intralogistics Automation Market presents several opportunities for growth and innovation:

Market Dynamics

The Europe Intralogistics Automation Market is characterized by dynamic factors that influence its growth and evolution. These dynamics include market trends, regulatory developments, technological advancements, and changing customer expectations. To stay competitive, market players must monitor these dynamics and adapt their strategies accordingly.

Regional Analysis

The Europe Intralogistics Automation Market can be segmented into various regions, including:

Germany holds the largest market share in the region, driven by its robust manufacturing sector and early adoption of automation technologies. France and the United Kingdom are also significant contributors to the market due to their advanced logistics networks and high e-commerce activities.

Competitive Landscape

Leading Companies in Europe Intralogistics Automation Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Europe Intralogistics Automation Market can be segmented based on:

Segmentation allows businesses to target specific customer segments and tailor their offerings accordingly, optimizing their market presence.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The Europe Intralogistics Automation Market offers several benefits for industry participants and stakeholders:

SWOT Analysis

A SWOT analysis provides a comprehensive understanding of the Europe Intralogistics Automation Market:

Understanding the market’s strengths, weaknesses, opportunities, and threats enables businesses to develop effective strategies and mitigate potential risks.

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had both positive and negative impacts on the Europe Intralogistics Automation Market. On one hand, the acceleration of e-commerce activities and the need for contactless operations have driven increased demand for automation solutions. On the other hand, supply chain disruptions, budget constraints, and uncertainty have slowed down investment in automation projects. Overall, the pandemic has emphasized the importance of resilient and adaptable intralogistics systems.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the Europe Intralogistics Automation Market looks promising. The adoption of automation technologies is expected to increase as businesses seek to optimize their operations and remain competitive. With advancements in robotics, AI, and IoT, the intralogistics landscape will continue to evolve, offering new possibilities for efficiency, sustainability, and customer satisfaction.

Conclusion

The Europe Intralogistics Automation Market is witnessing steady growth, driven by the need for efficient, cost-effective, and scalable logistics solutions. Automation technologies such as robotics, AGVs, and WMS are revolutionizing intralogistics operations, enhancing efficiency, productivity, and customer satisfaction. While challenges exist, opportunities for innovation and growth are abundant. By embracing the latest trends, collaborating with key stakeholders, and investing in workforce training, businesses can navigate the dynamic market landscape and unlock the benefits of intralogistics automation in the years to come.

What is Intralogistics Automation?

Intralogistics Automation refers to the automated processes involved in the movement, storage, and management of goods within a facility. This includes technologies such as automated guided vehicles, conveyor systems, and warehouse management software.

What are the key players in the Europe Intralogistics Automation Market?

Key players in the Europe Intralogistics Automation Market include companies like KION Group, Dematic, and Swisslog, which provide innovative solutions for warehouse automation and material handling, among others.

What are the main drivers of the Europe Intralogistics Automation Market?

The main drivers of the Europe Intralogistics Automation Market include the increasing demand for efficiency in supply chain operations, the rise of e-commerce, and the need for real-time inventory management solutions.

What challenges does the Europe Intralogistics Automation Market face?

Challenges in the Europe Intralogistics Automation Market include high initial investment costs, the complexity of integrating new technologies with existing systems, and the need for skilled labor to manage automated systems.

What opportunities exist in the Europe Intralogistics Automation Market?

Opportunities in the Europe Intralogistics Automation Market include the growing trend of smart warehouses, advancements in robotics and AI, and the increasing focus on sustainability in logistics operations.

What trends are shaping the Europe Intralogistics Automation Market?

Trends shaping the Europe Intralogistics Automation Market include the adoption of IoT technologies for better data analytics, the rise of autonomous mobile robots, and the integration of machine learning for predictive maintenance.

Europe Intralogistics Automation Market

| Segmentation Details | Description |

|---|---|

| Technology | Automated Guided Vehicles, Robotics, Conveyor Systems, Warehouse Management Systems |

| End User | Manufacturing, Retail, E-commerce, Food & Beverage |

| Application | Order Fulfillment, Inventory Management, Material Handling, Packaging |

| Product Type | Automated Storage Systems, Sortation Systems, Picking Systems, Control Systems |

Leading Companies in Europe Intralogistics Automation Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at