444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Digital printing and dyeing machines are innovative devices used in the textile industry to print and dye fabrics with precision and efficiency. These machines have gained significant popularity in recent years due to their ability to produce high-quality and customized prints, eliminating the need for traditional printing methods that are time-consuming and less flexible. Digital printing and dyeing machines offer advantages such as reduced water and energy consumption, shorter production cycles, and enhanced design capabilities, making them a preferred choice for textile manufacturers worldwide.

Meaning

Digital printing and dyeing machines refer to technologically advanced equipment that enables the direct printing and dyeing of fabrics using digital techniques. Unlike traditional printing methods that involve creating screens or plates, digital printing and dyeing machines utilize computer-controlled processes to apply colors and patterns onto textiles. This technology allows for precise and detailed designs, unlimited color options, and the ability to print on various fabric types, including cotton, silk, polyester, and more. By eliminating the need for intermediaries and multiple production stages, digital printing and dyeing machines streamline the textile manufacturing process and offer improved efficiency and cost-effectiveness.

Executive Summary

The digital printing and dyeing machine market is experiencing rapid growth due to the increasing demand for customized and high-quality printed fabrics. The adoption of these machines has revolutionized the textile industry by providing greater design flexibility, faster production cycles, and reduced environmental impact. With advancements in digital printing technology and the integration of automation and artificial intelligence, the market is poised for further expansion in the coming years. However, the high initial cost of digital printing and dyeing machines and the need for skilled operators pose challenges to market growth. Overall, the market presents significant opportunities for manufacturers, designers, and stakeholders to capitalize on the growing demand for digital textile printing.

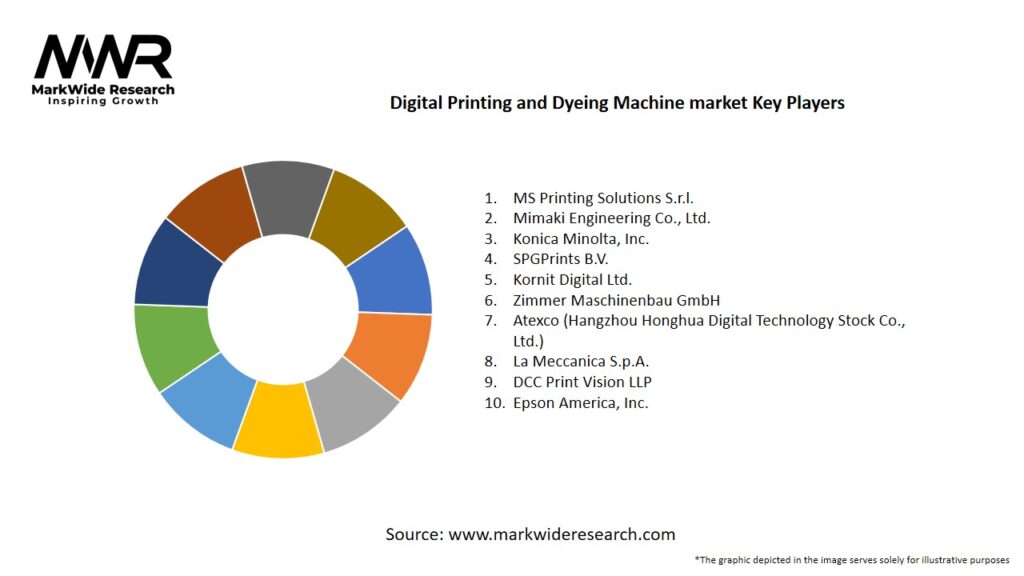

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The digital printing and dyeing machine market is driven by a combination of factors, including the increasing demand for customization, sustainability concerns, and technological advancements. Consumers’ desire for unique and personalized products is fueling the adoption of digital printing technologies, as it allows for the creation of one-of-a-kind designs and patterns. Additionally, the textile industry’s growing emphasis on sustainability and eco-friendly practices is driving manufacturers to adopt digital printing and dyeing machines, which offerreduced water and energy consumption compared to traditional methods.

Technological advancements in digital printing and dyeing machines are also playing a crucial role in market growth. The integration of automation and artificial intelligence in these machines enables improved accuracy, efficiency, and productivity. With the ability to automate various processes, such as color matching, fabric handling, and design placement, digital printing and dyeing machines are becoming more reliable and user-friendly.

However, certain challenges hinder the market’s growth. The high initial cost of digital printing and dyeing machines is a significant barrier for small and medium-sized textile manufacturers. Additionally, the need for skilled operators to operate and maintain these machines adds to the overall cost and may limit their adoption. Ensuring consistent color and print quality across different fabric types and maintaining proper machine calibration can also be challenging.

Regional Analysis

The digital printing and dyeing machine market exhibit regional variations in terms of market size, growth rate, and key players. The Asia Pacific region holds the largest market share due to its dominance in the textile industry. Countries like China, India, Bangladesh, and Vietnam are major textile manufacturing hubs, driving the demand for digital printing and dyeing machines. The presence of a large consumer base, coupled with rising disposable incomes and changing fashion trends, further contributes to the market’s growth in this region.

North America and Europe also play significant roles in the digital printing and dyeing machine market. These regions have a strong presence of fashion and apparel industries, which are increasingly adopting digital printing technologies. The demand for sustainable and eco-friendly textile production is particularly high in these regions, further propelling the adoption of digital printing and dyeing machines.

Emerging markets in Latin America, the Middle East, and Africa are witnessing steady growth in the digital printing and dyeing machine market. These regions offer untapped potential with the presence of a growing textile industry and increasing consumer awareness regarding digital printing technologies. However, market growth in these regions may be influenced by factors such as infrastructure limitations, access to advanced technology, and economic stability.

Competitive Landscape

Leading Companies in the Digital Printing and Dyeing Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The digital printing and dyeing machine market can be segmented based on the following criteria:

Segmenting the market allows for a better understanding of specific customerneeds, preferences, and regional dynamics. Different machine types cater to specific applications, such as direct-to-garment printing or roll-to-roll printing, offering flexibility to manufacturers based on their requirements. The choice of technology, whether inkjet, laser, or thermal transfer, determines the print quality, speed, and compatibility with different fabric types.

The end-user segmentation highlights the diverse industries benefiting from digital printing and dyeing machines. Textile manufacturers are the primary users, employing these machines to streamline their production processes and meet the increasing demand for customized fabrics. The fashion and apparel industry utilize digital printing to create unique designs and patterns, while the home furnishings and interior design sectors leverage this technology for customized textile products.

Considering the fabric type is crucial, as different fabrics require specific printing and dyeing techniques. Cotton, silk, polyester, and blend fabrics are commonly used, and the ability of digital printing and dyeing machines to work seamlessly with these materials is a key consideration for textile manufacturers.

Lastly, analyzing the market regionally provides insights into geographical variations in demand, market maturity, and growth opportunities. Each region may have different market drivers, consumer preferences, and regulatory landscapes, which necessitate tailored strategies for market entry and expansion.

Category-wise Insights

The digital printing and dyeing machine market can be further analyzed based on specific categories to gain deeper insights into key trends and opportunities. The categories that provide valuable insights include:

Analyzing the market based on these categories provides a comprehensive understanding of the specific factors influencing each segment. It allows industry participants to identify niche opportunities, develop targeted marketing strategies, and address the unique challenges faced by different sectors within the digital printing and dyeing machine market.

Key Benefits for Industry Participants and Stakeholders

The digital printing and dyeing machine market offer several benefits for industry participants and stakeholders, including:

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis provides a comprehensive assessment of the digital printing and dyeing machine market:

Strengths:

Weaknesses:

Opportunities:

Threats:

Understanding these strengths, weaknesses, opportunities, and threats helps industry participants and stakeholders devise strategies to capitalize on market strengths, overcome weaknesses, seize opportunities, and mitigate potential threats.

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had both positive and negative impacts on the digital printing and dyeing machine market. The global textile industry experienceddisruptions in the supply chain, production, and demand during the pandemic. However, the crisis also accelerated certain trends and created new opportunities for the digital printing and dyeing machine market.

During the lockdowns and restrictions on physical retail, e-commerce platforms witnessed a surge in demand for online shopping, including customized textiles. This shift towards online channels benefited manufacturers equipped with digital printing and dyeing machines, as they could meet the rising demand for personalized products.

The pandemic also highlighted the importance of agility and flexibility in the textile industry. Traditional manufacturing methods faced challenges due to their reliance on lengthy and complex production processes. In contrast, digital printing and dyeing machines offered advantages such as shorter production cycles, reduced setup times, and the ability to quickly adapt to changing customer preferences.

Furthermore, sustainability emerged as a significant concern during the pandemic. Consumers became more conscious of the environmental impact of their purchasing decisions, leading to a greater demand for eco-friendly and sustainable products. Digital printing and dyeing machines, with their reduced water and energy consumption, align with these sustainability requirements and gained traction among environmentally conscious consumers.

On the other hand, the pandemic also posed challenges for the market. Supply chain disruptions and the economic downturn affected the overall textile industry, leading to decreased investments and delayed projects. The high initial cost of digital printing and dyeing machines became a significant barrier for some manufacturers facing financial constraints.

However, as the world recovers from the pandemic and economies stabilize, the digital printing and dyeing machine market is expected to regain momentum. The increased focus on sustainability, customization, and online retail channels will likely drive the demand for these machines in the post-pandemic era.

Key Industry Developments

Analyst Suggestions

Based on the market trends and developments, analysts suggest the following strategies for industry participants and stakeholders in the digital printing and dyeing machine market:

Future Outlook

The future outlook for the digital printing and dyeing machine market is promising. The market is expected to witness significant growth due to increasing demand for customization, sustainability, and improved production efficiency. Technological advancements will continue to drive innovation, with a focus on automation, AI integration, and enhanced print quality.

The expansion of e-commerce platforms and online custom printing services will provide new avenues for market growth, allowing manufacturers to reach a broader customer base. The integration of digital printing and dyeing machines with industry 4.0 technologies will enable seamless production processes, data-driven decision-making, and further optimization of resource utilization.

However, challenges such as the high initial cost of machines and the need for skilled operators will need to be addressed. Manufacturers should invest in developing cost-effective solutions and providing training programs to bridge the skills gap.

Overall, the digital printing and dyeing machine market is poised for substantial growth, driven by the increasing demand for customized and sustainable textile products. By embracing technological advancements, fostering collaborations, and adopting customer-centric strategies, industry participants can capitalize on the opportunities presented by this evolving market.

Conclusion

The digital printing and dyeing machine market is experiencing rapid growth, driven by the demand for customization, sustainability, and enhanced efficiency in textile manufacturing. These machines provide advantages such as design flexibility, reduced water and energy consumption, and faster production cycles.

Despite challenges such as the high initial cost and the need for skilled operators, the market offers significant opportunities for industry participants. Strategic partnerships, technological advancements, and expanding into emerging markets can drive market growth.

What is Digital Printing and Dyeing Machine?

Digital Printing and Dyeing Machine refers to advanced equipment used for printing and dyeing textiles using digital technology. This technology allows for precise color application and intricate designs, making it popular in the fashion and home textiles industries.

What are the key players in the Digital Printing and Dyeing Machine market?

Key players in the Digital Printing and Dyeing Machine market include Epson, Mimaki Engineering, and Durst Phototechnik, among others. These companies are known for their innovative technologies and contributions to the textile printing sector.

What are the growth factors driving the Digital Printing and Dyeing Machine market?

The growth of the Digital Printing and Dyeing Machine market is driven by the increasing demand for customized textiles, the rise of e-commerce in fashion, and advancements in printing technology that enhance efficiency and reduce waste.

What challenges does the Digital Printing and Dyeing Machine market face?

Challenges in the Digital Printing and Dyeing Machine market include high initial investment costs, the need for skilled operators, and competition from traditional printing methods that may offer lower costs for large runs.

What opportunities exist in the Digital Printing and Dyeing Machine market?

Opportunities in the Digital Printing and Dyeing Machine market include the growing trend of sustainable fashion, which encourages eco-friendly printing solutions, and the expansion of digital textile printing into new applications such as interior design and automotive textiles.

What trends are shaping the Digital Printing and Dyeing Machine market?

Trends in the Digital Printing and Dyeing Machine market include the integration of automation and artificial intelligence to streamline production processes, as well as the increasing use of water-based inks and dyes to promote sustainability in textile manufacturing.

Digital Printing and Dyeing Machine market

| Segmentation Details | Description |

|---|---|

| Product Type | Inkjet Printers, Dye Sublimation Printers, Direct-to-Garment Printers, Digital Textile Printers |

| Technology | Electrostatic, Thermal, UV-Curable, Laser |

| End User | Textile Manufacturers, Apparel Brands, Home Furnishing, Print Service Providers |

| Application | Fashion, Interior Decoration, Industrial Textiles, Promotional Products |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Digital Printing and Dyeing Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at