444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Composite materials testing is a critical process that plays a pivotal role in ensuring the safety, reliability, and performance of composite materials used across various industries. These materials, composed of two or more distinct components, are combined to form a new material with enhanced properties. The market for composite materials testing has witnessed substantial growth over the years, driven by the increasing demand for lightweight and high-strength materials in aerospace, automotive, construction, and wind energy sectors, among others.

Meaning

Composite materials testing refers to the examination and evaluation of composite materials to determine their mechanical, thermal, electrical, and chemical properties. The primary goal of testing is to ensure that these materials meet the required industry standards and regulatory guidelines. Through rigorous testing processes, manufacturers and end-users gain valuable insights into the structural integrity and overall performance of composite materials, facilitating informed decision-making.

Executive Summary

The composite materials testing market has experienced robust growth due to the surge in the adoption of composite materials across diverse industries. The demand for lightweight, durable, and high-performance materials has propelled the market forward. This report presents an in-depth analysis of the market’s key trends, drivers, restraints, opportunities, and regional dynamics. Additionally, it provides insights into the competitive landscape, segmentation, and the impact of the COVID-19 pandemic on the market.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

The global composite materials testing market is driven by several factors. The escalating demand for advanced materials in aerospace applications to reduce fuel consumption and enhance aircraft performance has significantly propelled the market growth. Moreover, the automotive industry’s increasing interest in using composite materials to manufacture lightweight and fuel-efficient vehicles has further boosted the demand for composite materials testing services.

Despite its promising growth, the composite materials testing market faces certain challenges. High costs associated with sophisticated testing equipment and procedures are limiting the market’s expansion, especially in emerging economies. Additionally, the lack of standardized testing procedures and regulations across different regions can hamper the market’s growth potential.

Emerging economies present significant opportunities for composite materials testing companies. The rapid industrialization, infrastructural development, and the growing adoption of composite materials in various applications in these regions are likely to fuel demand. Furthermore, advancements in non-destructive testing techniques and the rise of Industry 4.0 are expected to create new growth avenues for the market.

Market Dynamics

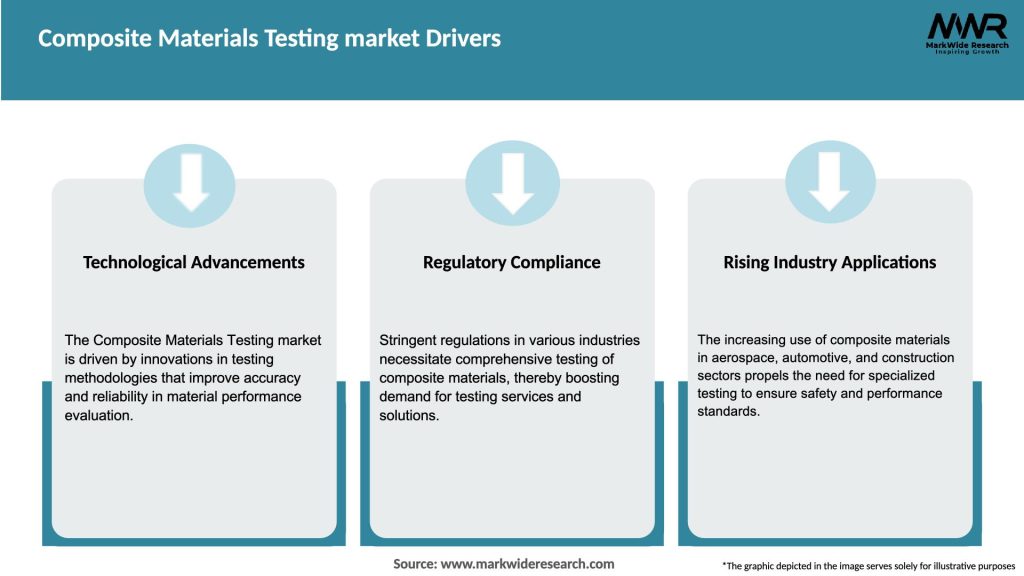

The composite materials testing market is influenced by various dynamic factors. Technological advancements in testing methods and equipment continue to shape the industry landscape. Additionally, partnerships, collaborations, and acquisitions among key players in the market are becoming increasingly prevalent, further intensifying competition.

Regional Analysis

The composite materials testing market is segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. North America and Europe dominate the market due to well-established aerospace and automotive industries. However, Asia Pacific is witnessing substantial growth, driven by rapid industrialization, urbanization, and increased infrastructure development in countries like China, India, and Japan.

Competitive Landscape

Leading Companies in the Composite Materials Testing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The market is segmented based on testing type, end-use industry, and geography. Testing types include mechanical testing, non-destructive testing, thermal testing, and others. Major end-use industries encompass aerospace & defense, automotive, construction, wind energy, and others.

Category-wise Insights

The aerospace and defense sector is one of the primary drivers of the composite materials testing market. Aircraft manufacturers and suppliers require stringent testing to ensure the safety and reliability of composite components used in aircraft construction. The demand for lightweight materials in the aerospace industry has further increased the need for advanced testing methods.

In the automotive sector, the adoption of composite materials is rising due to their potential to reduce vehicle weight and enhance fuel efficiency. Composite materials testing is essential to validate the structural integrity and performance of these materials in various automotive applications, such as body panels, chassis, and interiors.

Composite materials are increasingly being used in the construction industry to improve the structural strength and durability of buildings and infrastructure. Testing these materials helps ensure compliance with safety regulations and enhances the overall quality of construction projects.

The wind energy sector has witnessed a surge in the use of composite materials in wind turbine blades. Testing these large-scale structures is crucial to assess their fatigue resistance, ensuring the long-term reliability and efficiency of wind turbines.

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

The market is witnessing continuous advancements in testing technology, such as the integration of artificial intelligence and machine learning in testing equipment. These developments improve testing accuracy, efficiency, and data analysis capabilities.

With a growing focus on sustainability, the industry is shifting towards eco-friendly testing methods and equipment that have minimal environmental impact, aligning with the broader sustainability goals of various industries.

The adoption of Industry 4.0 principles in composite materials testing is gaining traction. Smart sensors and IoT-enabled devices are being incorporated into testing equipment to enable real-time monitoring and data analytics.

Covid-19 Impact

The COVID-19 pandemic had a mixed impact on the composite materials testing market. The initial phase of the pandemic led to disruptions in supply chains and project delays due to lockdowns and restrictions. However, the market recovered as industries resumed operations, and the demand for lightweight and durable materials remained intact.

Key Industry Developments

Many testing companies have formed strategic partnerships and collaborations with composite material manufacturers and end-users to offer comprehensive testing services and cater to specific industry needs.

Key players in the market have been acquiring smaller testing companies to expand their service offerings and geographical reach, enabling them to serve a broader customer base.

Analyst Suggestions

Companies should focus on investing in research and development to improve testing methods and keep pace with technological advancements.

Stakeholders should advocate for the development of standardized testing procedures and regulations to streamline the testing process and ensure consistency across industries.

Testing companies should explore opportunities in emerging economies to capitalize on the growing demand for composite materials in various applications.

Future Outlook

The composite materials testing market is expected to witness continued growth in the coming years. The increasing adoption of composite materials in industries like aerospace, automotive, and wind energy, coupled with advancements in testing technology, will be the primary drivers of the market. However, the industry must address challenges related to high initial investment costs and the lack of standardized testing procedures to unlock its full potential.

Conclusion

The composite materials testing market has emerged as a crucial segment of the materials testing industry, driven by the growing demand for lightweight, high-strength, and durable materials. The aerospace, automotive, construction, and wind energy sectors are among the key end-users of composite materials, making testing services essential to ensure their safety and performance. While challenges exist, such as high costs and regulatory variations, the market’s future remains promising, with opportunities in emerging economies and advancements in testing technology. Continuous investment in research and development, along with collaboration among industry stakeholders, will be pivotal in shaping the future of the composite materials testing market.

What is Composite Materials Testing?

Composite Materials Testing refers to the evaluation and analysis of composite materials to determine their mechanical, thermal, and chemical properties. This testing is crucial for applications in aerospace, automotive, and construction industries, ensuring materials meet required standards and performance criteria.

What are the key players in the Composite Materials Testing market?

Key players in the Composite Materials Testing market include Intertek Group plc, SGS SA, and Element Materials Technology, among others. These companies provide a range of testing services to ensure the quality and safety of composite materials used in various applications.

What are the growth factors driving the Composite Materials Testing market?

The growth of the Composite Materials Testing market is driven by the increasing demand for lightweight and high-strength materials in industries such as aerospace and automotive. Additionally, advancements in testing technologies and stringent regulatory standards are contributing to market expansion.

What challenges does the Composite Materials Testing market face?

The Composite Materials Testing market faces challenges such as the high costs associated with advanced testing methods and the complexity of composite materials. Furthermore, the need for specialized expertise and equipment can limit accessibility for smaller companies.

What opportunities exist in the Composite Materials Testing market?

Opportunities in the Composite Materials Testing market include the growing adoption of composites in renewable energy sectors, such as wind and solar power. Additionally, the rise of innovative testing methods, like non-destructive testing, presents new avenues for growth.

What trends are shaping the Composite Materials Testing market?

Trends in the Composite Materials Testing market include the increasing integration of automation and digital technologies in testing processes. Moreover, there is a rising focus on sustainability, leading to the development of eco-friendly composite materials and testing methods.

Composite Materials Testing market

| Segmentation Details | Description |

|---|---|

| Product Type | Thermosetting, Thermoplastic, Metal Matrix, Ceramic Matrix |

| Application | Aerospace, Automotive OEMs, Construction, Marine |

| End User | Manufacturers, Research Institutions, Government Agencies, Contractors |

| Testing Method | Mechanical Testing, Thermal Analysis, Chemical Analysis, Non-Destructive Testing |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Composite Materials Testing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at