The electrical insulation tape market is a thriving sector within the global electrical industry. Electrical insulation tape, also known as electrical tape or insulating tape, is a type of pressure-sensitive adhesive tape used to insulate electrical wires and other conductive materials. It provides protection against electrical shock, moisture, and physical damage, making it an essential component in various electrical applications.

Electrical insulation tape is designed to safeguard electrical connections by preventing contact between conductive materials. It consists of a flexible backing material, such as PVC (polyvinyl chloride) or rubber, coated with a layer of adhesive on one side. The adhesive ensures a secure bond when the tape is applied to electrical wires, cables, or other components.

Executive Summary

The electrical insulation tape market has witnessed significant growth in recent years due to the increasing demand for reliable electrical insulation solutions across various industries. The market is driven by factors such as the expansion of the electrical and electronics sector, rapid urbanization, and the growing focus on energy efficiency.

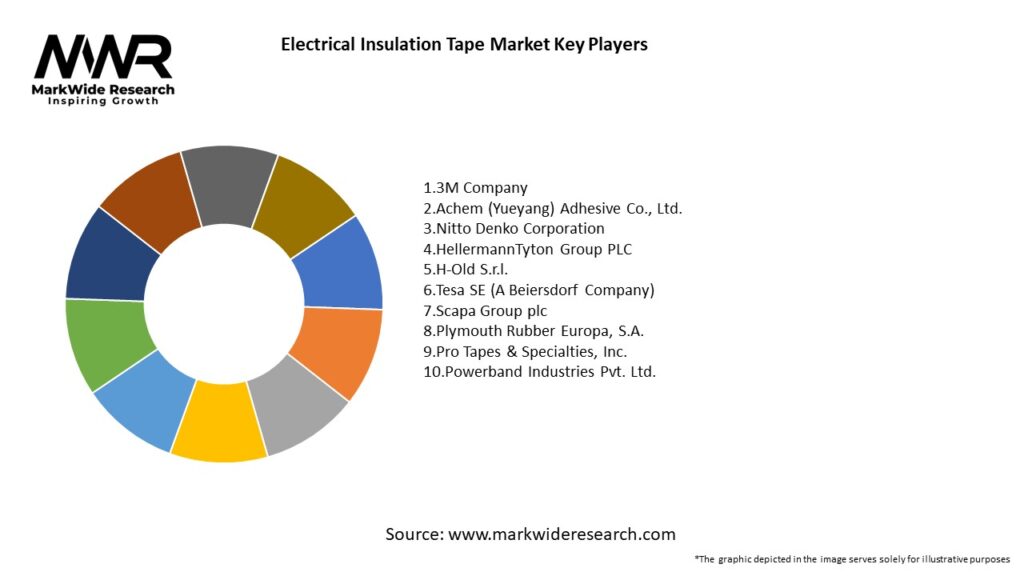

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

- Growing Demand for Electrical Insulation: The increasing adoption of electrical insulation tape can be attributed to the rising need for efficient electrical insulation in various applications, including residential, commercial, and industrial sectors.

- Technological Advancements: The market is witnessing continuous technological advancements, leading to the development of innovative electrical insulation tapes with enhanced performance characteristics, such as better heat resistance, high voltage insulation, and flame retardancy.

- Increasing Safety Regulations: Strict safety regulations imposed by governments and regulatory bodies regarding electrical installations and maintenance are driving the demand for reliable electrical insulation products, including insulation tapes.

- Shift Towards Sustainable Materials: With the growing focus on sustainability and environmental concerns, manufacturers are developing eco-friendly electrical insulation tapes that are free from harmful substances such as lead and mercury.

Market Drivers

- Expansion of the Electrical and Electronics Industry: The rapid growth of the electrical and electronics industry, driven by technological advancements and increasing consumer demand for electronic devices, is a major driver for the electrical insulation tape market.

- Urbanization and Infrastructure Development: The ongoing urbanization and infrastructure development projects across the globe require efficient electrical installations, fueling the demand for electrical insulation tapes.

- Growing Emphasis on Energy Efficiency: Energy conservation and efficiency have become paramount in today’s world. Electrical insulation tapes help reduce energy losses and enhance overall system efficiency, leading to increased demand from energy-conscious consumers and industries.

- Increasing Awareness of Electrical Safety: Rising awareness about the risks associated with electrical hazards has propelled the demand for electrical insulation tapes as a preventive measure to protect against electrical shocks and short circuits.

Market Restraints

- Availability of Substitutes: The presence of alternative insulation materials, such as heat-shrinkable tubing and insulating varnishes, poses a challenge to the growth of the electrical insulation tape market. These alternatives offer specific advantages and may be preferred in certain applications.

- Price Fluctuations of Raw Materials: The prices of raw materials used in the production of electrical insulation tapes, such as PVC and rubber, are subject to fluctuations, which can impact the overall manufacturing cost and pricing of the tapes.

- Intense Competition: The market is highly competitive, with numerous players vying for market share. Intense competition may result in price wars and affect the profitability of manufacturers.

- Stringent Regulations and Standards: Compliance with stringent regulations and standards related to electrical insulation materials and performance can be a challenge for manufacturers, especially those operating in multiple regions with varying requirements.

Market Opportunities

- Expansion in Emerging Markets: The electrical insulation tape market holds significant growth opportunities in emerging economies where the electrical and electronics sector is experiencing rapid development. These regions offer untapped potential for market players to establish a strong foothold.

- Demand for High-Performance Tapes: There is a growing demand for high-performance electrical insulation tapes that can withstand extreme temperatures, chemicals, and harsh environments. Manufacturers can capitalize on this opportunity by developing tapes with superior properties.

- Customization and Value-Added Services: Offering customized electrical insulation tapes tailored to specific requirements of end-users can help manufacturers differentiate themselves in the market. Additionally, providing value-added services such as technical support and training can enhance customer satisfaction and loyalty.

- Collaborations and Partnerships: Collaborating with key industry players, including electrical equipment manufacturers and distributors, can open up new avenues for market expansion. Joint ventures and partnerships can leverage synergies and increase market reach.

Market Dynamics

The electrical insulation tape market is characterized by intense competition, technological advancements, and the constant need for product innovation. The dynamics of the market are influenced by factors such as industry trends, customer preferences, government regulations, and economic conditions.

Regional Analysis

The electrical insulation tape market can be segmented into several regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Each region has its specific market dynamics, influenced by factors such as economic growth, infrastructure development, and technological advancements.

In North America, the market is driven by the presence of a well-established electrical and electronics industry and the adoption of stringent safety regulations. Europe is witnessing steady growth, fueled by increased emphasis on energy efficiency and environmental sustainability. Asia Pacific is the fastest-growing region, driven by rapid industrialization, urbanization, and infrastructure development.

Latin America and the Middle East and Africa present opportunities for market expansion due to ongoing infrastructure projects and the growing demand for electrical insulation solutions. However, these regions also face challenges such as price sensitivity and fluctuating economic conditions.

Competitive Landscape

Leading companies in the Electrical Insulation Tape Market:

- 3M Company

- Achem (Yueyang) Adhesive Co., Ltd.

- Nitto Denko Corporation

- HellermannTyton Group PLC

- H-Old S.r.l.

- Tesa SE (A Beiersdorf Company)

- Scapa Group plc

- Plymouth Rubber Europa, S.A.

- Pro Tapes & Specialties, Inc.

- Powerband Industries Pvt. Ltd.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

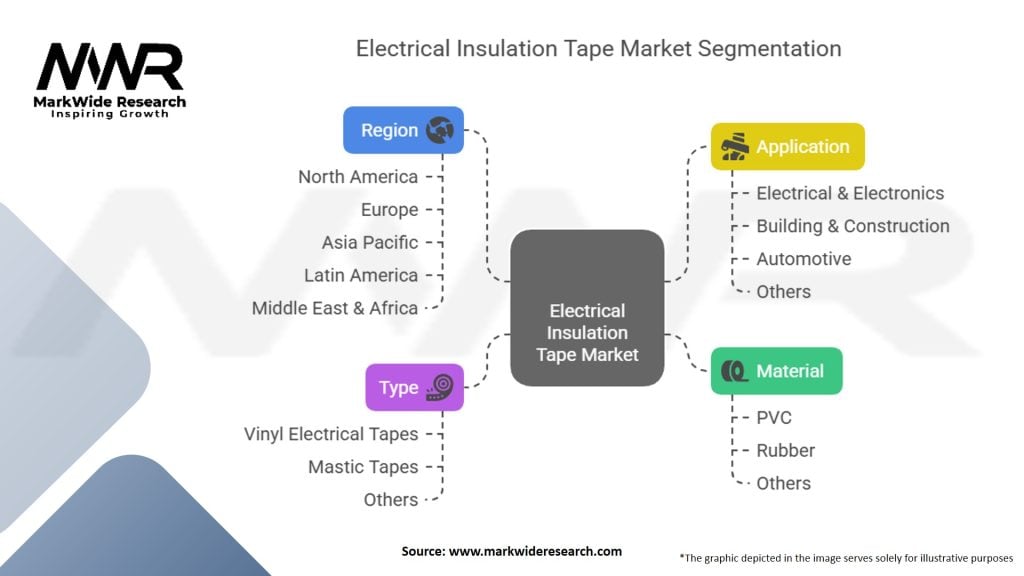

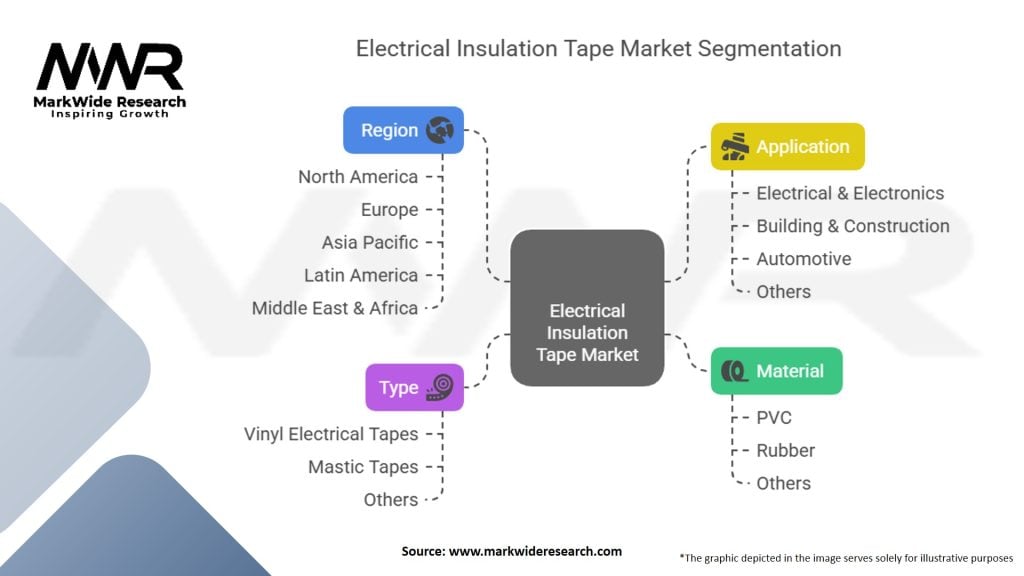

Segmentation

The electrical insulation tape market can be segmented based on various factors, including product type, backing material, voltage rating, end-use industry, and region.

By product type, the market can be segmented into vinyl electrical tape, rubber electrical tape, and others. Backing materials include PVC, rubber, and others. Voltage rating segments may include low voltage, medium voltage, and high voltage insulation tapes. End-use industries encompass residential, commercial, industrial, and others.

Geographically, the market can be segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

Category-wise Insights

- Vinyl Electrical Tape: Vinyl electrical tape is the most commonly used type of electrical insulation tape due to its excellent electrical insulation properties, ease of use, and cost-effectiveness. It finds extensive applications in residential, commercial, and industrial sectors.

- Rubber Electrical Tape: Rubber electrical tape offers superior flexibility and resistance to heat, moisture, and chemicals. It is often used in high-temperature applications and environments where extreme conditions are encountered.

- PVC Backing Material: PVC is widely used as a backing material for electrical insulation tapes due to its excellent electrical insulation properties, durability, and availability in various colors. It provides good adhesion and is suitable for a wide range of applications.

- Low Voltage Insulation Tapes: Low voltage insulation tapes are designed for applications with voltage levels below 600 volts. They are commonly used in residential, commercial, and light industrial installations.

- Medium Voltage Insulation Tapes: Medium voltage insulation tapes are specifically designed to withstand higher voltage levels, typically ranging from 1,000 to 35,000 volts. They find applications in power distribution systems, industrial machinery, and electrical infrastructure.

- High Voltage Insulation Tapes: High voltage insulation tapes are engineered to provide superior electrical insulation for applications involving extremely high voltage levels, exceeding 35,000 volts. They are used in power transmission, utility substations, and electrical equipment for heavy industries.

- Residential Sector: In the residential sector, electrical insulation tapes are widely used for electrical wiring, repairs, and maintenance. They provide insulation and protection against electrical shocks, ensuring safety for homeowners.

- Commercial Sector: In commercial buildings, electrical insulation tapes are utilized for various applications, including electrical installations, repairs, and maintenance of electrical systems. They play a crucial role in ensuring electrical safety and uninterrupted operation.

- Industrial Sector: The industrial sector is a significant consumer of electrical insulation tapes. They are employed in diverse industrial applications such as manufacturing, machinery, automation, and electrical equipment, providing insulation and protection in demanding environments.

Key Benefits for Industry Participants and Stakeholders

- Enhanced Electrical Safety: Electrical insulation tapes play a crucial role in ensuring electrical safety by providing insulation and protection against electrical shocks and short circuits. This benefit is particularly important in residential, commercial, and industrial settings.

- Extended Lifespan of Electrical Systems: By effectively insulating electrical connections, insulation tapes help extend the lifespan of electrical systems. They protect against moisture, corrosion, and physical damage, reducing the risk of system failures and costly repairs.

- Compliance with Safety Standards: The use of electrical insulation tapes enables industry participants to comply with safety standards and regulations imposed by governmental and regulatory bodies. This compliance ensures that electrical installations meet the required safety criteria.

- Versatile Applications: Electrical insulation tapes offer versatile applications across various industries, including electrical and electronics, automotive, aerospace, and construction. They can be used for wire harnessing, cable management, identification, and repairs, among other purposes.

- Cost-Effectiveness: Electrical insulation tapes provide a cost-effective solution for electrical insulation compared to alternative methods or materials. They are readily available, easy to use, and offer a reliable means of insulating electrical connections.

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis provides a comprehensive assessment of the electrical insulation tape market:

Strengths:

- Wide range of applications and end-use industries

- Established market players with strong brand presence

- Technological advancements leading to innovative product offerings

- Growing emphasis on energy efficiency and sustainability

Weaknesses:

- Availability of alternative insulation materials

- Price fluctuations of raw materials impacting manufacturing costs

- Intense competition leading to price wars and margin pressure

- Stringent compliance requirements and varying standards across regions

Opportunities:

- Expansion in emerging markets with rapid industrialization and urbanization

- Increasing demand for high-performance electrical insulation tapes

- Customization and value-added services to cater to specific customer needs

- Collaborations and partnerships for market expansion

Threats:

- Intense competition from existing players and new entrants

- Fluctuating economic conditions impacting market growth

- Substitutes and alternative insulation materials gaining market share

- Stringent regulations and compliance challenges across regions

Market Key Trends

- Adoption of Flame Retardant Tapes: There is a growing trend of using flame retardant electrical insulation tapes in applications where fire safety is a concern. These tapes are designed to resist ignition and inhibit the spread of flames, ensuring enhanced safety in critical environments.

- Focus on Eco-Friendly Solutions: Market players are increasingly focusing on developing eco-friendly electrical insulation tapes that are free from harmful substances. These tapes meet environmental regulations and address the growing demand for sustainable products.

- Integration of Smart Features: With the rise of smart technologies, electrical insulation tapes are being developed with smart features such as temperature sensing, moisture detection, and self-healing capabilities. These advanced tapes provide real-time monitoring and enhanced performance.

- Digitalization and Online Sales Channels: The market is witnessing a shift towards digitalization, with online sales channels becoming more prominent. Manufacturers are leveraging e-commerce platforms to reach a wider customer base and streamline the distribution process.

Covid-19 Impact

The Covid-19 pandemic has had a mixed impact on the electrical insulation tape market. While the initial disruption caused by lockdowns and supply chain disruptions affected the market, the subsequent recovery was driven by factors such as increased demand for electrical repairs and maintenance during remote working and the need for reliable electrical systems in healthcare facilities.

The pandemic has also accelerated digitalization, leading to a higher adoption of online sales channels and virtual interactions. Manufacturers have adapted to remote working arrangements and implemented stringent health and safety measures to ensure uninterrupted production and distribution of electrical insulation tapes.

Key Industry Developments

- Introduction of High-Temperature Tapes: Market players have introduced electrical insulation tapes capable of withstanding higher temperatures, expanding their applications in industries such as automotive, aerospace, and electronics manufacturing.

- Mergers and Acquisitions: Major players in the market have engaged in mergers and acquisitions to strengthen their market presence and expand their product portfolios. These strategic moves have facilitated technological collaborations and synergies among industry participants.

- Product Innovations: Manufacturers have focused on developing innovative electrical insulation tapes with advanced features such as UV resistance, high flexibility, and easy application. These innovations cater to the evolving needs of end-users and provide a competitive advantage.

- Strategic Partnerships: Collaborations between manufacturers and electrical equipment suppliers have become prevalent, allowing for joint product development and distribution. Such partnerships enable efficient supply chain management and enhanced customer reach.

Analyst Suggestions

- Continuous Product Innovation: Manufacturers should invest in research and development to introduce innovative electrical insulation tapes with advanced features and improved performance characteristics. This will help meet the evolving demands of customers and gain a competitive edge in the market.

- Focus on Sustainability: With the growing emphasis on sustainability, market players should develop eco-friendly electrical insulation tapes that comply with environmental regulations. Embracing sustainable practices and materials will enhance brand reputation and meet customer expectations.

- Geographic Expansion: Companies should explore opportunities for geographic expansion, particularly in emerging markets with significant growth potential. Establishing a strong presence in these regions will allow for increased market penetration and access to new customer segments.

- Strategic Partnerships and Collaborations: Collaborating with key industry players, including electrical equipment manufacturers and distributors, can provide access to new markets and synergistic opportunities. Partnerships can also enhance product development capabilities and expand the distribution network.

Future Outlook

The electrical insulation tape market is poised for significant growth in the coming years. Factors such as the expansion of the electrical and electronics industry, increasing emphasis on energy efficiency, and strict safety regulations will continue to drive market demand. Technological advancements and product innovations will further shape the market landscape, with a focus on high-performance tapes and eco-friendly solutions. Geographic expansion, strategic partnerships, and digitalization will be key strategies for industry participants to stay competitive and capitalize on emerging opportunities.

Conclusion

The electrical insulation tape market is witnessing robust growth due to the increasing demand for reliable electrical insulation solutions across various industries. The market is driven by factors such as the expansion of the electrical and electronics sector, rapid urbanization, and the growing focus on energy efficiency.

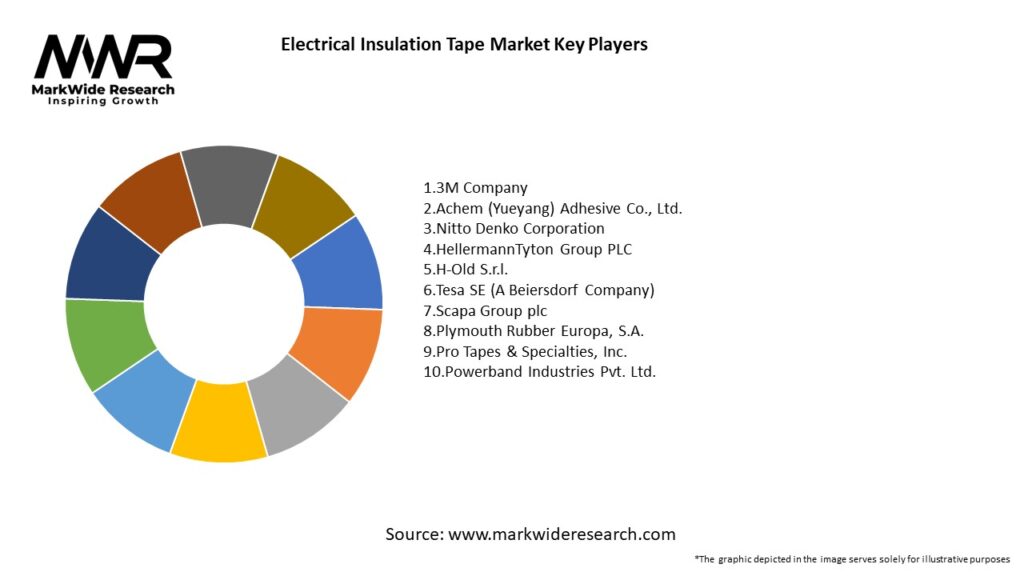

Leading companies in the Electrical Insulation Tape Market:

- 3M Company

- Achem (Yueyang) Adhesive Co., Ltd.

- Nitto Denko Corporation

- HellermannTyton Group PLC

- H-Old S.r.l.

- Tesa SE (A Beiersdorf Company)

- Scapa Group plc

- Plymouth Rubber Europa, S.A.

- Pro Tapes & Specialties, Inc.

- Powerband Industries Pvt. Ltd.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA