444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The 3D Printed Ophthalmic Implants market is witnessing substantial growth due to the convergence of advanced manufacturing technologies, personalized medicine, and increasing prevalence of ophthalmic disorders worldwide. Ophthalmic implants, customized through 3D printing techniques, offer precise anatomical fit, enhanced biocompatibility, and improved surgical outcomes for patients with conditions such as cataracts, glaucoma, and retinal disorders. With the advent of innovative materials and digital imaging technologies, 3D printed ophthalmic implants represent a paradigm shift in ophthalmic surgery, catering to the evolving needs of patients and healthcare providers.

Meaning

3D Printed Ophthalmic Implants refer to customized medical devices used in ophthalmic surgery, fabricated using additive manufacturing techniques such as 3D printing. These implants are designed to address specific anatomical defects, vision impairments, or ocular disorders, providing tailored solutions for patients undergoing cataract surgery, glaucoma treatment, corneal transplantation, or retinal repair. By leveraging patient-specific imaging data and computer-aided design (CAD) software, 3D printed ophthalmic implants offer precision, accuracy, and biocompatibility, optimizing surgical outcomes and patient satisfaction.

Executive Summary

The 3D Printed Ophthalmic Implants market is experiencing rapid growth driven by advancements in additive manufacturing technologies, expanding applications in ophthalmology, and the rising demand for personalized treatment options. Key market insights underscore the transformative impact of 3D printing on ophthalmic surgery, enabling customized implant designs, improved surgical precision, and enhanced patient care. As healthcare providers embrace digitalization and patient-centric approaches, the adoption of 3D printed ophthalmic implants is poised to revolutionize the field of ophthalmology and address unmet clinical needs.

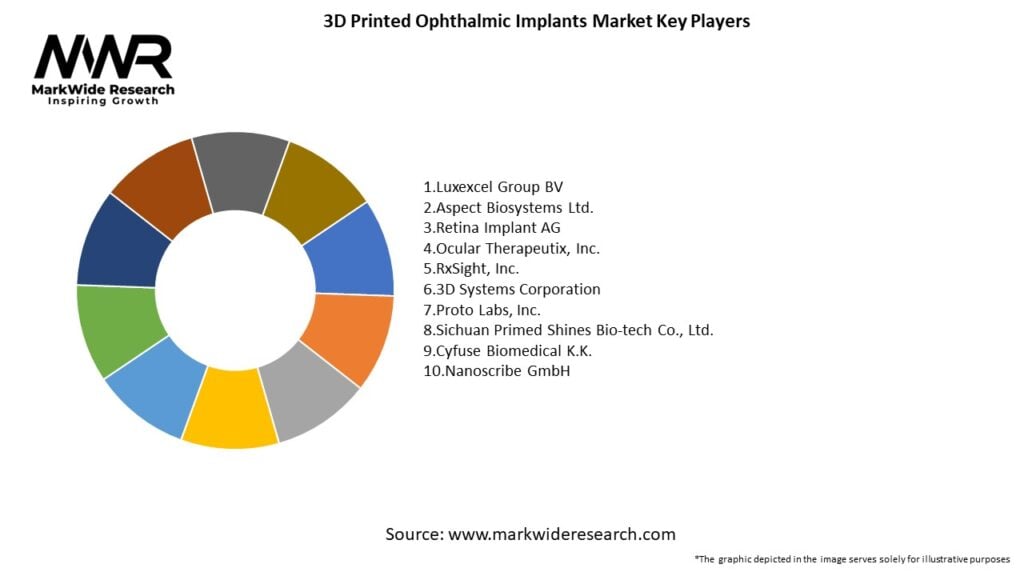

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The 3D Printed Ophthalmic Implants market operates within a dynamic ecosystem influenced by factors such as technological innovation, regulatory landscape, healthcare policy reforms, and patient preferences. Understanding these market dynamics is essential for stakeholders to navigate challenges, capitalize on opportunities, and drive sustainable growth in the rapidly evolving field of ophthalmic surgery and personalized medicine.

Regional Analysis

The 3D Printed Ophthalmic Implants market exhibits regional variations in adoption rates, regulatory frameworks, and healthcare infrastructure, reflecting diverse socioeconomic factors, cultural norms, and healthcare disparities across different geographic regions. Regional analysis enables stakeholders to identify market trends, target opportunities, and tailor strategies to specific regional needs and preferences.

Competitive Landscape

Leading Companies in 3D Printed Ophthalmic Implants Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The 3D Printed Ophthalmic Implants market can be segmented based on various factors, including implant type, material composition, surgical indication, and geographic region. Segmentation enables stakeholders to analyze market dynamics, target specific patient populations, and develop customized solutions tailored to clinical needs and market demand.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has accelerated the adoption of 3D printed ophthalmic implants, driven by the need for contactless consultations, remote surgical planning, and telemedicine solutions to mitigate infection risks and ensure patient safety. Despite temporary disruptions in supply chains and elective surgeries, the pandemic has underscored the importance of innovative technologies, digital health solutions, and personalized treatment options in ophthalmic practice, paving the way for sustained market growth and resilience in the post-pandemic era.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook of the 3D Printed Ophthalmic Implants market is characterized by a trajectory of sustained growth, driven by evolving technological landscapes, increasing clinical acceptance, and a growing emphasis on personalized healthcare. Several factors contribute to shaping the future of this market:

Conclusion

The 3D Printed Ophthalmic Implants market stands at the forefront of transformative change within the field of ophthalmology. The convergence of cutting-edge technologies, personalized medicine, and collaborative research is reshaping the landscape of ocular surgery. As the market continues to evolve, stakeholders should remain vigilant to emerging trends, invest in research and development, and collaborate across disciplines to unlock the full potential of 3D printed ophthalmic implants. The future promises not only enhanced clinical outcomes but also a paradigm shift towards patient-centric and precision-driven ophthalmic care. In navigating this future, the industry can look forward to improving the quality of life for countless individuals affected by various ocular conditions.

| Segmentation Details | Details |

|---|---|

| Implant Type | Corneal Implants, Intraocular Lenses, Retinal Implants, Others |

| Material | Polymers, Metals, Ceramics, Others |

| End-User | Hospitals, Ophthalmic Clinics, Ambulatory Surgical Centers |

| Region | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at