444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The Asia-Pacific industrial valves market refers to the industry dedicated to the manufacturing, distribution, and sales of various types of valves used in industrial applications across the Asia-Pacific region. Valves play a crucial role in controlling the flow of liquids, gases, and other substances in different industrial processes. These valves are widely used in industries such as oil and gas, power generation, water and wastewater treatment, chemical processing, pharmaceuticals, and many others.

Meaning

Industrial valves are mechanical devices designed to regulate, control, or direct the flow of fluids (liquids, gases, or slurries) through a pipe or passage. They are commonly used in industries to control the pressure, temperature, and flow rate of fluids in various processes. Valves come in different types, including gate valves, ball valves, butterfly valves, check valves, globe valves, and plug valves, among others. Each type of valve has its unique characteristics and applications.

Executive Summary

The Asia-Pacific industrial valves market has experienced significant growth in recent years. The region’s rapid industrialization, expanding infrastructure development, and increasing demand for energy and water management have been the key factors driving the market growth. Additionally, the focus on process optimization, improved safety standards, and environmental regulations has further fueled the demand for advanced and reliable industrial valves in the Asia-Pacific region.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Several key market insights highlight the Asia-Pacific industrial valves market. Firstly, the market is witnessing a surge in demand due to the growing need for energy and water management infrastructure across the region. Secondly, advancements in technology, such as the integration of Internet of Things (IoT) and automation, are transforming the industrial valves industry. These advancements enable remote monitoring, predictive maintenance, and enhanced operational efficiency. Lastly, the market is highly competitive, with both local and international players vying for market share by offering innovative products and solutions.

Market Drivers

The Asia-Pacific industrial valves market is driven by various factors. One of the primary drivers is the increasing demand for energy and water management infrastructure. The region’s rapid urbanization, population growth, and industrial expansion have led to a surge in energy consumption and water demand. This, in turn, has propelled the need for reliable and efficient valves to control the flow of fluids in power generation plants, oil and gas refineries, water treatment facilities, and other industrial applications.

Furthermore, stringent safety regulations and the need to minimize environmental impact have driven the adoption of advanced valves. Industrial valves equipped with advanced features such as leak detection, fail-safe mechanisms, and reduced emissions help industries comply with safety and environmental standards.

Market Restraints

Despite the positive market outlook, the Asia-Pacific industrial valves market faces certain challenges. One of the key restraints is the high initial investment required for the installation of industrial valves. The cost associated with purchasing, installing, and maintaining valves can be significant, especially for small and medium-sized enterprises. Additionally, the market faces challenges related to the availability of skilled labor and the need for regular maintenance and servicing of valves to ensure optimal performance.

Market Opportunities

The Asia-Pacific industrial valves market presents several opportunities for growth and expansion. The increasing focus on renewable energy sources, such as solar and wind power, opens up new avenues for valve manufacturers. These industries require specialized valves designed to handle unique operating conditions and ensure efficient energy generation.

Moreover, the adoption of smart technologies and automation presents opportunities for valve manufacturers to develop intelligent valves that can be remotely monitored and controlled. This integration of IoT and automation technologies enables real-time data analysis, predictive maintenance, and improved operational efficiency.

Market Dynamics

The Asia-Pacific industrial valves market is characterized by dynamic factors that shape its growth and development. The market dynamics are influenced by factors such as technological advancements, regulatory policies, economic conditions, and industry trends. Manufacturers in the region continually strive to innovate and offer superior products to gain a competitive edge. Additionally, collaborations, mergers, and acquisitions are common strategies employed by key market players to expand their product portfolio and geographic presence.

Regional Analysis

The Asia-Pacific industrial valves market can be analyzed based on various regions within the Asia-Pacific region, including East Asia, Southeast Asia, South Asia, and Oceania. Each region has its unique market characteristics, influenced by factors such as economic growth, industrial development, infrastructure investments, and government policies. East Asia, including countries like China, Japan, and South Korea, is a major market for industrial valves, driven by its large manufacturing and energy sectors. Southeast Asia is witnessing significant growth due to infrastructure development and increasing industrial activities. South Asia and Oceania also offer substantial market potential, driven by infrastructure investments and the growing demand for energy and water management solutions.

Competitive Landscape

Leading Companies in the Asia-Pacific Industrial Valves Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

By Valve Type

By End-User Industry

By Region

Category-wise Insights

The Asia-Pacific industrial valves market offers category-wise insights into different aspects of the market. For example, in terms of valve type, ball valves have witnessed significant growth due to their versatility, reliability, and ease of operation. The oil and gas industry has been a major end-user, driving the demand for industrial valves in the region. Water and wastewater treatment is another key sector that requires a wide range of valves for various processes, including filtration, disinfection, and distribution.

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders in the Asia-Pacific industrial valves market can benefit in several ways. Firstly, the market offers opportunities for revenue generation and business expansion, driven by the region’s industrial growth and infrastructure development. The demand for advanced valves opens up avenues for manufacturers, distributors, and suppliers to cater to the specific needs of different industries. Additionally, advancements in technology and the integration of smart features in valves enable improved operational efficiency, cost savings, and reduced environmental impact, providing benefits to both industry participants and the end-users.

SWOT Analysis

Strengths

Weaknesses

Opportunities

Threats

Market Key Trends

The Asia-Pacific industrial valves market exhibits several key trends that are shaping its growth and development. Firstly, the integration of IoT and automation technologies has revolutionized the industry by enabling remote monitoring, predictive maintenance, and enhanced operational efficiency. Secondly, the market is witnessing a shift towards the use of sustainable materials and eco-friendly manufacturing processes to reduceenvironmental impact. This trend aligns with the growing emphasis on sustainability and green practices across industries.

Another key trend is the adoption of digitalization and data analytics in valve operations. Industrial valves equipped with sensors and data collection capabilities enable real-time monitoring, performance analysis, and predictive maintenance, leading to improved efficiency and reduced downtime.

Furthermore, there is a rising demand for customized and specialized valves to meet the specific requirements of different industries. Manufacturers are focusing on developing valves that can withstand extreme conditions, such as high temperatures and corrosive environments, while ensuring optimal performance and reliability.

Covid-19 Impact

The Covid-19 pandemic has had a significant impact on the Asia-Pacific industrial valves market. The outbreak led to disruptions in global supply chains, temporary shutdowns of manufacturing facilities, and a decline in industrial activities. As a result, the demand for industrial valves experienced a slowdown during the initial phase of the pandemic.

However, as economies gradually reopened and industries resumed operations, the demand for industrial valves began to recover. The need for essential services such as power generation, water treatment, and pharmaceutical production remained strong, driving the demand for valves in these sectors. Additionally, the focus on health and safety measures in industries led to increased investments in valve technologies that ensure hygiene, cleanliness, and contactless operations.

Key Industry Developments

The Asia-Pacific industrial valves market has witnessed several key industry developments in recent years. Market players have been actively engaged in product development, innovation, and expansion strategies to strengthen their market presence. Some notable developments include:

Analyst Suggestions

Based on the analysis of the Asia-Pacific industrial valves market, analysts suggest several strategies for industry participants:

Future Outlook

The future outlook for the Asia-Pacific industrial valves market is optimistic. The region’s continuous industrial growth, infrastructure development, and increasing focus on energy and water management will drive the demand for industrial valves. Technological advancements, including smart valves and digitalization, will further enhance the market’s growth potential. Additionally, the rising adoption of renewable energy sources and the need for sustainable solutions will create new opportunities for valve manufacturers.

However, the market is expected to face challenges such as intense competition, price volatility of raw materials, and stringent regulatory requirements. Manufacturers need to stay agile, innovative, and responsive to changing market dynamics to sustain growth and maintain a competitive position.

Conclusion

The Asia-Pacific industrial valves market is witnessing robust growth driven by the region’s industrialization, infrastructure development, and increasing demand for energy and water management solutions. The market offers significant opportunities for manufacturers, distributors, and suppliers to cater to diverse industry requirements.

Technological advancements, integration of smart features, and a focus on sustainability are key trends shaping the market. The Covid-19 pandemic has had a temporary impact, but the market has shown resilience and recovery.

To succeed in this competitive landscape, industry participants should embrace technological advancements, adopt a customer-centric approach, expand into emerging markets, and prioritize sustainable practices. The future outlook for the Asia-Pacific industrial valves market is positive, with continued growth expected as industries evolve and demand for advanced valve solutions increases.

What is Industrial Valves?

Industrial valves are mechanical devices used to control the flow of fluids in various applications, including water supply, oil and gas, and chemical processing. They play a crucial role in regulating pressure, flow rate, and direction within pipelines and systems.

What are the key players in the Asia-Pacific Industrial Valves Market?

Key players in the Asia-Pacific Industrial Valves Market include Emerson Electric Co., Flowserve Corporation, and Kitz Corporation, among others. These companies are known for their innovative valve solutions and extensive product portfolios catering to various industries.

What are the growth factors driving the Asia-Pacific Industrial Valves Market?

The Asia-Pacific Industrial Valves Market is driven by increasing industrialization, the expansion of the oil and gas sector, and the rising demand for water and wastewater management solutions. Additionally, advancements in automation and smart valve technologies are contributing to market growth.

What challenges does the Asia-Pacific Industrial Valves Market face?

Challenges in the Asia-Pacific Industrial Valves Market include fluctuating raw material prices, stringent regulatory standards, and the need for regular maintenance and replacement of valves. These factors can impact operational efficiency and increase costs for manufacturers.

What opportunities exist in the Asia-Pacific Industrial Valves Market?

Opportunities in the Asia-Pacific Industrial Valves Market include the growing focus on sustainable energy solutions, the development of smart and automated valve systems, and the increasing investments in infrastructure projects. These trends are expected to enhance market potential in the coming years.

What trends are shaping the Asia-Pacific Industrial Valves Market?

Current trends in the Asia-Pacific Industrial Valves Market include the integration of IoT technology for real-time monitoring, the shift towards eco-friendly materials, and the rise of digitalization in manufacturing processes. These trends are influencing product development and customer preferences.

Asia-Pacific Industrial Valves Market

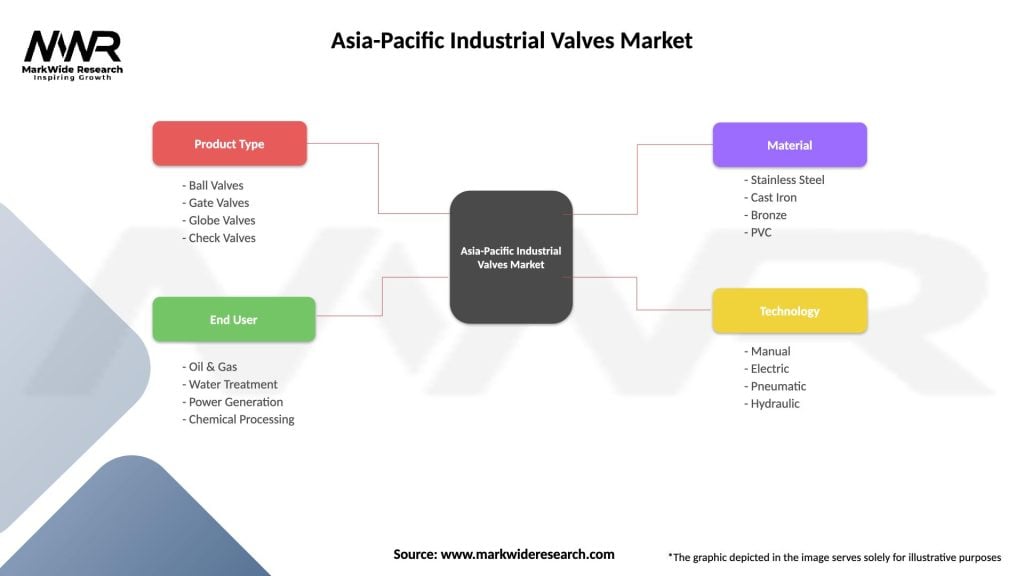

| Segmentation Details | Description |

|---|---|

| Product Type | Ball Valves, Gate Valves, Globe Valves, Check Valves |

| End User | Oil & Gas, Water Treatment, Power Generation, Chemical Processing |

| Material | Stainless Steel, Cast Iron, Bronze, PVC |

| Technology | Manual, Electric, Pneumatic, Hydraulic |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Asia-Pacific Industrial Valves Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at