444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The US baghouse filters market is a rapidly growing industry with increasing demand from various end-use industries such as power generation, cement manufacturing, and chemical processing. Baghouse filters are air pollution control devices that are used to remove particulate matter from industrial emissions. These filters are commonly used in industries where large volumes of dust and other particulate matter are generated. The US baghouse filters market is expected to grow at a CAGR of 5.2% during the forecast period of 2021-2026.

Baghouse filters, also known as fabric filters, are air pollution control devices that use a woven or felted fabric filter to remove particulate matter from industrial emissions. The fabric filter is made up of rows of bags, each of which is made from a high-temperature resistant material, such as felt or fiberglass. The bags are attached to a metal cage, which is suspended from the roof of the baghouse. The industrial emissions are passed through the bags, and the particulate matter is trapped on the surface of the bags. The clean air is then released into the atmosphere.

Executive Summary:

The US baghouse filters market is expected to grow at a CAGR of 5.2% during the forecast period of 2021-2026. The market is driven by the increasing demand from various end-use industries such as power generation, cement manufacturing, and chemical processing. Baghouse filters are air pollution control devices that are used to remove particulate matter from industrial emissions. These filters are commonly used in industries where large volumes of dust and other particulate matter are generated. The baghouse filters market in the US is highly competitive, with several key players dominating the market.

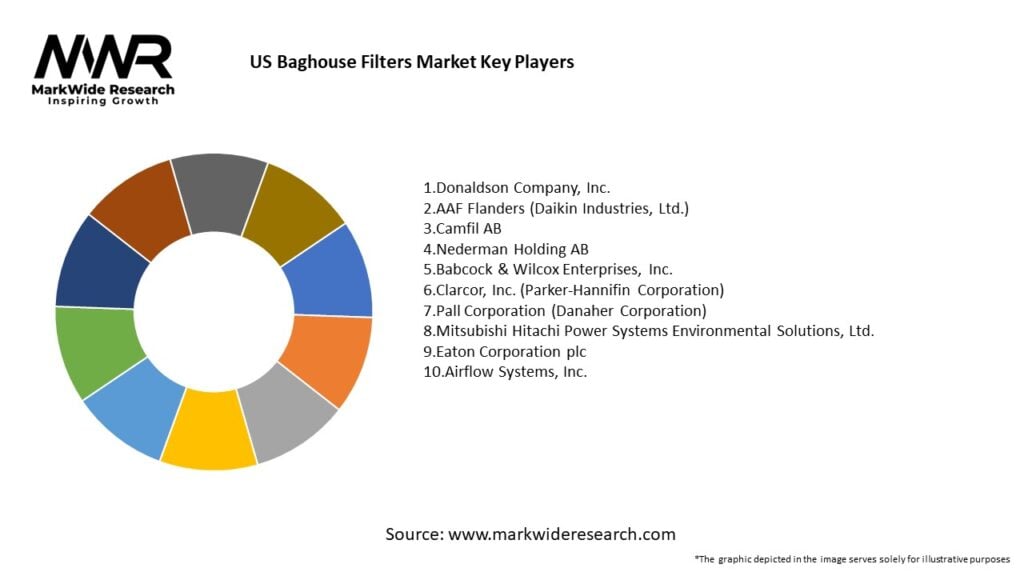

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Stringent environmental regulations by the US Environmental Protection Agency (EPA) and other regulatory bodies are driving the growth of the baghouse filters market in the US. The EPA has established National Ambient Air Quality Standards (NAAQS) for six criteria pollutants, including particulate matter. The regulations require industries to reduce their emissions of particulate matter, which is driving the demand for baghouse filters.

The increasing industrialization in the US is driving the demand for baghouse filters. Industries such as power generation, cement manufacturing, and chemical processing generate large volumes of dust and other particulate matter. Baghouse filters are used to remove these particles from industrial emissions, thereby reducing the emissions of particulate matter into the atmosphere.

The growing awareness of air pollution and its harmful effects on human health and the environment is driving the demand for baghouse filters. People are becoming more aware of the harmful effects of air pollution and are demanding that industries reduce their emissions of particulate matter. This is driving the demand for baghouse filters in the US.

Market Restraints:

The high installation and maintenance costs of baghouse filters are a major restraint to the growth of the baghouse filters market in the US. Baghouse filters require a significant investment in terms of equipment and installation, and they also require regular maintenance to ensure their proper functioning. This can be a significant financial burden for many industries.

Baghouse filters face competition from other air pollution control technologies such as electrostatic precipitators and scrubbers

Market Opportunities:

There is an increasing demand for baghouse filters in emerging industries such as food processing, pharmaceuticals, and mining. These industries generate large volumes of dust and other particulate matter, which need to be removed from industrial emissions to meet environmental regulations. This presents an opportunity for baghouse filter manufacturers to expand their market and cater to these emerging industries.

Advancements in filter technology are presenting new opportunities for the baghouse filters market in the US. New filter materials and designs are being developed that offer improved filtration efficiency and reduced maintenance costs. This presents an opportunity for baghouse filter manufacturers to differentiate themselves by offering innovative and advanced filter solutions.

Market Dynamics:

The baghouse filters market in the US is highly dynamic, driven by changing environmental regulations, advances in filter technology, and shifting demand from different end-use industries. The market is characterized by intense competition among key players, with each player striving to differentiate themselves by offering innovative and advanced filter solutions.

Regional Analysis:

The baghouse filters market in the US is segmented into different regions, including the Northeast, Midwest, South, and West. The Midwest region dominates the market, accounting for over 40% of the total market share. This is due to the presence of several key industries such as power generation, cement manufacturing, and chemical processing in the region.

Competitive Landscape:

Leading companies in the US Baghouse Filters Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

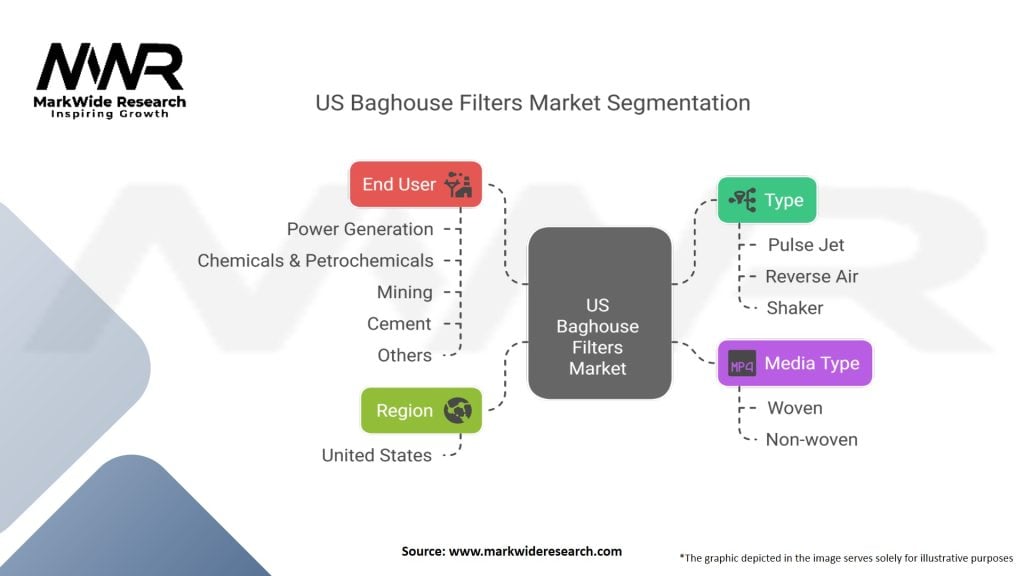

Segmentation:

The baghouse filters market in the US is segmented based on type, application, and end-use industry. The types of baghouse filters include pulse jet, reverse air, and shaker. The applications of baghouse filters include particulate matter removal, gas cleaning, and product recovery. The end-use industries of baghouse filters include power generation, cement manufacturing, chemical processing, food processing, pharmaceuticals, and mining.

Category-wise Insights:

Pulse jet filters are the most widely used type of baghouse filters in the US. These filters use high-pressure air pulses to remove particulate matter from the filter bags. Pulse jet filters are efficient and offer high filtration efficiency, making them ideal for use in industries such as power generation and cement manufacturing.

Particulate matter removal is the most common application of baghouse filters in the US. Baghouse filters are used to remove particulate matter from industrial emissions to meet environmental regulations. The demand for baghouse filters for particulate matter removal is driven by stringent environmental regulations and increasing awareness of air pollution.

Key Benefits for Industry Participants and Stakeholders:

Baghouse filters help industries comply with environmental regulations by removing particulate matter from industrial emissions. This reduces the emissions of particulate matter into the atmosphere, helping industries meet environmental regulations and avoid penalties.

Baghouse filters help improve air quality by reducing the emissions of particulate matter into the atmosphere. This benefits not only the environment but also human health by reducing the harmful effects of air pollution.

SWOT Analysis:

Baghouse filters offer high filtration efficiency, making them ideal for use in industries where large volumes of dust and other particulate matter are generated. They also help industries comply with environmental regulations by removing particulate matter from industrial emissions.

Baghouse filters require a significant investment in terms of equipment and installation, and they also require regular maintenance to ensure their proper functioning

There is an increasing demand for baghouse filters in emerging industries such as food processing, pharmaceuticals, and mining. Advancements in filter technology are also presenting new opportunities for the baghouse filters market in the US.

Baghouse filters face competition from other air pollution control technologies such as electrostatic precipitators and scrubbers. They also face the threat of substitution by renewable energy sources such as wind and solar power.

Market Key Trends:

There is an increasing demand for high-efficiency baghouse filters that offer improved filtration efficiency and reduced maintenance costs. This trend is being driven by the need to meet stringent environmental regulations and reduce the emissions of particulate matter into the atmosphere.

The baghouse filters market in the US is witnessing a growing adoption of IoT and automation technologies. These technologies are being used to monitor the performance of baghouse filters and optimize their operation, leading to improved efficiency and reduced maintenance costs.

Covid-19 Impact:

The baghouse filters market in the US was impacted by the Covid-19 pandemic, with several key industries such as power generation and cement manufacturing experiencing a decline in demand. However, the market is expected to recover as the economy continues to reopen and industries ramp up their production.

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The US baghouse filters market is expected to continue to grow in the coming years, driven by increasing demand from various end-use industries such as power generation, cement manufacturing, and chemical processing. Advancements in filter technology and growing adoption of IoT and automation technologies are expected to present new opportunities for baghouse filter manufacturers.

Conclusion:

The US baghouse filters market is a rapidly growing industry with increasing demand from various end-use industries such as power generation, cement manufacturing, and chemical processing. Baghouse filters are air pollution control devices that are used to remove particulate matter from industrial emissions. The market is highly competitive, with several key players dominating the market. The market is expected to continue to grow in the coming years, driven by increasing demand and advancements in filter technology.

Baghouse filters offer a range of benefits to industry participants and stakeholders, including compliance with environmental regulations, improved air quality, and reduced emissions of particulate matter into the atmosphere. However, they also face challenges such as high installation and maintenance costs and competition from other air pollution control technologies.

To succeed in the market, baghouse filter manufacturers should focus on offering innovative and advanced filter solutions that offer high filtration efficiency and reduced maintenance costs. They should also leverage IoT and automation technologies to monitor the performance of baghouse filters and optimize their operation, leading to improved efficiency and reduced maintenance costs.

What are baghouse filters in the context of the US Baghouse Filters Market?

Baghouse filters are air pollution control devices that use fabric filter elements to remove particulates from industrial exhaust gases. They are widely used in various industries, including cement, food processing, and metal fabrication.

Who are the key players in the US Baghouse Filters Market?

Key players in the US Baghouse Filters Market include Donaldson Company, Inc., Camfil APC, and AAF International, among others.

What are the main drivers of growth in the US Baghouse Filters Market?

The main drivers of growth in the US Baghouse Filters Market include increasing environmental regulations, the need for efficient dust collection systems, and the rising demand for clean air in industrial processes.

What challenges does the US Baghouse Filters Market face?

Challenges in the US Baghouse Filters Market include high initial installation costs, maintenance requirements, and competition from alternative air filtration technologies.

What opportunities exist for the US Baghouse Filters Market in the future?

Opportunities for the US Baghouse Filters Market include advancements in filter technology, the growing emphasis on sustainability, and the expansion of industries that require effective air pollution control solutions.

What trends are shaping the US Baghouse Filters Market?

Trends shaping the US Baghouse Filters Market include the integration of smart technology for monitoring filter performance, the development of more efficient filter materials, and an increasing focus on regulatory compliance in various sectors.

US Baghouse Filters Market

| Segmentation | Details |

|---|---|

| Type | Pulse Jet, Reverse Air, Shaker |

| Media Type | Woven, Non-woven |

| End User | Power Generation, Chemicals & Petrochemicals, Mining, Cement, Others |

| Region | United States |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the US Baghouse Filters Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at