444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The 3D printing technology has revolutionized various industries, and one of the sectors that has experienced significant advancements is the eyewear market. The 3D printing in eyewear market refers to the utilization of additive manufacturing techniques to produce customized and high-quality eyeglasses, sunglasses, and other eyewear products. This innovative approach offers numerous benefits, including enhanced design flexibility, rapid production, and improved customization options for consumers.

Meaning

3D printing, also known as additive manufacturing, is a process that involves creating three-dimensional objects by adding layer upon layer of material. In the context of eyewear, this technology allows eyewear manufacturers to produce frames, lenses, and other components with precise dimensions and intricate designs. Unlike traditional manufacturing methods, 3D printing enables the production of eyewear that perfectly matches an individual’s facial structure, leading to improved comfort and fit.

Executive Summary

The global 3D printing in eyewear market has witnessed substantial growth in recent years, driven by the increasing demand for personalized eyewear products and the growing adoption of advanced manufacturing technologies. The market is characterized by the presence of both established eyewear brands and emerging players that are leveraging 3D printing technology to offer innovative and unique eyewear solutions. With ongoing advancements in materials, software, and printing technologies, the market is expected to witness further growth in the coming years.

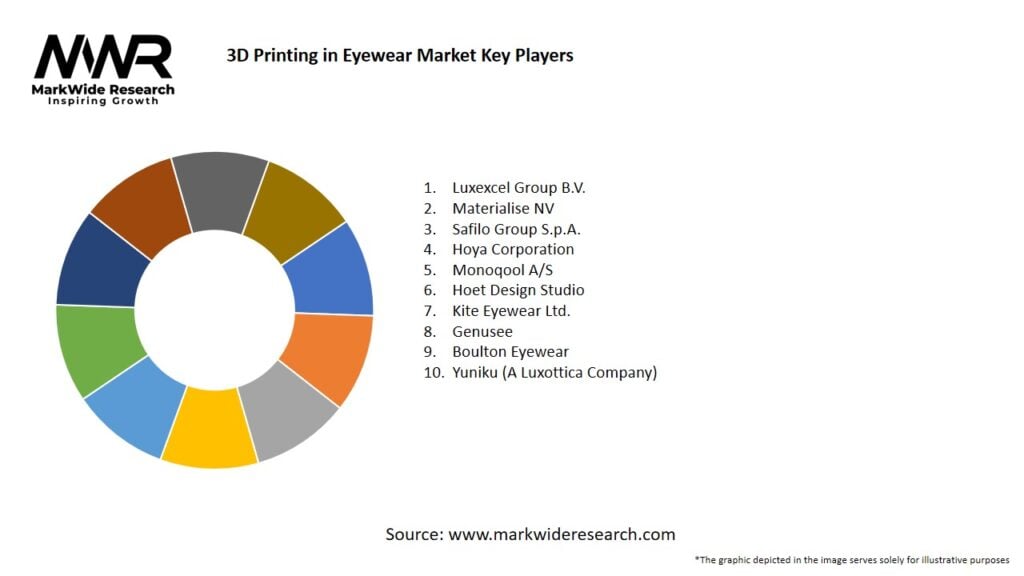

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The 3D printing in eyewear market is driven by several key dynamics. Advancements in 3D printing technology, materials, and software continue to shape the market landscape. The increasing demand for personalized and customized eyewear products is a significant driver, as consumers seek unique designs and optimal fit. Additionally, the push towards sustainable manufacturing practices is fostering the adoption of 3D printing in the eyewear industry. However, challenges such as high initial costs and regulatory considerations need to be addressed for widespread market growth.

Regional Analysis

The adoption of 3D printing in the eyewear market varies across regions. North America and Europe have been at the forefront of embracing this technology, driven by the presence of key market players, technological advancements, and consumer demand for customized products. Asia Pacific is also witnessing rapid growth, fueled by increasing disposable incomes, changing fashion trends, and the presence of emerging economies. Latin America and the Middle East and Africa regions are gradually exploring the potential of 3D printing in eyewear, with growing awareness and investments in additive manufacturing technologies.

Competitive Landscape

Leading Companies in the 3D Printing in Eyewear Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

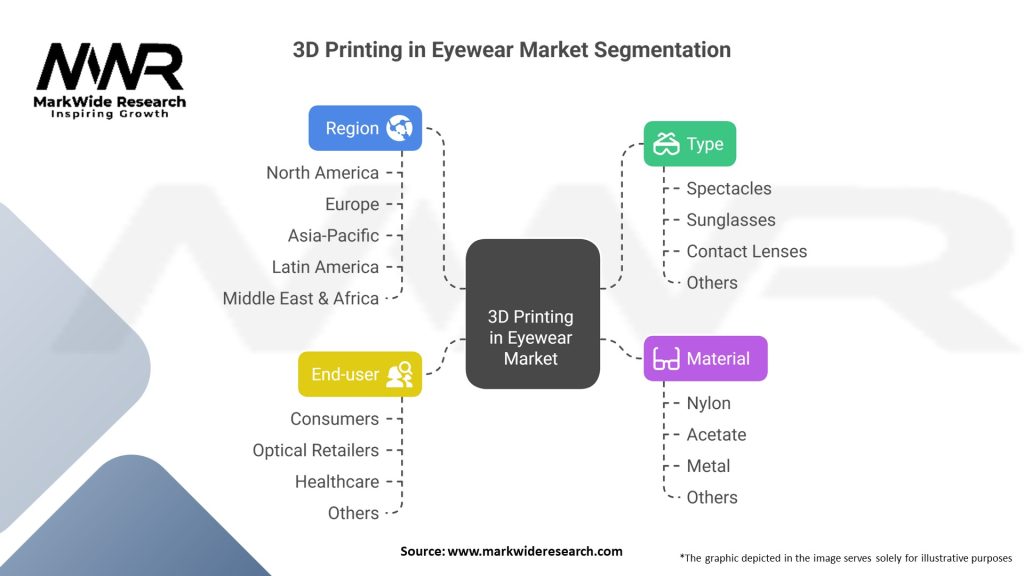

Segmentation

The 3D printing in eyewear market can be segmented based on product type, end-user, and distribution channel. Product types include eyeglasses, sunglasses, contact lenses, and others. End-users can range from individual consumers to opticians, hospitals, and sports organizations. Distribution channels may include retail stores, e-commerce platforms, and specialized eyewear boutiques. Segmentation allows companies to target specific customer segments and tailor their offerings accordingly.

Category-wise Insights

Within the 3D printing in eyewear market, various categories offer unique insights and opportunities. Customized eyeglasses, which account for a significant portion of the market, provide the ability to cater to individual preferences and requirements. Sports eyewear, including specialized goggles and protective gear, offer opportunities for enhanced performance and safety. Additionally, the market for medical and healthcare eyewear holds promise in areas such as vision correction, prosthetics, and personalized lenses.

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders in the 3D printing in eyewear market can enjoy several key benefits. For eyewear manufacturers, adopting 3D printing technology allows for increased production efficiency, reduced costs, and improved customization capabilities. Consumers benefit from eyewear that fits better, is more comfortable, and reflects their personal style. Retailers and distributors can leverage 3D printing in eyewear to offer a wider range of products and attract customers with unique designs. Opticians and healthcare professionals benefit from the ability to provide personalized solutions and improve patient satisfaction. Additionally, technology providers and software developers have opportunities to innovate and collaborate with industry players, expanding their market reach and driving technological advancements. Overall, the adoption of 3D printing in the eyewear market creates a win-win situation for industry participants and stakeholders.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Several key trends are shaping the 3D printing in eyewear market:

Covid-19 Impact

The Covid-19 pandemic has had both positive and negative impacts on the 3D printing in eyewear market. On one hand, the disruption in the global supply chain and manufacturing processes highlighted the benefits of localized production, which 3D printing can facilitate. This has led to increased interest in the technology as a means to achieve supply chain resilience.

On the other hand, the pandemic also posed challenges for the 3D printing in eyewear market. The temporary closure of retail stores and reduced consumer spending affected the overall demand for eyewear products, including those manufactured using 3D printing technology. Additionally, the slowdown in economic activity and uncertainties in the market may have impacted investments and hindered the growth of the market.

However, the pandemic also created opportunities for innovation and adaptation within the industry. Some eyewear manufacturers and 3D printing companies shifted their focus to producing personal protective equipment (PPE), such as face shields and goggles, to meet the increased demand during the crisis. This demonstrated the versatility and agility of 3D printing in responding to changing market needs.

Overall, while the Covid-19 pandemic presented challenges, it also highlighted the potential of 3D printing in the eyewear market to address supply chain vulnerabilities and adapt to evolving circumstances.

Key Industry Developments

The 3D printing in eyewear market has witnessed several key industry developments:

Analyst Suggestions

Based on market trends and observations, analysts make the following suggestions for industry participants in the 3D printing in eyewear market:

Future Outlook

The future outlook for the 3D printing in eyewear market is promising. With ongoing advancements in 3D printing technologies, materials, and design software, the industry is expected to witness further growth. The increasing demand for customized and personalized eyewear products, coupled with the advantages of 3D printing in terms of design flexibility, rapid prototyping, and sustainability, will continue to drive market expansion.

As the technology becomes more accessible and affordable, smaller eyewear companies and start-ups are also expected to enter the market, fostering innovation and competition. Moreover, the integration of technologies like augmented reality and 3D scanning will further enhance the customization process and improve the overall customer experience.

The adoption of 3D printing in eyewear is expected to expand beyond traditional eyeglasses and sunglasses, with opportunities in sports eyewear, medical applications, and specialized lenses. The integration of smart technologies, such as sensors and augmented reality, will further enhance the functionality and appeal of 3D printed eyewear.

Conclusion

In conclusion, the 3D printing in eyewear market is poised for a bright future with opportunities for innovation, customization, and sustainability. Industry participants who adapt to changing customer preferences, invest in technology, and foster strategic collaborations will be well-positioned to capitalize on the growing demand for personalized and technologically advanced eyewear products.

Furthermore, regional markets, particularly in Asia Pacific and emerging economies, present significant growth potential due to increasing disposable incomes, changing fashion trends, and technological advancements. Companies should consider expanding their presence in these regions through strategic partnerships, distribution agreements, and localized manufacturing.

However, challenges such as high initial investment costs, regulatory considerations, and intellectual property protection need to be addressed to ensure sustainable growth. Continued efforts in research and development, advancements in materials, and the development of user-friendly customization platforms will play a crucial role in driving market expansion.

What is 3D Printing in Eyewear?

3D Printing in Eyewear refers to the use of additive manufacturing technologies to create customized eyewear products, including frames and lenses. This process allows for greater design flexibility, personalization, and rapid prototyping compared to traditional manufacturing methods.

What are the key companies in the 3D Printing in Eyewear market?

Key companies in the 3D Printing in Eyewear market include Luxottica, Essilor, and Mykita, which are known for their innovative approaches to integrating 3D printing technology into eyewear production, among others.

What are the growth factors driving the 3D Printing in Eyewear market?

The growth of the 3D Printing in Eyewear market is driven by increasing consumer demand for personalized products, advancements in printing technology, and the ability to reduce waste in manufacturing processes. Additionally, the rise of online eyewear retailers is contributing to this trend.

What challenges does the 3D Printing in Eyewear market face?

Challenges in the 3D Printing in Eyewear market include the high initial costs of advanced printing equipment, regulatory hurdles regarding material safety, and the need for skilled labor to operate and maintain the technology. These factors can hinder widespread adoption.

What opportunities exist in the 3D Printing in Eyewear market?

Opportunities in the 3D Printing in Eyewear market include the potential for creating sustainable eyewear solutions using eco-friendly materials and the ability to cater to niche markets with unique design requirements. Additionally, collaborations between tech companies and eyewear brands can foster innovation.

What trends are shaping the 3D Printing in Eyewear market?

Trends in the 3D Printing in Eyewear market include the increasing use of bio-based materials, the rise of on-demand production to reduce inventory costs, and the integration of augmented reality for virtual try-ons. These innovations are enhancing the consumer experience and driving market growth.

3D Printing in Eyewear Market Segmentation Details:

| Segmentation | Details |

|---|---|

| Type | Spectacles, Sunglasses, Contact Lenses, Others |

| Material | Nylon, Acetate, Metal, Others |

| End-user | Consumers, Optical Retailers, Healthcare, Others |

| Region | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the 3D Printing in Eyewear Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at