444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The drilling machines market is a rapidly growing industry that plays a crucial role in various sectors such as construction, mining, oil and gas, manufacturing, and infrastructure development. Drilling machines are power tools used for creating holes in different materials such as metal, wood, concrete, and plastic. These machines are available in various sizes and types, including portable drilling machines, radial drilling machines, magnetic drilling machines, and automatic drilling machines.

The market for drilling machines has witnessed significant growth in recent years due to increasing industrialization and infrastructure development across the globe. The demand for drilling machines is driven by the need for efficient hole drilling operations in industries such as construction, manufacturing, and oil exploration. Additionally, technological advancements, such as computer numerical control (CNC) drilling machines, have improved the precision and efficiency of drilling operations, further fueling market growth.

Meaning

Drilling machines are mechanical devices used for creating holes in different materials. They consist of a motor, spindle, and a drill bit, which rotates at high speeds to penetrate the material and create a hole. Drilling machines can be operated manually or automatically, depending on the complexity of the drilling task and the desired precision. These machines find applications in various industries, including construction, manufacturing, mining, and oil and gas exploration.

Executive Summary

The drilling machines market has experienced significant growth in recent years, driven by the increasing demand for hole drilling operations in industries such as construction, manufacturing, and oil and gas. The market is characterized by the presence of several key players offering a wide range of drilling machines with varying capacities and functionalities. Technological advancements, such as CNC drilling machines, have further boosted market growth by improving drilling precision and efficiency. The market is expected to witness sustained growth in the coming years, driven by ongoing industrialization and infrastructure development projects worldwide.

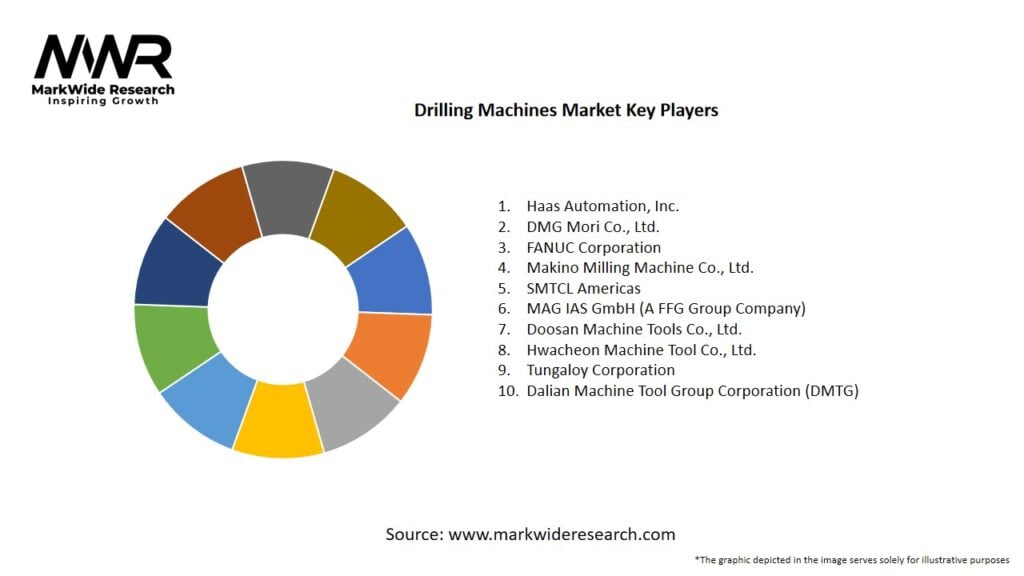

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The drilling machines market is characterized by dynamic factors that influence its growth and evolution. The key dynamics include market drivers, market restraints, and market opportunities.

The market drivers, such as industrialization, infrastructure development, and technological advancements, propel the demand for drilling machines. These factors create a favorable environment for market growth and attract investments in research and development to introduce innovative drilling solutions.

On the other hand, market restraints, including high initial costs, lack of skilled operators, and environmental concerns, pose challenges to the market. Manufacturers and stakeholders need to address these restraints to overcome barriers to market growth and ensure sustainability.

Market opportunities arise from emerging trends and developments, such as the expansion of oil and gas exploration activities, infrastructure development in emerging economies, technological advancements, focus on renewable energy, and retrofitting and refurbishment projects. These opportunities allow market players to capitalize on evolving market needs and offer tailored drilling solutions.

Overall, the drilling machines market is driven by the need for efficient and precise hole drilling operations in various industries. The market dynamics, including drivers, restraints, and opportunities, shape the growth trajectory of the market and present avenues for innovation and expansion.

Regional Analysis

The drilling machines market exhibits regional variations in terms of market size, growth rate, and key market players. The regional analysis helps understand the market dynamics specific to each region and identify growth opportunities.

The regional analysis provides insights into the market dynamics specific to each region and helps market players tailor their strategies to leverage the opportunities available in different geographies.

Competitive Landscape

Leading Companies in the Drilling Machines Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The drilling machines market can be segmented based on various factors, including product type, end-use industry, and geography. The segmentation helps understand the market dynamics and target specific customer segments effectively.

Based on product type, the drilling machines market can be segmented into:

Portable drilling machines are compact and lightweight, making them suitable for applications that require mobility and flexibility. Radial drilling machines are known for their versatility and are widely used in industries such as construction and manufacturing. Magnetic drilling machines use magnetic bases to secure the machine on metal surfaces, making them suitable for drilling holes in metal components. Automatic drilling machines offer automation features for high productivity and precision.

Based on end-use industry, the drilling machines market can be segmented into:

The construction industry is a major consumer of drilling machines, requiring them for various applications such as drilling holes for foundations, anchor bolts, and reinforcement. The manufacturing industry uses drilling machines for precision drilling operations in components and assemblies. The oil and gas industry relies on drilling machines for exploration, extraction, and well drilling operations. The mining industry uses drilling machines for exploration and extraction of minerals. Infrastructure development projects, including roads, bridges, and dams, also drive the demand for drilling machines.

Based on geography, the drilling machines market can be segmented into:

The segmentation helps market players understand regional market trends and tailor their strategies to target specific customer segments and geographical areas effectively.

Category-wise Insights

Each category of drilling machines offers unique features and capabilities to cater to specific customer requirements. The selection of the right drilling machine category depends on factors such as the nature of the drilling application, material to be drilled, required precision, and productivity needs.

Key Benefits for Industry Participants and Stakeholders

The drilling machines market offers several benefits for industry participants and stakeholders, including:

Industry participants and stakeholders, including drilling machine manufacturers, distributors, and end-users, can leverage these benefits to enhance their operations, improve efficiency, and gain a competitive edge in the market.

SWOT Analysis

A SWOT analysis provides an overview of the strengths, weaknesses, opportunities, and threats in the drilling machines market:

Understanding the strengths, weaknesses, opportunities, and threats helps market participants and stakeholders develop effective strategies to capitalize on market opportunities, mitigate risks, and stay competitive.

Market Key Trends

The drilling machines market is influenced by various key trends that shape its growth and development. Understanding these trends is crucial for market participants to stay ahead of the curve and adapt their strategies accordingly. Some of the key trends in the drilling machines market include:

These key trends reflect the evolving market landscape and customer demands. Market players need to stay updated with these trends and invest in research and development to introduce innovative drilling solutions that address the changing needs of industries.

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the drilling machines market, primarily due to the disruptions caused in various industries and the global economy. The pandemic led to temporary shutdowns of construction sites, manufacturing facilities, and infrastructure projects, which resulted in a decline in the demand for drilling machines.

The restrictions imposed on travel and transportation also affected the supply chain, leading to delays in the delivery of drilling machines and related components. Moreover, the uncertainty caused by the pandemic resulted in a cautious approach from end-users, leading to deferred investments and project delays.

However, the drilling machines market showed resilience and adapted to the changing market conditions. The construction and manufacturing industries gradually resumed operations, contributing to the recovery of the market. The increased focus on infrastructure development and the resumption of oil and gas exploration activities also played a significant role in driving the demand for drilling machines.

During the pandemic, there was a growing realization of the importance of automation and digitalization in maintaining productivity and operational efficiency. This trend led to increased interest in advanced drilling machines with automation features, as they minimize the need for manual labor and ensure social distancing protocols.

The pandemic also highlighted the need for sustainable practices and environmentally friendly drilling solutions. Market players are increasingly developing drilling machines that are energy-efficient, low-emission, and comply with environmental regulations.

Overall, while the Covid-19 pandemic posed challenges to the drilling machines market, it also accelerated certain trends such as automation, digitalization, and sustainability. The market is expected to recover as economic activities gradually normalize and industries invest in infrastructure development and expansion projects.

Key Industry Developments

The drilling machines market has witnessed several key industry developments that have shaped its growth and competitiveness. These developments include:

These industry developments contribute to the overall growth and competitiveness of the drilling machines market. Market players need to stay proactive and adapt to these developments to maintain a strong market position.

Analyst Suggestions

Based on the analysis of the drilling machines market, analysts suggest the following strategies for market participants:

By implementing these suggestions, market participants can navigate the evolving market landscape, seize opportunities, and stay ahead of the competition.

Future Outlook

The drilling machines market is expected to witness steady growth in the coming years. The market’s growth will be driven by factors such as the expansion of construction and infrastructure development projects, increasing demand from the manufacturing industry, and the exploration of new oil and gas reserves.

The adoption of advanced drilling technologies, automation, and digitalization will continue to shape the market’s future. Market players will focus on developing drilling machines with improved efficiency, precision, and sustainability features to meet evolving customer demands.

The renewable energy sector, including wind and solar power, will present significant opportunities for the drilling machines market. The installation of wind turbines, solar panels, and other renewable energy infrastructure requires drilling machines for foundation drilling and mounting structures.

However, market participants need to be mindful of challenges such as intense competition, pricing pressures, and environmental regulations. Investing in research and development, expanding product portfolios, and strengthening customer relationships will be crucial for sustainable growth in the market.

Overall, the future outlook for the drilling machines market is positive, driven by increasing industrialization, infrastructure development, and the need for efficient drilling operations across various industries. The market will continue to evolve with technological advancements and changing customer requirements, creating opportunities for innovation and market expansion.

Conclusion

The drilling machines market is a vital component of various industries, including construction, manufacturing, mining, and oil and gas. It offers efficient and precise hole drilling capabilities, contributing to productivity, operational efficiency, and the realization of infrastructure projects.

The market is characterized by various types of drilling machines, such as portable, radial, magnetic, and automatic drilling machines, each catering to specific drilling requirements. The market provides key benefits for industry participants and stakeholders, including increased productivity, improved precision, time and cost savings, versatility, and enhanced safety.

Drilling Machines Market

| Segmentation Details | Description |

|---|---|

| Product Type | Rotary Drilling, Percussion Drilling, Auger Drilling, Directional Drilling |

| Technology | Hydraulic, Electric, Pneumatic, Mechanical |

| End User | Construction, Mining, Oil & Gas, Utilities |

| Application | Foundation Drilling, Water Well Drilling, Geothermal Drilling, Environmental Drilling |

Leading Companies in the Drilling Machines Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at