444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The electric knife gate valve market is witnessing significant growth due to the increasing demand for efficient and reliable valve solutions in various industries. Electric knife gate valves are widely used in applications that require the isolation and control of fluids, such as wastewater treatment plants, power generation facilities, chemical processing plants, and mining operations. These valves offer several advantages over traditional gate valves, including precise control, low maintenance requirements, and enhanced safety features. As a result, the market for electric knife gate valves is expected to experience substantial growth in the coming years.

Meaning

Electric knife gate valves are a type of industrial valve that are specifically designed for the isolation and control of fluids. These valves feature a sharpened blade or “knife” that cuts through the fluid flow, allowing for precise control and shut-off. The electric actuator attached to the valve provides the necessary power to open and close the valve remotely, eliminating the need for manual operation. This automation feature makes electric knife gate valves ideal for applications that require frequent or precise control of fluid flow.

Executive Summary

The electric knife gate valve market is poised for significant growth in the forecast period. The demand for these valves is driven by the need for reliable and efficient fluid control solutions in various industries. Electric knife gate valves offer advantages such as precise control, low maintenance, and enhanced safety features, making them suitable for applications in wastewater treatment, power generation, chemical processing, and mining. The market is highly competitive, with several key players focusing on product innovation and technological advancements to gain a competitive edge. The regional analysis reveals that North America and Asia Pacific are expected to dominate the market, followed by Europe and other regions.

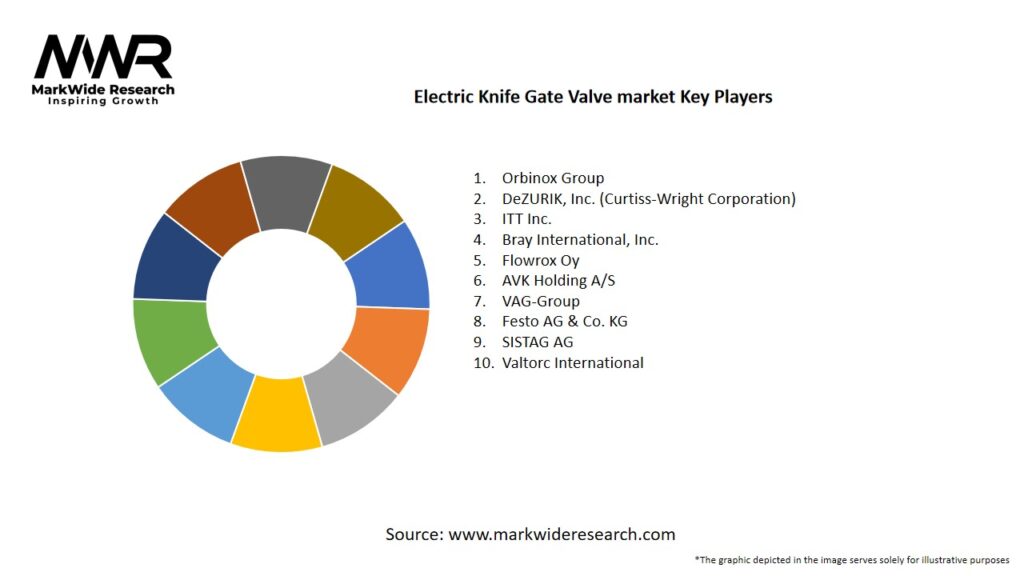

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

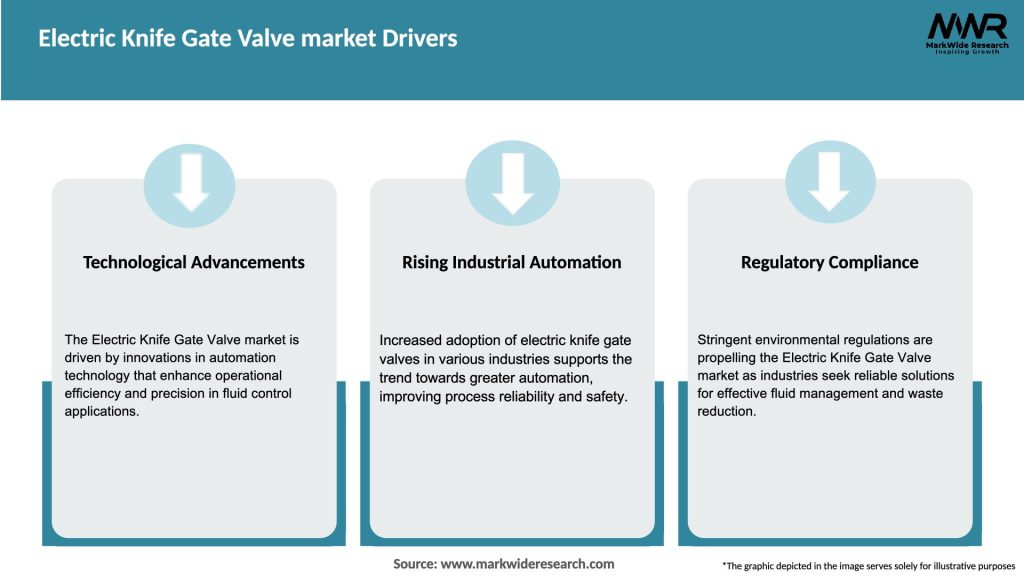

Market Drivers

The electric knife gate valve market is propelled by several key drivers. One of the major drivers is the increasing demand for efficient fluid control solutions in various industries. With the growing need for precise control and shut-off of fluids, electric knife gate valves offer an ideal solution. These valves provide accurate flow control, allowing operators to regulate the fluid flow according to specific requirements.

Additionally, electric knife gate valves require minimal maintenance compared to traditional gate valves. This low maintenance requirement reduces downtime and operational costs for industries. Moreover, electric knife gate valves are equipped with enhanced safety features such as emergency shut-off capabilities, which further contribute to their growing popularity.

Furthermore, the rising emphasis on water and wastewater treatment is expected to drive the demand for electric knife gate valves. With increasing environmental regulations and the need for sustainable solutions, industries are investing in advanced valve technologies to improve their wastewater treatment processes. Electric knife gate valves, with their precise control and efficient shut-off capabilities, are being widely adopted in wastewater treatment plants for effective fluid control.

Market Restraints

Despite the positive growth prospects, the electric knife gate valve market faces certain restraints that could hinder its progress. One of the key restraints is the high initial cost of these valves. Electric knife gate valves are relatively more expensive compared to traditional gate valves due to their advanced features and automation capabilities. This higher cost can be a deterrent for some industries, especially those with budget constraints or limited financial resources.

Another challenge for the market is the lack of awareness and knowledge about electric knife gate valves amongpotential end-users. Many industries may not be fully aware of the benefits and applications of electric knife gate valves. As a result, they may continue to rely on traditional gate valves or other types of valves, limiting the market growth for electric knife gate valves.

Additionally, the market may face challenges in terms of compatibility and integration with existing systems. Industries that already have established infrastructure and systems may hesitate to adopt electric knife gate valves if they require significant modifications or upgrades to accommodate these valves. Compatibility issues can slow down the adoption rate and hinder market growth.

Market Opportunities

The electric knife gate valve market presents several opportunities for growth and expansion. One of the key opportunities lies in the increasing focus on industrial automation and digitalization. As industries strive for more efficient and automated processes, the demand for electric knife gate valves is expected to rise. These valves can be seamlessly integrated into automated systems, offering precise control and remote operation capabilities.

Moreover, the growing emphasis on environmental sustainability and water conservation provides opportunities for the market. Electric knife gate valves play a crucial role in wastewater treatment plants, where effective fluid control is necessary to ensure proper treatment and discharge. With the increasing need for improved water management and conservation, the demand for electric knife gate valves in the water and wastewater industry is expected to increase.

Furthermore, the expansion of industries such as power generation, oil and gas, and chemical processing in emerging economies presents lucrative opportunities for market players. As these industries invest in infrastructure development and modernization, the demand for efficient fluid control solutions, including electric knife gate valves, is expected to surge.

Market Dynamics

The electric knife gate valve market is driven by a combination of market dynamics, including drivers, restraints, and opportunities. The increasing demand for efficient fluid control solutions, driven by industries such as wastewater treatment, power generation, chemical processing, and mining, acts as a major driver for the market. The precise control, low maintenance, and enhanced safety features offered by electric knife gate valves make them an attractive choice for end-users.

However, the market faces certain restraints, including the high initial cost of electric knife gate valves and the lack of awareness among potential end-users. The higher cost may discourage some industries from adopting these valves, while the lack of awareness may limit the market’s growth potential.

Despite these challenges, the market presents several opportunities for growth, such as the increasing focus on industrial automation and digitalization, the emphasis on environmental sustainability and water conservation, and the expansion of industries in emerging economies. These opportunities can be leveraged by market players to expand their market presence and gain a competitive edge.

Regional Analysis

The electric knife gate valve market can be analyzed based on regional segmentation, which includes North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Among these regions, North America and Asia Pacific are expected to dominate the market in terms of market share.

North America has a well-established industrial infrastructure and is a key market for industries such as wastewater treatment, power generation, and mining. The region’s strict environmental regulations drive the demand for efficient fluid control solutions, thereby boosting the market for electric knife gate valves.

Asia Pacific is witnessing rapid industrialization and infrastructure development, particularly in countries like China and India. The expansion of industries such as power generation, oil and gas, and chemical processing in this region is fueling the demand for electric knife gate valves. Additionally, the increasing focus on water and wastewater treatment in countries facing water scarcity issues presents significant opportunities for market growth in Asia Pacific.

Europe is another prominent market for electric knife gate valves, owing to the region’s stringent environmental regulations and the presence of well-established industries. The emphasis on sustainable solutions and water management drives the demand for these valves in Europe.

Latin America and Middle East & Africa are expected to witness steady growth in the electric knife gate valve market.The regions are experiencing infrastructural development and the expansion of industries, which will contribute to the demand for efficient fluid control solutions, including electric knife gate valves.

Competitive Landscape

Leading Companies in the Electric Knife Gate Valve Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

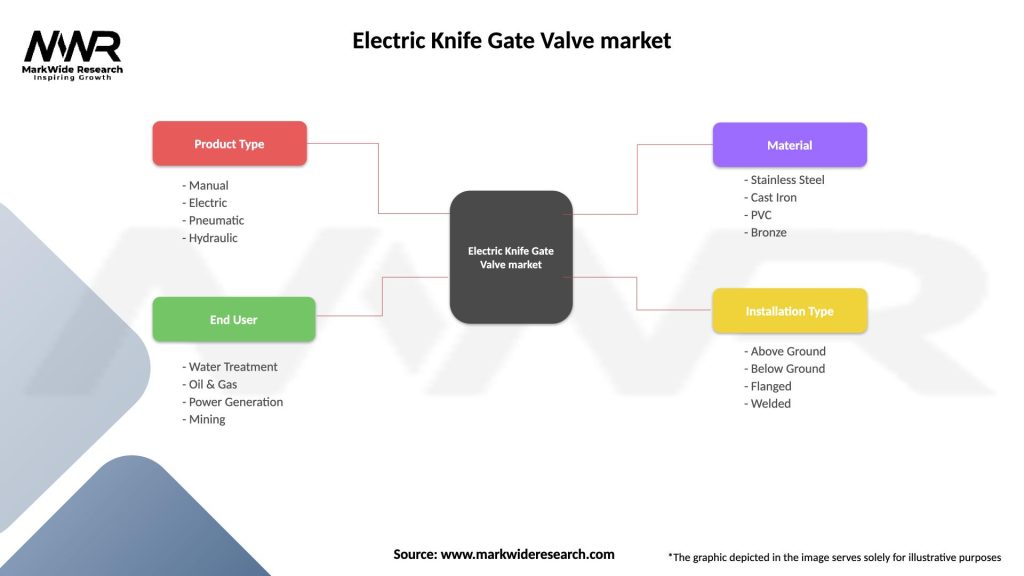

The electric knife gate valve market can be segmented based on various factors, including product type, application, end-user industry, and region.

By product type, the market can be segmented into electric actuated knife gate valves and pneumatic actuated knife gate valves. Electric actuated knife gate valves are expected to dominate the market, owing to their advantages of remote operation, precise control, and automation capabilities.

Based on application, the market can be segmented into wastewater treatment, power generation, chemical processing, mining, and others. Wastewater treatment is anticipated to be the largest application segment, driven by the increasing focus on water management and environmental regulations.

In terms of end-user industry, the market can be segmented into water and wastewater, power generation, oil and gas, chemical processing, mining, and others. The water and wastewater industry is expected to hold a significant share in the market due to the growing emphasis on efficient wastewater treatment and conservation.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholdersin the electric knife gate valve market can benefit from several key advantages. These benefits include:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

The electric knife gate valve market is influenced by several key trends that are shaping its growth and direction. These trends include:

Covid-19 Impact

The electric knife gate valve market, like many other industries, was affected by the Covid-19 pandemic. The pandemic led to disruptions in global supply chains, temporary shutdowns of manufacturing facilities, and reduced demand from end-user industries.

During the initial phase of the pandemic, many construction and infrastructure projects were put on hold, impacting the demand for electric knife gate valves. Moreover, industries such as oil and gas, mining, and manufacturing experienced a decline in production and operations, leading to a decreased demand for valve solutions.

However, as the situation improved and economic activities resumed, the market started to recover. The emphasis on infrastructure development, wastewater treatment, and industrial automation acted as driving factors for market growth. Industries recognized the importance of efficient fluid control solutions and increased their investments in valve technologies, including electric knife gate valves.

Additionally, the Covid-19 pandemic highlighted the significance of remote operation and automation capabilities in maintaining business continuity. Electric knife gate valves, with their remote operation features, gained traction as industries sought to minimize manual intervention and ensure uninterrupted operations.

Overall, while the pandemic initially posed challenges for the market, it also created opportunities for innovation and accelerated the adoption of advanced valve technologies.

Key Industry Developments

Analyst Suggestions

Based on market trends and dynamics, analysts suggest the following strategies for industry participants and stakeholders in the electric knife gate valve market:

Future Outlook

The electric knife gate valve market is expected to witness steady growth in the coming years. The increasing focus on industrial automation, infrastructure development, and environmental sustainability will drive the demand for efficient fluid control solutions, including electric knife gate valves.

Advancements in technology, such as automation, digitalization, and smart features, will continue to shape the market landscape. Integration of IIoT, AI, and ML technologies will enable predictive maintenance, remote monitoring, and enhanced control capabilities, further optimizing valve performance.

The expansion of end-user industries such as wastewater treatment, power generation, chemical processing, and mining will contribute to market growth. Additionally, emerging economies are investing in infrastructure development, creating new opportunities for electric knife gate valve manufacturers.

However, market players should remain vigilant of challenges such as intense competition and economic uncertainties. Volatility in raw material prices and potential trade restrictions can impact the cost structure of the industry. Therefore, maintaining cost-effective operations and focusing on product differentiation will be crucial for sustained growth.

Conclusion

In conclusion, the electric knife gate valve market is poised for growth, driven by factors such as industrial automation, infrastructure development, and sustainability initiatives. Industry participants and stakeholders who embrace innovation, customer-centric approaches, and strategic partnerships are likely to thrive in this evolving market landscape.

What is Electric Knife Gate Valve?

Electric Knife Gate Valves are specialized valves designed for controlling the flow of liquids and slurries in various industrial applications. They feature a sharp-edged gate that slices through the medium, making them ideal for handling thick or viscous materials.

What are the key players in the Electric Knife Gate Valve market?

Key players in the Electric Knife Gate Valve market include companies like Emerson Electric Co., Flowserve Corporation, and KSB SE & Co. KGaA, among others. These companies are known for their innovative valve solutions and extensive product offerings.

What are the growth factors driving the Electric Knife Gate Valve market?

The growth of the Electric Knife Gate Valve market is driven by increasing demand from industries such as wastewater treatment, mining, and pulp and paper. Additionally, advancements in automation and control technologies are enhancing the efficiency of these valves.

What challenges does the Electric Knife Gate Valve market face?

The Electric Knife Gate Valve market faces challenges such as the high initial cost of electric actuators and the need for regular maintenance. Furthermore, competition from alternative valve technologies can impact market growth.

What opportunities exist in the Electric Knife Gate Valve market?

Opportunities in the Electric Knife Gate Valve market include the growing trend towards automation in industrial processes and the increasing focus on energy-efficient solutions. Additionally, emerging markets present new avenues for expansion.

What trends are shaping the Electric Knife Gate Valve market?

Trends in the Electric Knife Gate Valve market include the integration of smart technologies for remote monitoring and control, as well as the development of more durable materials to enhance valve longevity. Sustainability initiatives are also influencing product design and manufacturing processes.

Electric Knife Gate Valve market

| Segmentation Details | Description |

|---|---|

| Product Type | Manual, Electric, Pneumatic, Hydraulic |

| End User | Water Treatment, Oil & Gas, Power Generation, Mining |

| Material | Stainless Steel, Cast Iron, PVC, Bronze |

| Installation Type | Above Ground, Below Ground, Flanged, Welded |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Electric Knife Gate Valve Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at