444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The hoist sling chains assemblies market is a rapidly growing industry that deals with the manufacturing and distribution of hoist chains and slings that are used for lifting and transporting heavy loads. Hoist chains and slings are widely used in industries such as construction, mining, manufacturing, and transportation.

The global hoist sling chains assemblies market is expected to grow at a CAGR of XX% during the forecast period from 2021 to 2028. The market size was estimated to be USD XX billion in 2020 and is expected to reach USD XX billion by the end of the forecast period.

Hoist sling chains assemblies are typically composed of chains or wire ropes and sling components such as hooks, shackles, and other fittings. They are used to lift and move heavy objects or materials in various industries, including manufacturing, construction, mining, and transportation.

The chains and slings used in hoist sling assemblies are typically made from materials such as steel, alloy steel, and other high-strength materials. The chains and slings are designed to withstand high loads and are rigorously tested for strength and durability.

Hoist Sling Chains Assemblies: Executive Summary

The global hoist sling chains assemblies market is expected to grow at a rapid pace during the forecast period from 2021 to 2028. The market is driven by increasing demand for hoist chains and slings in various industries, including manufacturing, construction, mining, and transportation.

The Asia-Pacific region is expected to be the fastest-growing market during the forecast period, driven by increasing demand from countries such as China, India, and Japan. North America and Europe are also expected to witness significant growth during the forecast period.

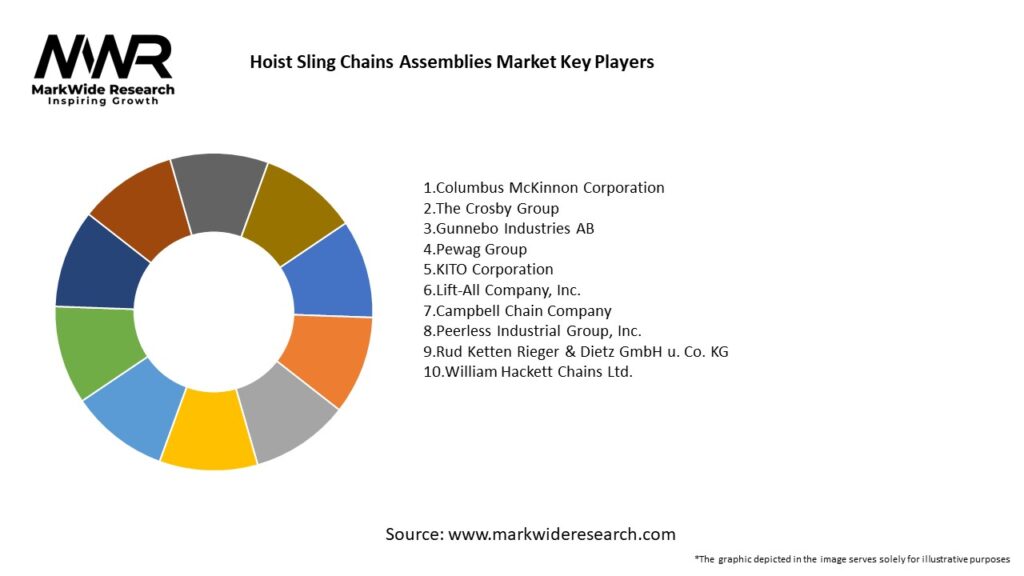

The key players in the hoist sling chains assemblies market include companies such as Columbus McKinnon Corporation, KITO Corporation, Gunnebo Industries, and Peerless Industrial Group.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Increasing Industrialization: The growing demand for material handling and lifting solutions in industries like construction, automotive, and manufacturing is fueling the demand for hoist sling chains assemblies.

Safety Standards and Regulations: Stringent safety regulations in the workplace, including those related to lifting operations, are driving the need for durable and reliable hoist sling chains to ensure compliance and reduce workplace accidents.

Technological Advancements: Innovations in chain design, materials, and corrosion resistance are enhancing the durability and functionality of hoist sling chains assemblies, making them more efficient and long-lasting.

Asia-Pacific Growth: The Asia-Pacific region, particularly China and India, is witnessing rapid industrialization, contributing to the rising demand for hoist sling chains assemblies in construction, manufacturing, and logistics sectors.

Market Drivers

Several factors are driving the growth of the Hoist Sling Chains Assemblies Market:

Growing Demand for Industrial Lifting Solutions: With industries such as construction, manufacturing, and automotive growing rapidly, there is an increasing need for hoisting and lifting equipment. Hoist sling chains assemblies play a critical role in ensuring safe and efficient lifting operations in these sectors.

Adherence to Safety Regulations: Workplace safety is a growing concern, and governments worldwide are implementing stricter regulations related to material handling and lifting. This is driving the demand for reliable hoist sling chains assemblies that meet safety standards and provide operational security.

Technological Advancements: Innovations in chain and sling designs, as well as improvements in material strength and corrosion resistance, are enhancing the performance and longevity of hoist sling chains assemblies. These advancements help industries reduce maintenance costs and improve the efficiency of lifting operations.

Infrastructure Development: Rapid infrastructure development in emerging economies, particularly in Asia-Pacific and the Middle East, is increasing the demand for hoist sling chains in construction and industrial projects.

Growing Automation in Warehouses: The rise of automation and material handling equipment in warehouses, particularly in logistics and e-commerce, is driving the adoption of hoist sling chains assemblies in these facilities.

Market Restraints

Despite its growth potential, the Hoist Sling Chains Assemblies Market faces several challenges:

High Initial Cost: The initial cost of purchasing hoist sling chains assemblies can be high, particularly for heavy-duty models used in industrial applications. This can limit market adoption in smaller industries with limited budgets.

Maintenance and Wear-and-Tear: Although hoist sling chains assemblies are built to be durable, they still require regular maintenance to ensure safe operations. Wear-and-tear from frequent use or exposure to harsh environmental conditions can lead to costly repairs or replacements.

Competition from Alternative Lifting Solutions: Hoist sling chains are not the only lifting solution available on the market. Alternatives, such as wire ropes, synthetic slings, and chain hoists, offer similar functionality, posing a challenge to the growth of the hoist sling chains assemblies market.

Raw Material Price Fluctuations: The prices of raw materials, such as high-strength steel and alloys, can fluctuate due to market conditions, affecting the overall cost of manufacturing hoist sling chains assemblies.

Market Opportunities

The Hoist Sling Chains Assemblies Market presents several opportunities for growth:

Expanding Construction and Industrial Sectors: The increasing demand for hoisting and lifting solutions in the construction and manufacturing industries presents significant opportunities for hoist sling chains assemblies. As urbanization and infrastructure development continue to grow, particularly in developing economies, the need for safe and efficient lifting solutions will continue to rise.

Technological Innovations: There is an opportunity for manufacturers to develop advanced hoist sling chains with enhanced durability, corrosion resistance, and weight-bearing capacity. Integrating smart technologies, such as sensors for monitoring load weight and chain tension, could further improve the functionality of hoist sling chains assemblies.

Focus on Sustainability: The growing focus on sustainability in industrial operations presents opportunities for hoist sling chain manufacturers to develop environmentally friendly products. This includes using recyclable materials, reducing energy consumption in manufacturing processes, and designing chains that have a longer lifespan to reduce waste.

Emerging Markets: As industrialization accelerates in emerging markets such as China, India, and Latin America, the demand for hoist sling chains assemblies is expected to rise, particularly in the construction, automotive, and logistics sectors.

Market Dynamics

The Hoist Sling Chains Assemblies Market is influenced by several key dynamics:

Technological Advancements in Manufacturing: Manufacturers are continually innovating in terms of design and material science to develop hoist sling chains that are more durable, efficient, and cost-effective. Automation and robotic systems in the manufacturing process are also improving production efficiency.

Regulatory Environment: Governments around the world are tightening safety regulations concerning lifting operations, which is driving the demand for high-quality hoist sling chains that meet stringent safety standards. Compliance with these regulations is critical for businesses to avoid penalties and ensure worker safety.

Industrial Growth: The growing industrialization and urbanization in emerging economies are fueling the demand for hoisting and lifting solutions, which directly impacts the market for hoist sling chains assemblies.

Regional Analysis

The Hoist Sling Chains Assemblies Market is segmented by region, with the following key trends:

North America: North America, particularly the United States, has a mature market for hoist sling chains assemblies due to the established construction and manufacturing industries. The focus on safety standards and regulations is driving the demand for high-quality hoisting equipment.

Europe: Europe’s market for hoist sling chains assemblies is growing steadily, with strong demand from industries such as automotive, logistics, and construction. The region is known for stringent safety regulations, which are boosting the market for high-performance lifting equipment.

Asia-Pacific: The Asia-Pacific region is expected to experience the highest growth in the hoist sling chains assemblies market due to rapid industrialization, particularly in China and India. The growing construction and manufacturing sectors are driving the demand for lifting solutions.

Latin America: Latin America is witnessing steady growth in the hoist sling chains assemblies market, driven by infrastructure development projects in countries like Brazil and Mexico.

Middle East & Africa: The Middle East and Africa are seeing moderate growth in the hoist sling chains assemblies market, driven by increasing industrial activity, especially in construction and oil & gas sectors.

Competitive Landscape

Leading companies in the Hoist Sling Chains Assemblies Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

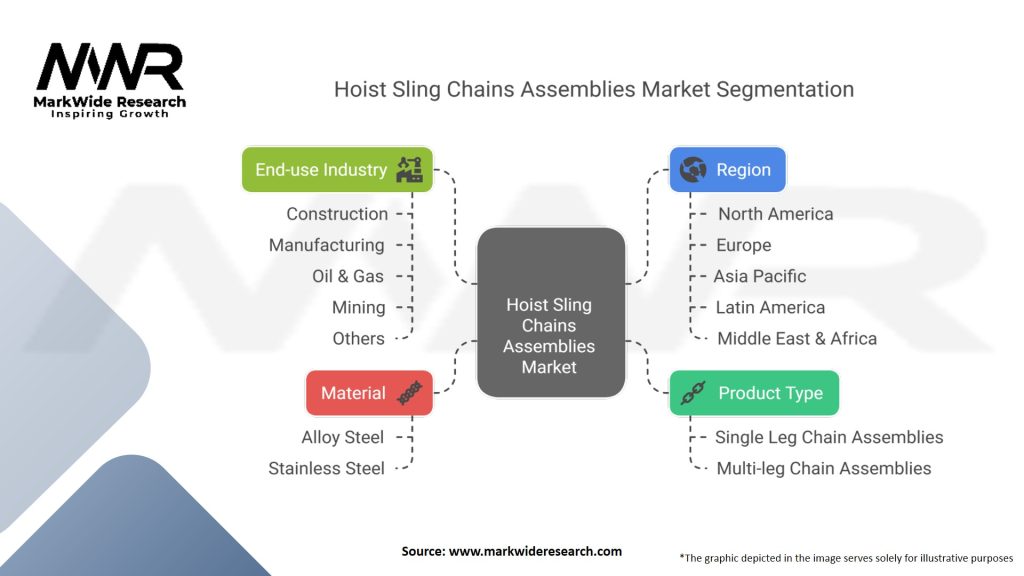

Segmentation

The Hoist Sling Chains Assemblies Market can be segmented based on:

Type: Single Chain Assemblies, Double Chain Assemblies, Custom Chain Assemblies.

Application: Construction, Manufacturing, Automotive, Oil & Gas, Logistics, Other Industrial Applications.

Region: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa.

Category-wise Insights

Construction: The construction industry is the largest end-user of hoist sling chains assemblies due to the growing need for material handling solutions in large-scale projects.

Automotive: In the automotive industry, hoist sling chains assemblies are used for lifting and moving heavy components, contributing significantly to market growth.

Key Benefits for Industry Participants and Stakeholders

Increased Operational Efficiency: High-quality hoist sling chains assemblies improve operational efficiency by ensuring safe, smooth, and reliable lifting operations.

Safety Compliance: By using reliable hoist sling chains assemblies, industries ensure compliance with safety regulations, reducing the risk of accidents and improving workplace safety.

Long-Term Cost Savings: Durable hoist sling chains assemblies reduce maintenance and replacement costs over time, making them a cost-effective solution for industrial lifting operations.

SWOT Analysis

Strengths:

High demand from growing industrial sectors.

Essential component in material handling and lifting operations.

Weaknesses:

High production and maintenance costs.

Dependency on fluctuating raw material prices.

Opportunities:

Growing industrialization in emerging economies.

Advancements in design and material technology.

Threats:

Competition from alternative lifting solutions.

Economic downturns affecting demand in certain sectors.

Market Key Trends

Integration of Smart Technologies: The growing integration of smart technologies such as sensors and IoT in hoist sling chains assemblies is enhancing safety and operational efficiency.

Sustainability Focus: Manufacturers are focusing on producing more eco-friendly hoist sling chains assemblies with recyclable materials to meet sustainability demands.

Hoist Sling Chains Assemblies: Covid-19 Impact

The Covid-19 pandemic has had a significant impact on the hoist sling chains assemblies market. The pandemic has disrupted global supply chains and caused economic uncertainty, which has impacted market growth.

However, the pandemic has also highlighted the importance of hoist chains and slings in various industries, particularly in the healthcare sector, where hoist chains and slings are used to lift and transport patients.

Hoist Sling Chains Assemblies: Key Industry Developments

The hoist sling chains assemblies market is a rapidly evolving industry that is constantly developing new products and technologies. Some of the key industry developments include:

Hoist Sling Chains Assemblies: Analyst Suggestions

Analysts suggest that manufacturers should focus on developing innovative products and technologies that can help improve the efficiency, safety, and reliability of hoist chains and slings. They also suggest that manufacturers should focus on reducing the cost of hoist chains and slings to make them more accessible to small and medium-sized businesses.

Hoist Sling Chains Assemblies: Future Outlook

The hoist sling chains assemblies market is expected to continue to grow at a rapid pace during the forecast period from 2021 to 2028. The market is driven by increasing demand from various industries, the growing need for safe and efficient lifting and moving of heavy loads, and the rising adoption of automation in manufacturing and other industries.

The key players in the market are expected to continue to focus on developing innovative products and technologies that can help improve the efficiency, safety, and reliability of hoist chains and slings. The market is also expected to witness increasing adoption of electric hoist chains and slings and automation in various industries.

Hoist Sling Chains Assemblies: Conclusion

The hoist sling chains assemblies market is a rapidly growing industry that offers several opportunities for growth and innovation. The market is driven by increasing demand from various industries, the growing need for safe and efficient lifting and moving of heavy loads, and the rising adoption of automation in manufacturing and other industries.

The key players in the market are focused on developing innovative products and technologies that can help improve the efficiency, safety, and reliability of hoist chains and slings. The market is expected to continue to grow at a rapid pace during the forecast period from 2021 to 2028, driven by increasing demand from various industries and the growing adoption of electric hoist chains and slings and automation in various industries. However, the high cost of hoist chains and slings and competition from alternative lifting and moving technologies such as cranes may be a barrier to adoption.

Hoist Sling Chains Assemblies Market:

| Segmentation | Details |

|---|---|

| Product Type | Single Leg Chain Assemblies, Multi-leg Chain Assemblies |

| Material | Alloy Steel, Stainless Steel |

| End-use Industry | Construction, Manufacturing, Oil & Gas, Mining, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Hoist Sling Chains Assemblies Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at