444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

Metal fabrication equipment refers to the machinery and tools used in the manufacturing and shaping of metal products. The Benelux region, consisting of Belgium, the Netherlands, and Luxembourg, has witnessed significant growth in the metal fabrication equipment market in recent years. This market encompasses various equipment such as cutting machines, bending machines, welding machines, and others, which are essential for metal fabrication processes.

Meaning

Metal fabrication equipment plays a crucial role in the metalworking industry, enabling the efficient and precise production of metal components and structures. These machines are used across various sectors, including automotive, aerospace, construction, and machinery manufacturing, among others. The Benelux metal fabrication equipment market refers specifically to the demand, supply, and overall business environment related to such equipment in the region.

Executive Summary

The Benelux metal fabrication equipment market has experienced steady growth in recent years due to the increasing demand for metal products and the expanding manufacturing sector. Key market players have been focusing on technological advancements, product innovation, and strategic partnerships to gain a competitive edge in the market. The market offers substantial opportunities for industry participants, driven by the rising need for customized metal products and the adoption of automation in metal fabrication processes.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Benelux metal fabrication equipment market is driven by a combination of factors, including increasing demand for metal products, technological advancements, and government initiatives. The market dynamics are influenced by the interplay between market drivers, restraints, and opportunities.

Rising demand for customized metal products and the adoption of automation are major market drivers. The growth of the manufacturing sector and favorable government initiatives also contribute to market expansion. However, challenges such as high initial investment, a shortage of skilled labor, and volatile raw material prices act as restraints.

To capitalize on the market opportunities, industry participants need to focus on developing lightweight materials, catering to the renewable energy sector, embracing additive manufacturing, and aligning with the principles of Industry 4.0. A thorough understanding of the market dynamics is crucial for companies to make informed decisions and maintain a competitive edge.

Regional Analysis

The Benelux metal fabrication equipment market can be analyzed at the country level, considering Belgium, the Netherlands, and Luxembourg individually. Each country has its unique characteristics and market dynamics within the region.

Understanding the specific market dynamics and trends in each country within the Benelux region is crucial for market players to tailor their strategies and capitalize on the regional opportunities.

Competitive Landscape

Leading Companies in the Benelux Metal Fabrication Equipment Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

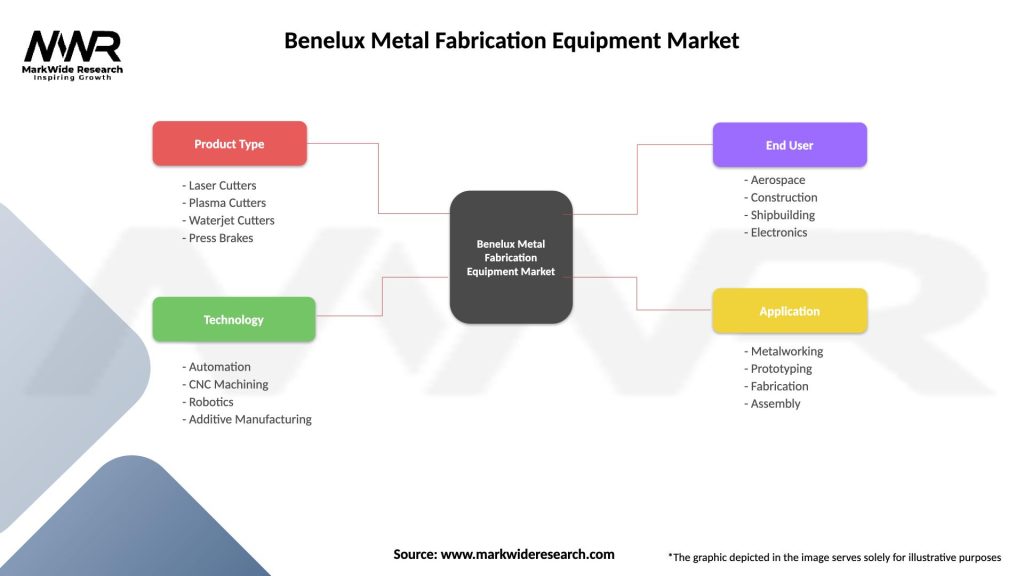

Segmentation

The Benelux metal fabrication equipment market can be segmented based on various factors, including equipment type, end-use industry, and technology.

Segmentation allows market players to identify specific market segments and target their products and services accordingly. Understanding the unique requirements and preferences of each segment enables companies to optimize their offerings and gain a competitive edge.

Category-wise Insights

Understanding the specific characteristics and applications of each category of metal fabrication equipment enables industry participants to align their product offerings with customer requirements and market trends.

Key Benefits for Industry Participants and Stakeholders

The Benelux metal fabrication equipment market offers several benefits for industry participants and stakeholders:

Industry participants and stakeholders can leverage these benefits to strengthen their market position, attract customers, and achieve sustainable growth in the Benelux metal fabrication equipment market.

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis provides an overview of the internal and external factors influencing a company’s performance in the market.

By identifying strengths, weaknesses, opportunities, and threats, companies can develop strategies to capitalize on their strengths, address weaknesses, seize opportunities, and mitigate potential threats.

Market Key Trends

Understanding these key trends helps industry participants stay ahead of the curve, anticipate market demands, and align their strategies with evolving customer preferences.

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the Benelux metal fabrication equipment market. The outbreak disrupted global supply chains, leading to material shortages and delays in equipment deliveries. Manufacturing activities faced temporary shutdowns and reduced demand, impacting the market’s growth.

However, the pandemic also highlighted the importance of resilient and flexible manufacturing processes. The crisis accelerated the adoption of automation and robotics to ensure business continuity and reduce dependency on manual labor. Manufacturers increasingly focused on improving operational efficiencyand implementing remote monitoring and control systems.

The pandemic also highlighted the need for agile manufacturing and quick adaptation to changing market demands. Companies that were able to pivot their production capabilities to essential products, such as medical equipment or components for critical infrastructure, fared better during the crisis.

Moreover, the pandemic emphasized the significance of digitalization and remote collaboration. Virtual meetings, remote training, and digital platforms became essential for communication and knowledge sharing. This trend is likely to continue even after the pandemic, as companies recognize the benefits of remote capabilities and digital tools.

Overall, the Covid-19 pandemic has accelerated the adoption of automation, digitalization, and agile manufacturing practices in the Benelux metal fabrication equipment market. Companies that have embraced these changes are better positioned to navigate future uncertainties and drive growth.

Key Industry Developments

These key industry developments indicate a dynamic and evolving market landscape, with a focus on technological advancements, partnerships, and sustainability.

Analyst Suggestions

Based on the market analysis, here are some suggestions for industry participants:

By implementing these suggestions, industry participants can position themselves for growth, profitability, and long-term success in the Benelux metal fabrication equipment market.

Future Outlook

The future outlook for the Benelux metal fabrication equipment market is positive, driven by various factors such as increasing demand for metal products, technological advancements, and the shift toward sustainable manufacturing practices.

The demand for customized metal components and structures is expected to continue growing across industries such as automotive, aerospace, and construction. Manufacturers will need advanced metal fabrication equipment to meet the rising demand for unique designs, improved performance, and quick turnaround times.

Technological advancements will play a crucial role in shaping the market’s future. Integration of IoT, AI, and robotics will further enhance equipment capabilities, leading to increased productivity, improved accuracy, and reduced production time.

The adoption of additive manufacturing technologies will continue to expand, enabling the production of complex metal parts with enhanced design freedom and reduced material waste. Metal 3D printing is expected to revolutionize the metal fabrication industry by providing efficient and cost-effective manufacturing solutions.

Sustainability will remain a key focus area. Manufacturers will continue to implement eco-friendly practices, energy-efficient equipment, and waste reduction strategies. Compliance with environmental regulations and meeting customer demands for sustainable products will drive innovation and market growth.

The Covid-19 pandemic has accelerated the adoption of digitalization, automation, and remote capabilities. These trends will continue to shape the future of the metal fabrication equipment market, enabling manufacturers to adapt to changing market conditions, improve operational efficiency, and enhance customer experiences.

Conclusion

The Benelux metal fabrication equipment market offers immense potential for growth and innovation. The demand for customized metal products, the adoption of automation and robotics, and technological advancements are driving the market forward. However, challenges such as high initial investment, a shortage of skilled labor, and volatile raw material prices need to be addressed.

Industry participants can leverage market opportunities by focusing on lightweight materials, catering to the renewable energy sector, embracing additive manufacturing, and adopting Industry 4.0 principles. Understanding market dynamics, customer preferences, and emerging trends will be crucial for companies to maintain a competitive edge. Collaborations, strategic partnerships, and mergers and acquisitions will facilitate technological advancements, expand product portfolios, and enter new markets. Sustainable practices and compliance with environmental regulations will also play a vital role in shaping the market’s future.

What is Metal Fabrication Equipment?

Metal Fabrication Equipment refers to the machinery and tools used in the process of shaping and assembling metal structures. This includes equipment such as laser cutters, welding machines, and bending tools, which are essential in various industries including construction, automotive, and aerospace.

What are the key players in the Benelux Metal Fabrication Equipment Market?

Key players in the Benelux Metal Fabrication Equipment Market include Trumpf, Amada, and Bystronic, which are known for their advanced technologies and innovative solutions in metal fabrication. These companies provide a range of equipment and services that cater to diverse industrial needs, among others.

What are the growth factors driving the Benelux Metal Fabrication Equipment Market?

The growth of the Benelux Metal Fabrication Equipment Market is driven by increasing demand for customized metal products, advancements in automation technology, and the expansion of the automotive and construction sectors. Additionally, the push for lightweight materials in manufacturing is also contributing to market growth.

What challenges does the Benelux Metal Fabrication Equipment Market face?

Challenges in the Benelux Metal Fabrication Equipment Market include high initial investment costs, the need for skilled labor, and competition from low-cost manufacturers. These factors can hinder the growth and adoption of advanced metal fabrication technologies.

What opportunities exist in the Benelux Metal Fabrication Equipment Market?

Opportunities in the Benelux Metal Fabrication Equipment Market include the increasing adoption of Industry Four Point Zero technologies, the rise of sustainable manufacturing practices, and the growing demand for precision engineering. These trends are likely to create new avenues for innovation and investment.

What trends are shaping the Benelux Metal Fabrication Equipment Market?

Trends shaping the Benelux Metal Fabrication Equipment Market include the integration of smart technologies, such as IoT and AI, into fabrication processes, as well as a shift towards more sustainable practices. Additionally, there is a growing emphasis on automation and robotics to enhance efficiency and reduce labor costs.

Benelux Metal Fabrication Equipment Market

| Segmentation Details | Description |

|---|---|

| Product Type | Laser Cutters, Plasma Cutters, Waterjet Cutters, Press Brakes |

| Technology | Automation, CNC Machining, Robotics, Additive Manufacturing |

| End User | Aerospace, Construction, Shipbuilding, Electronics |

| Application | Metalworking, Prototyping, Fabrication, Assembly |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Benelux Metal Fabrication Equipment Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at