444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The 3D printing plastics market is a rapidly growing market with increasing demand for 3D printing technology in various industries. 3D printing, also known as additive manufacturing, is a process of creating a three-dimensional object from a digital file. It involves layering materials such as plastics, metals, and ceramics to create a final product. The 3D printing plastics market specifically focuses on the use of plastic materials in 3D printing.

The use of 3D printing plastics has gained traction in several industries including aerospace, automotive, healthcare, and consumer goods. It offers various advantages such as reduced material waste, improved design flexibility, and faster production time compared to traditional manufacturing processes. These advantages have led to an increase in the adoption of 3D printing technology in various industries, which has further fueled the growth of the 3D printing plastics market.

Meaning

3D printing plastics are materials that are specifically designed for use in 3D printing technology. These plastics are usually in the form of filaments or pellets, which are melted and extruded through a nozzle to create a three-dimensional object. The most commonly used 3D printing plastics include acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), polyethylene terephthalate glycol (PETG), and nylon. These plastics have different properties such as strength, flexibility, and durability, which make them suitable for different applications.

Executive Summary

The 3D printing plastics market is a rapidly growing market that is expected to reach a value of USD 1.97 billion by 2026, growing at a CAGR of 23.5% during the forecast period. The market is primarily driven by the increasing adoption of 3D printing technology in various industries and the advantages offered by 3D printing plastics such as reduced material waste and improved design flexibility. However, the market is also facing some challenges such as the high cost of 3D printing plastics and the limited availability of high-quality materials.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The adoption of 3D printing technology is increasing rapidly in various industries such as aerospace, automotive, healthcare, and consumer goods. 3D printing technology offers various advantages such as reduced material waste, improved design flexibility, and faster production time compared to traditional manufacturing processes. These advantages have led to an increase in the adoption of 3D printing technology, which has further fueled the growth of the 3D printing plastics market.

3D printing plastics offer various advantages such as reduced material waste, improved design flexibility, and faster production time compared to traditional manufacturing processes. These advantages have led to an increase in the adoption of 3D printing technology in various industries, which has further fueled the growth of the 3D printing plastics market.

Market Restraints

The cost of 3D printing plastics is higher compared to traditional manufacturing materials, which makes it a significant challenge for the growth of the market. The high cost of 3D printing plastics can be attributed to the limited availability of high-quality materials and the complexity of the manufacturing process.

The limited availability of high-quality 3D printing plastics is a major challenge for the growth of the market. This is because the quality of 3D printed parts is directly dependent on the quality of the materials used. Therefore, the limited availability of high-quality materials can lead to lower quality 3D printed parts, which can affect the adoption of 3D printing technology in various industries.

Market Opportunities

The growing demand for customized products presents a significant opportunity for the growth of the 3D printing plastics market. 3D printing technology offers the ability to create customized products quickly and at a lower cost compared to traditional manufacturing processes. This advantage has led to an increase in the adoption of 3D printing technology, especially in industries such as healthcare, where customized products are required.

The increasing investment in research and development by companies operating in the 3D printing plastics market presents a significant opportunity for the growth of the market. The investment in research and development is aimed at developing new and high-quality 3D printing materials that can be used in various industries. This development will help to overcome the challenges faced by the market, such as the high cost of materials and the limited availability of high-quality materials.

Market Dynamics

The Introduction of New and Innovative 3D Printing Materials is a significant trend in the 3D printing plastics market. The development of new and innovative materials helps to overcome the challenges faced by the market, such as the high cost of materials and the limited availability of high-quality materials. Companies operating in the market are investing in research and development to develop new and innovative materials that can be used in various industries.

The increasing demand for 3D printed medical devices is a significant trend in the 3D printing plastics market. 3D printing technology offers the ability to create customized medical devices quickly and at a lower cost compared to traditional manufacturing processes. This advantage has led to an increase in the adoption of 3D printing technology in the healthcare industry, especially for the production of medical devices such as implants and prosthetics.

Regional Analysis

North America is expected to hold the largest share of the 3D printing plastics market during the forecast period. This can be attributed to the increasing adoption of 3D printing technology in various industries, such as aerospace, automotive, and healthcare, and the presence of major players in the region. Asia-Pacific is expected to be the fastest-growing region during the forecast period. This can be attributed to the increasing investment in research and development and the growing demand for customized products in the region.

Competitive Landscape

Leading Companies in the 3D Printing Plastics Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

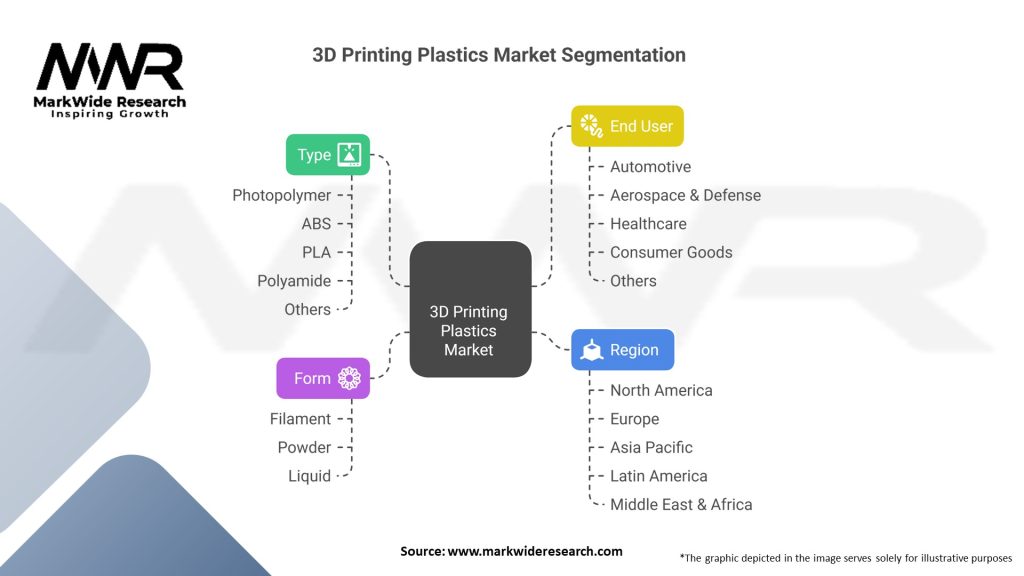

Segmentation

The 3D printing plastics market can be segmented based on type, form, application, and end-use industry.

Category-wise Insights

Acrylonitrile butadiene styrene (ABS) is a commonly used 3D printing plastic. It is known for its strength and durability and is commonly used in the automotive and aerospace industries. ABS is also known for its high-temperature resistance, which makes it suitable for use in applications that require high-temperature resistance.

Polylactic acid (PLA) is a biodegradable 3D printing plastic. It is known for its ease of use and low toxicity, which makes it suitable for use in the healthcare industry. PLA is also known for its low melting point, which makes it suitable for use in applications that require low-temperature resistance.

Polyethylene terephthalate glycol (PETG) is a 3D printing plastic known for its clarity and toughness. It is commonly used in the consumer goods industry for the production of products such as water bottles and food containers. PETG is also known for its ease of use and low shrinkage, which makes it suitable for use in applications that require high accuracy.

Nylon is a 3D printing plastic known for its strength and flexibility. It is commonly used in the automotive and aerospace industries for the production of parts that require high strength and durability. Nylon is also known for its high-temperature resistance, which makes it suitable for use in applications that require high-temperature resistance.

Key Benefits for Industry Participants and Stakeholders

3D printing technology offers the advantage of reduced material waste compared to traditional manufacturing processes. This advantage has led to an increase in the adoption of 3D printing technology, especially in industries such as aerospace and automotive, where the production of parts can lead to a significant amount of material waste.

3D printing technology offers the advantage of improved design flexibility compared to traditional manufacturing processes. This advantage has led to an increase in the adoption of 3D printing technology, especially in industries such as healthcare, where customized products are required.

3D printing technology offers the advantage of faster production time compared to traditional manufacturing processes. This advantage has led to an increase in the adoption of 3D printing technology, especially in industries such as consumer goods, where the production of products needs to be fast and efficient.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

The adoption of 3D printing technology is increasing rapidly in the healthcare industry. This is due to the advantages offered

Market Key Trends

The adoption of 3D printing technology is increasing rapidly in the healthcare industry. This is due to the advantages offered by 3D printing technology, such as the ability to create customized medical devices quickly and at a lower cost compared to traditional manufacturing processes. The healthcare industry has also witnessed the production of various 3D printed medical devices such as implants and prosthetics.

The Growing Demand for Sustainable Materials is a significant trend in the 3D printing plastics market. 3D printing technology offers the advantage of reduced material waste compared to traditional manufacturing processes. The use of sustainable materials in 3D printing technology can further reduce material waste and improve the sustainability of the manufacturing process.

The increasing investment in research and development by companies operating in the 3D printing plastics market is a significant trend. The investment is aimed at developing new and innovative materials that can be used in various industries. This development will help to overcome the challenges faced by the market, such as the high cost of materials and the limited availability of high-quality materials.

Covid-19 Impact

The Covid-19 pandemic has had a mixed impact on the 3D printing plastics market. The pandemic has led to an increase in the demand for 3D printed medical devices such as face shields and ventilator parts. However, the pandemic has also led to a decrease in the demand for 3D printed products in other industries such as aerospace and automotive. The pandemic has also led to disruptions in the supply chain, which has affected the production of 3D printing plastics.

Key Industry Developments

The introduction of new and innovative 3D printing materials is a significant development in the 3D printing plastics market. Companies operating in the market are investing in research and development to develop new and innovative materials that can be used in various industries. For example, BASF SE introduced Ultrafuse 316LX, a new 3D printing material that can be used for the production of metal parts.

Partnerships and collaborations are a significant development in the 3D printing plastics market. Companies are partnering and collaborating to develop new and innovative 3D printing materials and technologies. For example, Evonik Industries AG partnered with Cubicure GmbH to develop new photopolymer materials for 3D printing.

Analyst Suggestions

Companies operating in the 3D printing plastics market should focus on research and development to develop new and innovative materials that can be used in various industries. The development of new materials can help to overcome the challenges faced by the market, such as the high cost of materials and the limited availability of high-quality materials.

Collaboration and partnerships between companies operating in the 3D printing plastics market can help to accelerate the development of new and innovative materials and technologies. Collaboration and partnerships can also help to overcome the challenges faced by the market, such as the high cost of materials and the limited availability of high-quality materials.

Future Outlook

The 3D printing plastics market is expected to continue to grow in the future, driven by the increasing adoption of 3D printing technology in various industries and the advantages offered by 3D printing plastics. The market is expected to face challenges such as the high cost of materials and the limited availability of high-quality materials. However, the market is also expected to witness opportunities such as the growing demand for customized products and the increasing investment in research and development.

Conclusion

The 3D printing plastics market is a rapidly growing market driven by the increasing adoption of 3D printing technology in various industries and the advantages offered by 3D printing plastics such as reduced material waste and improved design flexibility. The market is facing challenges such as the high cost of materials and the limited availability of high-quality materials, but it is also witnessing opportunities such as the growing demand for customized products and the increasing investment in research and development.

The healthcare industry is expected to be a major driver of the 3D printing plastics market in the future due to the advantages offered by 3D printing technology in the production of customized medical devices. Sustainable materials are also expected to gain traction in the market due to the growing demand for sustainable manufacturing processes.

Overall, the future outlook for the 3D printing plastics market is positive, with the market expected to continue to grow in the coming years.

What are 3D printing plastics?

3D printing plastics refer to a variety of thermoplastic materials used in additive manufacturing processes to create three-dimensional objects. These materials include acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), and nylon, among others, which are chosen for their specific properties and applications in various industries.

What companies are leading the 3D printing plastics market?

Leading companies in the 3D printing plastics market include Stratasys, Materialise, and BASF, which are known for their innovative materials and technologies. Other notable players include 3D Systems and Ultimaker, among others.

What are the key drivers of growth in the 3D printing plastics market?

Key drivers of growth in the 3D printing plastics market include the increasing demand for customized products, advancements in printing technology, and the rising adoption of 3D printing in industries such as aerospace, automotive, and healthcare.

What challenges does the 3D printing plastics market face?

The 3D printing plastics market faces challenges such as material limitations, high production costs, and regulatory hurdles that can hinder widespread adoption. Additionally, the need for skilled labor and the variability in print quality can pose significant obstacles.

What opportunities exist in the 3D printing plastics market?

Opportunities in the 3D printing plastics market include the development of new materials with enhanced properties, the expansion of applications in sectors like construction and consumer goods, and the potential for sustainable practices through recycling and bio-based plastics.

What trends are shaping the 3D printing plastics market?

Trends shaping the 3D printing plastics market include the growing interest in sustainable materials, the integration of artificial intelligence in design processes, and the increasing use of multi-material printing techniques to enhance functionality and aesthetics.

3D Printing Plastics Market

| Segmentation | Details |

|---|---|

| Type | Photopolymer, ABS, PLA, Polyamide, Others |

| Form | Filament, Powder, Liquid |

| End User | Automotive, Aerospace & Defense, Healthcare, Consumer Goods, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the 3D Printing Plastics Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at