444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The connected mining market in Japan is witnessing steady growth, fueled by technological advancements, government initiatives to promote digitalization in the mining sector, and the need for sustainable mining practices. Connected mining involves the integration of advanced technologies such as Internet of Things (IoT), artificial intelligence (AI), and automation to optimize mining operations and enhance productivity, safety, and environmental sustainability. With Japan being a key player in the global mining industry, the adoption of connected mining solutions is expected to accelerate, revolutionizing the way mining activities are conducted in the country.

Meaning

Connected mining refers to the use of digital technologies and interconnected systems to optimize various aspects of mining operations, including exploration, extraction, processing, and transportation of minerals. By leveraging IoT sensors, data analytics, and communication networks, connected mining enables real-time monitoring, predictive maintenance, and remote operation of mining equipment and assets. This approach improves efficiency, reduces costs, and enhances safety in the mining industry, making it a strategic imperative for mining companies in Japan.

Executive Summary

The Japan connected mining market presents promising opportunities for growth and innovation, driven by the convergence of digital technologies, increasing demand for minerals, and the imperative for sustainability in the mining sector. Key market players are focusing on developing innovative solutions tailored to the unique requirements of the Japanese mining industry, thereby creating new opportunities for growth and differentiation. However, challenges such as data security concerns, regulatory compliance, and the need for skilled workforce pose hurdles to market expansion. Overall, the Japan connected mining market offers significant potential for stakeholders willing to embrace digital transformation and sustainability.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Japan connected mining market operates within a dynamic ecosystem influenced by various internal and external factors. These dynamics shape market trends, opportunities, and challenges, impacting the strategies and decisions of industry stakeholders.

Regional Analysis

The connected mining market in Japan exhibits regional variations influenced by factors such as mineral reserves, infrastructure development, regulatory frameworks, and economic conditions. Regions with significant mining activities, such as Hokkaido, Kyushu, and Tohoku, offer attractive opportunities for the deployment of connected mining solutions.

Competitive Landscape

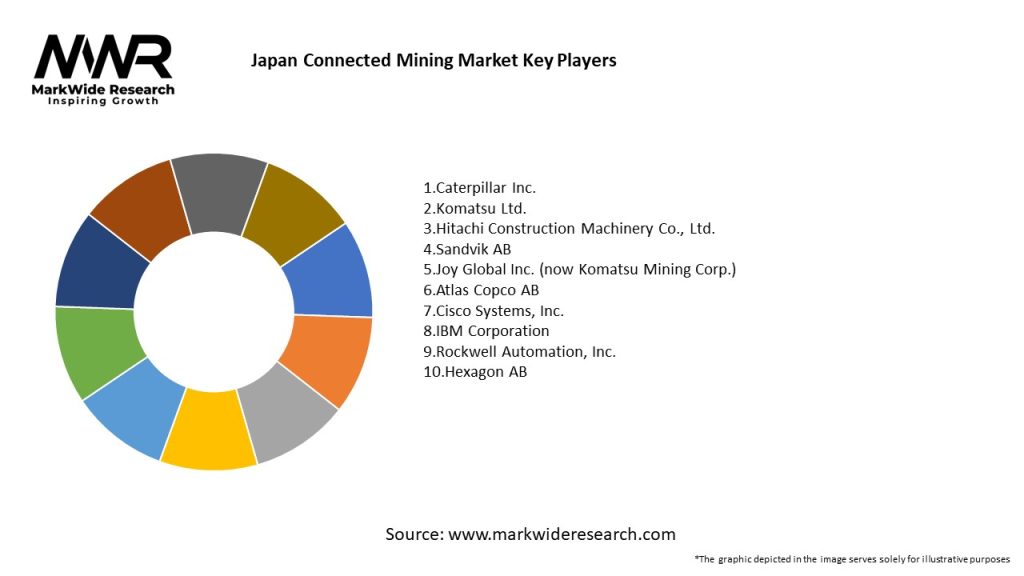

The competitive landscape of the Japan connected mining market is characterized by the presence of multinational corporations, technology providers, and local players offering a wide range of solutions and services. Key market players include:

These companies compete based on factors such as product innovation, technological expertise, market reach, and customer relationships. Strategic partnerships, acquisitions, and investments in R&D are key strategies adopted by market players to gain a competitive edge in the Japan connected mining market.

Segmentation

The Japan connected mining market can be segmented based on various factors, including technology type, application, and end-user industry. Common segments include:

Segmentation provides a structured approach to understanding the diverse needs and requirements of different segments within the Japan connected mining market, enabling companies to tailor their solutions and strategies accordingly.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The Japan connected mining market offers several benefits for industry participants and stakeholders:

SWOT Analysis

A SWOT analysis provides insights into the strengths, weaknesses, opportunities, and threats facing the Japan connected mining market:

Understanding these factors through a SWOT analysis helps mining companies and industry stakeholders formulate strategies to capitalize on strengths, address weaknesses, exploit opportunities, and mitigate threats in the Japan connected mining market.

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has accelerated the adoption of connected mining solutions in Japan, driven by the need for remote operation, social distancing, and business continuity. Mining companies have implemented digital technologies and automation to minimize onsite personnel, reduce health risks, and ensure uninterrupted operations during the pandemic.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the Japan connected mining market is positive, with continued growth expected driven by digitalization, sustainability initiatives, and innovation. Mining companies in Japan are likely to invest in advanced technologies, adopt sustainable practices, and collaborate with ecosystem partners to enhance competitiveness and resilience in the evolving market landscape.

Conclusion

In conclusion, the Japan connected mining market presents significant opportunities for growth and innovation, driven by digital transformation, sustainability imperatives, and the quest for operational excellence. Despite challenges such as skills shortage, regulatory compliance, and initial investment costs, the market offers promising prospects for mining companies, technology providers, and other stakeholders willing to embrace digitalization and sustainability. By leveraging advanced technologies, fostering collaboration, and prioritizing sustainability, the Japan connected mining market can unlock new value, drive economic growth, and contribute to a more sustainable future.

Japan Connected Mining Market:

| Segmentation | Details |

|---|---|

| Technology | Wearable Devices, Remote Monitoring Systems, Autonomous Vehicles |

| Application | Surface Mining, Underground Mining |

| Region | Japan |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies for Japan Connected Mining Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at