444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The North America Digital Textile Printing Machine market stands at the forefront of a transformative era in fabric printing. Digital textile printing has gained prominence as a technology that revolutionizes the traditional textile industry, offering advantages such as customization, efficiency, and sustainability. This market overview explores the dynamics, meaning, and executive summary of the North America Digital Textile Printing Machine market.

Meaning

Digital textile printing involves the use of specialized machines to apply digital images directly onto fabric. Unlike conventional methods that rely on screens or rollers, digital textile printing allows for precise and detailed designs, vibrant colors, and the ability to print small quantities. This technology caters to various applications, including fashion, home textiles, and promotional products.

Executive Summary

The North America Digital Textile Printing Machine market is experiencing significant growth, fueled by factors such as the demand for customized and sustainable textiles, advancements in printing technologies, and a shift towards on-demand production. While presenting lucrative opportunities, the market also faces challenges that necessitate a comprehensive understanding of key market insights, drivers, restraints, and opportunities.

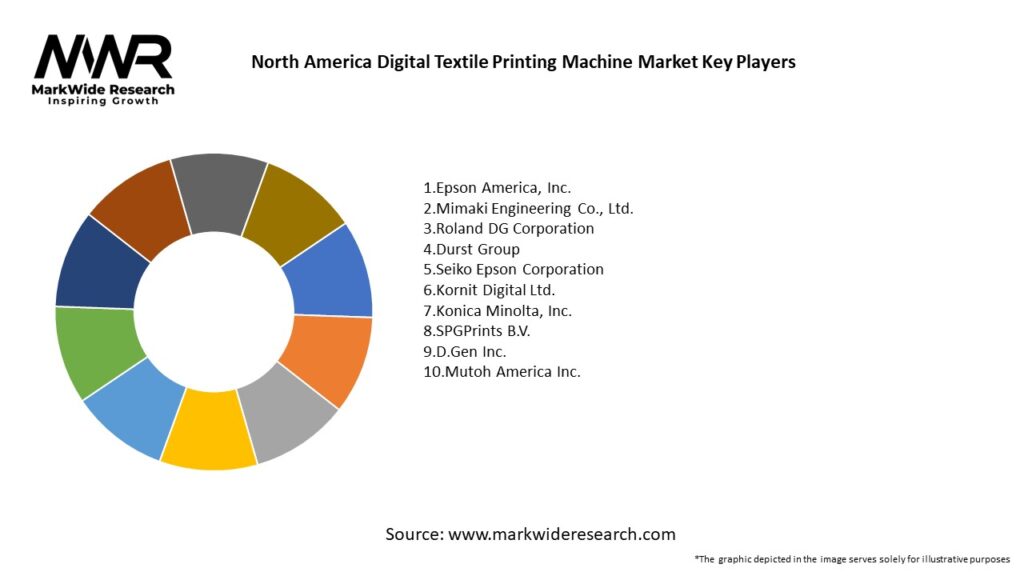

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The North America Digital Textile Printing Machine market operates in a dynamic environment shaped by technological advancements, consumer trends, and industry collaborations. Key factors influencing market dynamics include economic conditions, regulatory changes, and the evolving landscape of the textile and fashion industries.

Regional Analysis

The market’s performance in North America exhibits variations influenced by factors such as economic conditions, technological adoption, and the prevalence of sustainability initiatives. Let’s delve into a closer look at the regional dynamics:

United States: The United States, being a major player in the textile and fashion industry, drives significant demand for digital textile printing machines. The emphasis on sustainable practices and the vibrant e-commerce landscape contribute to the adoption of digital printing technologies.

Canada: Canada’s textile industry is characterized by a focus on innovation and sustainability. Digital textile printing aligns with these values, presenting opportunities for growth. The country’s diverse market demands cater to various applications, from fashion to home furnishings.

Competitive Landscape

Leading Companies in the North America Digital Textile Printing Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The North America Digital Textile Printing Machine market can be segmented based on various factors, including:

Segmentation allows for a detailed analysis of specific market segments, enabling manufacturers to tailor their offerings to meet the unique needs of different industries and applications.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

A SWOT analysis provides insights into the strengths, weaknesses, opportunities, and threats within the North America Digital Textile Printing Machine market:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has had varying impacts on the North America Digital Textile Printing Machine market. While disruptions in the supply chain and reduced consumer spending initially affected the industry, the emphasis on e-commerce and the demand for personalized products provided opportunities for recovery. The pandemic underscored the importance of digital printing’s flexibility and adaptability in responding to market challenges.

Key Industry Developments

Analyst Suggestions

Future Outlook

The North America Digital Textile Printing Machine market is poised for continued growth, driven by technological innovation, sustainability trends, and the dynamic landscape of the textile industry. The ability to adapt to changing consumer preferences, collaborate with key stakeholders, and invest in research and development will be critical for manufacturers to thrive in this evolving market. As digital textile printing becomes increasingly integral to the textile and fashion sectors, the future holds promising opportunities for those at the forefront of innovation and sustainability in the industry.

Conclusion

In conclusion, the North America Digital Textile Printing Machine market represents a pivotal sector in the evolution of textile printing. With a focus on customization, sustainability, and technological advancements, the market is navigating a transformative journey. Industry participants, from manufacturers to end-users, play crucial roles in shaping the trajectory of this market. As the demand for unique, sustainable, and on-demand textile solutions continues to rise, the North America Digital Textile Printing Machine market stands as a beacon of innovation in the broader landscape of the textile industry.

North America Digital Textile Printing Machine Market

| Segment | Description |

|---|---|

| Ink Type | Sublimation, Pigment, Reactive, Acid, Others |

| Application | Clothing/Garments, Home Textiles, Technical Textiles, Others |

| Country | United States, Canada, Mexico |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the North America Digital Textile Printing Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at