444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The 3D printing medical devices market has been experiencing significant growth in recent years. With advancements in technology and increased adoption of additive manufacturing in healthcare, the market for 3D printed medical devices is expected to witness substantial expansion. 3D printing, also known as additive manufacturing, involves the creation of three-dimensional objects using a layer-by-layer printing process. This innovative technology has revolutionized various industries, including healthcare.

3D printing medical devices refer to the production of custom-made medical devices using additive manufacturing techniques. This process enables the creation of complex and personalized medical devices that meet the specific needs of patients. By leveraging 3D printing technology, medical professionals can design and manufacture implants, prosthetics, surgical instruments, and anatomical models with enhanced precision and efficiency.

Executive Summary

The 3D printing medical devices market has experienced robust growth in recent years due to the numerous advantages it offers over traditional manufacturing methods. The ability to produce highly customized and patient-specific devices, reduced production time, and cost-effectiveness are some of the key factors driving the adoption of 3D printing in the medical field. This market is poised for further expansion as technological advancements continue to improve the quality and capabilities of 3D printed medical devices.

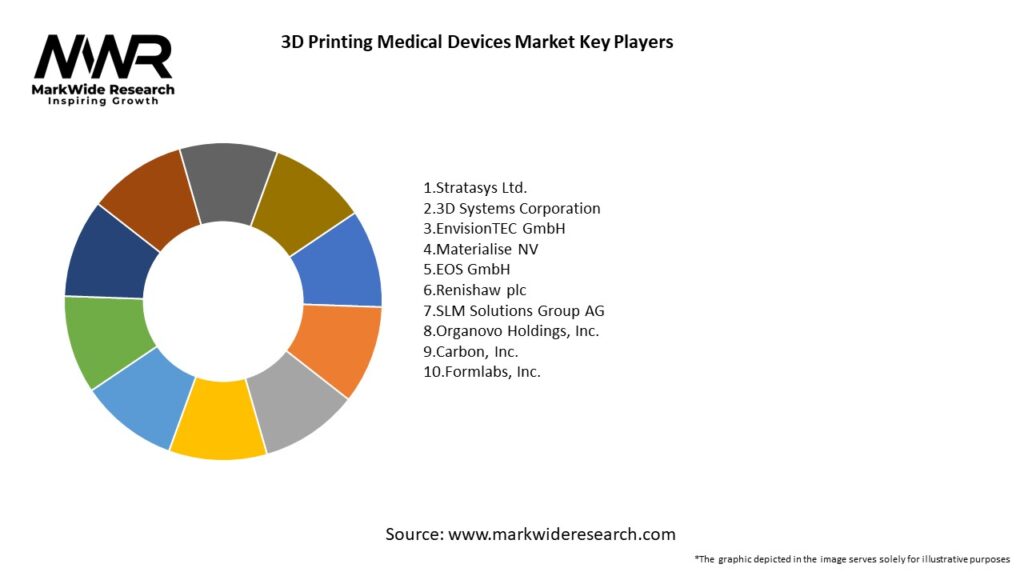

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The following factors are driving the growth of the 3D printing medical devices market:

Market Restraints

Despite the numerous advantages, the 3D printing medical devices market faces certain challenges and restraints, including:

Market Opportunities

The 3D printing medical devices market presents several opportunities for growth and innovation:

Market Dynamics

The 3D printing medical devices market is driven by a combination of technological advancements, increasing demand for personalized healthcare solutions, and the growing prevalence of chronic diseases. The market dynamics are influenced by factors such as regulatory policies, reimbursement coverage, and the availability of suitable materials.

Technological advancements play a crucial role in shaping the market dynamics. Ongoing research and development efforts are focused on enhancing the capabilities of 3D printing technology, improving material properties, and streamlining the manufacturing process. These advancements allow for the production of more complex and functional medical devices, expanding the range of applications and driving market growth.

The demand for personalized healthcare solutions is a significant driver of the market. Patients and healthcare providers are increasingly seeking customized medical devices that offer better treatment outcomes and patient satisfaction. The ability of 3D printing to create patient-specific implants, prosthetics, and surgical instruments addresses this demand, contributing to the market’s growth.

However, regulatory challenges and reimbursement limitations pose restraints to the market expansion. Regulatory authorities are working towards establishing guidelines and standards for the safety and quality of 3D printed medical devices. Harmonizing regulatory policies across different regions is essential to foster market growth and ensure patient safety.

Additionally, the initial investment costs associated with setting up 3D printing infrastructure and the limited availability of biocompatible materials can act as barriers to entry for manufacturers. Addressing these challenges through research and development efforts, collaborations, and strategic partnerships can unlock new opportunities and drive the future growth of the market.

Regional Analysis

The 3D printing medical devices market exhibits regional variations in terms of adoption, technological advancements, and regulatory landscape. The following regions have been prominent in the market:

Competitive Landscape

Leading companies in the 3D Printing Medical Devices Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The 3D printing medical devices market can be segmented based on product type, technology, material, application, and end-user.

Segmenting the market helps in understanding specific market trends, preferences, and demands within each segment. It allows manufacturers to tailor their strategies and offerings to meet the unique requirements of different end-users and applications.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders in the 3D printing medical devices market can benefit in several ways:

SWOT Analysis

A SWOT analysis of the 3D printing medical devices market provides insights into its strengths, weaknesses, opportunities, and threats:

Identifying these internal strengths and weaknesses, as well as external opportunities and threats, helps stakeholders formulate effective strategies and address potential challenges in the market.

Market Key Trends

Several key trends are shaping the 3D printing medical devices market:

Covid-19 Impact

The COVID-19 pandemic has had a significant impact on the healthcare industry, including the 3D printing medical devices market. The pandemic highlighted the importance of rapid manufacturing and supply chain resilience, leading to increased interest in 3D printing for producing medical devices and equipment.

During the crisis, 3D printing played a crucial role in addressing the shortage of critical medical supplies, such as face shields, ventilator components, and nasopharyngeal swabs. The ability of 3D printing to quickly produce these essential items helped in meeting the surge in demand and ensuring healthcare workers’ safety.

The pandemic also accelerated research and development efforts in 3D printing for medical devices. Researchers focused on developing 3D printed solutions for diagnostics, vaccine delivery systems, and personalized protective equipment. The pandemic highlighted the agility and versatility of 3D printing technology, making it a valuable tool in combating healthcare crises.

Additionally, the COVID-19 pandemic underscored the importance of local manufacturing and reducing reliance on global supply chains. 3D printing offers a decentralized production approach, allowing for on-demand manufacturing of medical devices, reducing dependence on overseas suppliers.

Key Industry Developments

The 3D printing medical devices market has witnessed several key industry developments:

Analyst Suggestions

Based on market trends and dynamics, analysts make the following suggestions for industry participants and stakeholders in the 3D printing medical devices market:

Future Outlook

The future of the 3D printing medical devices market looks promising. Technological advancements, increasing demand for personalized healthcare solutions, and the growing prevalence of chronic diseases are expected to drive market growth.

As 3D printing technology continues to evolve, we can anticipate further improvements in material properties, printing speed, and resolution. The development of advanced biocompatible materials specifically designed for medical applications will expand the possibilities for 3D printed medical devices.

Regulatory frameworks are expected to become more defined and standardized, providing clearer guidelines for manufacturers and ensuring patient safety. Reimbursement policies may also evolve to support the adoption of 3D printed medical devices, making them more accessible to healthcare providers and patients.

Conclusion

Moreover, collaborations between healthcare institutions, research organizations, and industry players will drive innovation and foster the development of cutting-edge medical devices. Integration with other technologies such as artificial intelligence and machine learning will enhance the capabilities and efficiency of 3D printing in the medical field.

Overall, the 3D printing medical devices market is poised for significant growth, with expanding applications and advancements in technology driving the future landscape of healthcare.

What is the meaning of 3D Printing Medical Devices?

3D Printing Medical Devices refers to the use of additive manufacturing technologies to create medical devices, including prosthetics, implants, and surgical instruments, tailored to individual patient needs.

Who are the key players in the 3D Printing Medical Devices Market?

Key players in the 3D Printing Medical Devices Market include Stratasys, 3D Systems, Materialise, and Stryker, among others.

What are the main drivers of growth in the 3D Printing Medical Devices Market?

The main drivers of growth in the 3D Printing Medical Devices Market include the increasing demand for personalized medical solutions, advancements in printing technology, and the rising prevalence of chronic diseases requiring innovative treatment options.

What challenges does the 3D Printing Medical Devices Market face?

Challenges in the 3D Printing Medical Devices Market include regulatory hurdles, high initial costs of technology, and the need for skilled professionals to operate advanced printing systems.

What future opportunities exist in the 3D Printing Medical Devices Market?

Future opportunities in the 3D Printing Medical Devices Market include the development of bioprinting technologies, expansion into new therapeutic areas, and collaborations between technology firms and healthcare providers.

What trends are shaping the 3D Printing Medical Devices Market?

Trends shaping the 3D Printing Medical Devices Market include the integration of artificial intelligence in design processes, the use of new biocompatible materials, and the growing focus on sustainability in manufacturing practices.

3D Printing Medical Devices Market

| Segmentation | Details |

|---|---|

| Product | Surgical Guides, Implants, Prosthetics, Others |

| Technology | Stereolithography (SLA), Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the 3D Printing Medical Devices Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at