444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The 3D-printed prosthetic implants market has witnessed substantial growth in recent years, driven by advancements in 3D printing technology and the increasing demand for customized and patient-specific implants. This innovative approach to manufacturing prosthetics offers numerous benefits, including improved fit, functionality, and patient satisfaction. The market is characterized by a dynamic landscape with several key players competing to gain a significant share in the industry.

Meaning

3D-printed prosthetic implants refer to the artificial limbs or body parts that are created using additive manufacturing techniques. Unlike traditional prosthetics, which are often mass-produced and may not perfectly match the individual’s unique anatomy, 3D-printed implants are customized to fit the patient’s specific requirements. This personalized approach ensures better comfort, mobility, and overall quality of life for individuals in need of prosthetic replacements.

Executive Summary

The 3D-printed prosthetic implants market is experiencing rapid growth globally. The increasing prevalence of disabilities and injuries requiring prosthetic interventions, coupled with advancements in 3D printing technology, has fueled the demand for personalized and high-quality prosthetic implants. This executive summary provides an overview of the market, highlighting the key insights, drivers, restraints, opportunities, and trends shaping the industry. Additionally, it offers valuable recommendations for industry participants and stakeholders, along with a future outlook for the market.

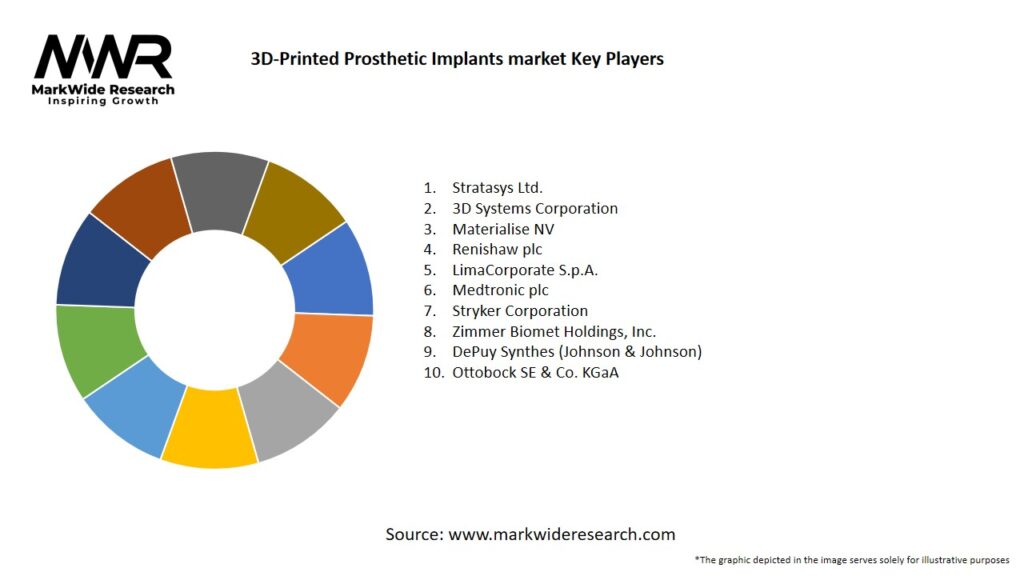

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The 3D-printed prosthetic implants market is propelled by several key drivers:

Market Restraints

While the market shows significant potential, several factors restrain its growth:

Market Opportunities

The 3D-printed prosthetic implants market presents several opportunities for growth and innovation:

Market Dynamics

The 3D-printed prosthetic implants market is characterized by dynamic factors that influence its growth trajectory:

Regional Analysis

The 3D-printed prosthetic implants market exhibits regional variations in terms of market size, growth potential, and adoption rates. The key regions analyzed in this report include North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

Competitive Landscape

Leading Companies in the 3D-Printed Prosthetic Implants Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

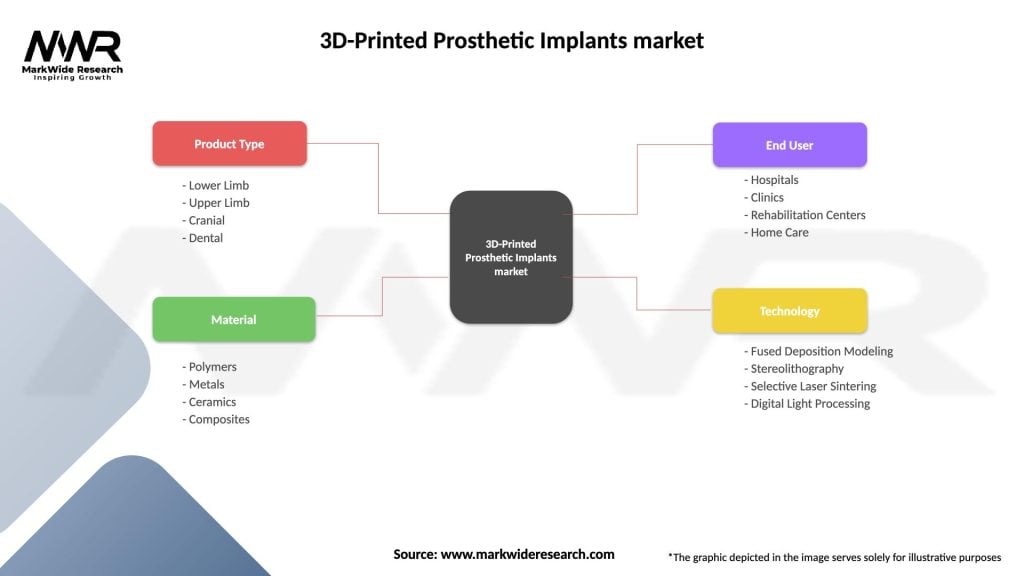

Segmentation

The 3D-printed prosthetic implants market can be segmented based on the following factors:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders in the 3D-printed prosthetic implants market can benefit in the following ways:

SWOT Analysis

The SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis of the 3D-printed prosthetic implants market provides valuable insights into the market’s internal and external factors:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has had both positive and negative impacts on the 3D-printed prosthetic implants market:

Positive Impact:

Negative Impact:

Despite the temporary setbacks, the market is expected to recover and continue its growth trajectory in the post-pandemic period.

Key Industry Developments

Analyst Suggestions

Based on the analysis of the 3D-printed prosthetic implants market, analysts suggest the following:

Future Outlook

The future of the 3D-printed prosthetic implants market looks promising, with opportunities for growth and technological advancements. The market is expected to witness continued expansion driven by factors such as increasing demand for personalized and patient-specific prosthetic solutions, advancements in 3D printing technology, and expanding applications across various medical specialties.

Industry players are likely to focus on developing cost-effective 3D printing solutions, collaborating with healthcare providers, and investing in R&D to enhance the functionality, biocompatibility, and overall quality of prosthetic implants. As regulations evolve and reimbursement policies become more favorable, the adoption of 3D-printed prosthetic implants is expected to increase, improving the quality of life for individuals in need of prosthetic interventions.

Conclusion

The 3D-printed prosthetic implants market is experiencing rapid growth and technological advancements. The ability to create customized and patient-specific prosthetic solutions offers numerous benefits, including improved comfort, fit, and overall patient satisfaction. While the market is driven by factors such as technological advancements, increasing demand for personalized healthcare, and favorable reimbursement policies, it also faces challenges such as high costs and regulatory complexities.

Industry participants and stakeholders should focus on innovation, collaborations, and education to drive market growth and ensure the widespread adoption of 3D-printed prosthetic implants. As the market continues to evolve, it holds great potential to transform the lives of individuals in need of prosthetic interventions, providing them with improved mobility, functionality, and quality of life.

What is 3D-Printed Prosthetic Implants?

3D-Printed Prosthetic Implants refer to custom-made prosthetic devices created using additive manufacturing technology. These implants are designed to fit the unique anatomy of individual patients, enhancing comfort and functionality compared to traditional prosthetics.

What are the key players in the 3D-Printed Prosthetic Implants market?

Key players in the 3D-Printed Prosthetic Implants market include companies like Össur, Materialise, and Stratasys, which are known for their innovative approaches to prosthetic design and manufacturing. These companies focus on improving patient outcomes through advanced technology and customization, among others.

What are the growth factors driving the 3D-Printed Prosthetic Implants market?

The growth of the 3D-Printed Prosthetic Implants market is driven by factors such as the increasing prevalence of limb loss, advancements in 3D printing technology, and the rising demand for personalized medical solutions. Additionally, the cost-effectiveness of 3D printing contributes to its adoption in healthcare.

What challenges does the 3D-Printed Prosthetic Implants market face?

The 3D-Printed Prosthetic Implants market faces challenges such as regulatory hurdles, the need for skilled professionals to operate advanced printing technologies, and concerns regarding material durability and biocompatibility. These factors can impact the widespread adoption of 3D-printed solutions.

What opportunities exist in the 3D-Printed Prosthetic Implants market?

Opportunities in the 3D-Printed Prosthetic Implants market include the potential for innovations in biocompatible materials, the expansion of telemedicine for remote fittings, and collaborations between technology firms and healthcare providers. These developments can enhance accessibility and patient care.

What trends are shaping the 3D-Printed Prosthetic Implants market?

Trends in the 3D-Printed Prosthetic Implants market include the integration of artificial intelligence for design optimization, the use of lightweight materials for improved mobility, and the growing emphasis on patient-centered design. These trends are transforming how prosthetics are developed and utilized.

3D-Printed Prosthetic Implants market

| Segmentation Details | Description |

|---|---|

| Product Type | Lower Limb, Upper Limb, Cranial, Dental |

| Material | Polymers, Metals, Ceramics, Composites |

| End User | Hospitals, Clinics, Rehabilitation Centers, Home Care |

| Technology | Fused Deposition Modeling, Stereolithography, Selective Laser Sintering, Digital Light Processing |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the 3D-Printed Prosthetic Implants Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at