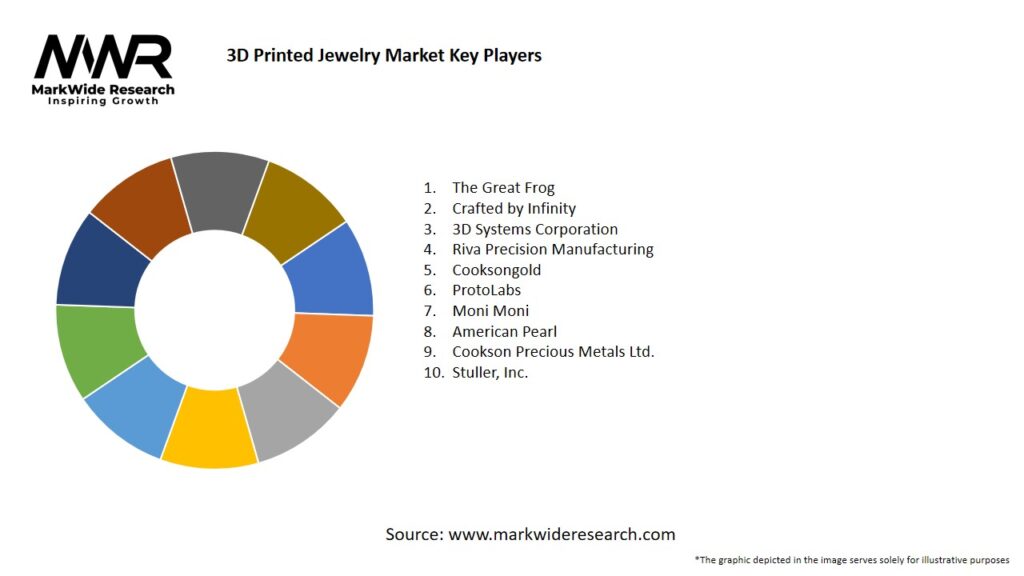

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

-

Material Innovation: Growth in biocompatible resins and gold/silver phosphor bronze powders tailored for jewelry printing is expanding application scope.

-

Desktop vs. Industrial Printers: While enterprise-grade metal printers capture high-volume production, desktop resin/SLA printers enable small designers to enter the market with minimal capital.

-

Customization Platforms: Marketplaces offering user‑friendly customization (e.g., ring size, pattern selection) are driving consumer adoption.

-

Sustainability Focus: Additive manufacturing’s minimal waste and lower energy consumption appeal to eco‑conscious consumers and brands.

-

Skill Shift: Demand for CAD expertise among jewelry designers is rising, shifting education and hiring toward digital competencies.

Market Drivers

-

Rising Demand for Personalization: Consumers increasingly seek unique, bespoke jewelry that reflects personal stories, driving custom 3D-printed offerings.

-

Technological Advancements: Improvements in printer resolution, multi‑material capabilities, and post‑processing technologies enhance final product quality.

-

Cost Efficiency at Low Volumes: Traditional casting demands high tooling costs; 3D printing eliminates molds, making small runs economical.

-

Shorter Time‑to‑Market: Rapid prototyping allows designers to test and launch new collections in weeks rather than months.

-

E‑commerce Growth: Online platforms simplify the ordering process for personalized jewelry, increasing accessibility.

Market Restraints

-

High Equipment Costs: Premium metal additive manufacturing systems remain expensive, limiting access for small‑scale jewelers.

-

Material Certification: Approval processes for precious-metal powders in jewelry applications can be lengthy and costly.

-

Post‑Processing Needs: Printed parts require polishing, plating, or casting for final finish, adding complexity.

-

Design Learning Curve: Mastery of 3D CAD software and printing parameters requires investment in training.

-

Consumer Perceptions: Some consumers remain skeptical of additive manufacturing’s quality compared to traditional handcrafted jewelry.

Market Opportunities

-

Emerging Market Penetration: Growth potential in Asia‑Pacific and Latin America as awareness and disposable incomes rise.

-

Hybrid Manufacturing Models: Combining printed patterns with traditional metal casting (lost‑wax method) can blend efficiencies and finish quality.

-

Advanced Alloys Development: Research into printable gold‑platinum alloys can open high‑end jewelry segments.

-

Collaborations with Fashion Brands: Partnerships between tech firms and established luxury houses can drive innovation and prestige.

-

Localized On‑Demand Production: Setting up micro‑factories near urban centers to reduce lead times and shipping costs.

Market Dynamics

-

Supply Side: Steady improvements in additive equipment throughput, material costs, and software usability. Emergence of co‑development partnerships between printer manufacturers and material suppliers.

-

Demand Side: Expanding base of digitally native consumers accustomed to online customization. Growing B2B interest from jewelry OEMs seeking to streamline prototypes and small-lot production.

-

Economic Factors: Fluctuating precious metal prices can influence adoption rates for direct metal printing versus resin prototyping. Economic growth in emerging regions correlates with rising luxury goods consumption.

Regional Analysis

-

North America: Leading in technology adoption, with a robust ecosystem of printer manufacturers, material suppliers, and design agencies. High consumer spending on personalized luxury goods.

-

Europe: Strong presence of luxury brands experimenting with high‑end 3D printed collections. Regulatory support for advanced manufacturing and sustainable practices.

-

Asia‑Pacific: Fastest-growing region, driven by China’s domestic jewelry market expansion and growing designer communities in India, Japan, and South Korea. Emergence of local material suppliers reduces costs.

-

Latin America & Middle East: Early stages but growing interest among boutique designers and luxury consumers. Potential for regional production to serve local markets.

Competitive Landscape

Leading Companies in the 3D Printed Jewelry Market

- The Great Frog

- Crafted by Infinity

- 3D Systems Corporation

- Riva Precision Manufacturing

- Cooksongold

- ProtoLabs

- Moni Moni

- American Pearl

- Cookson Precious Metals Ltd.

- Stuller, Inc.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

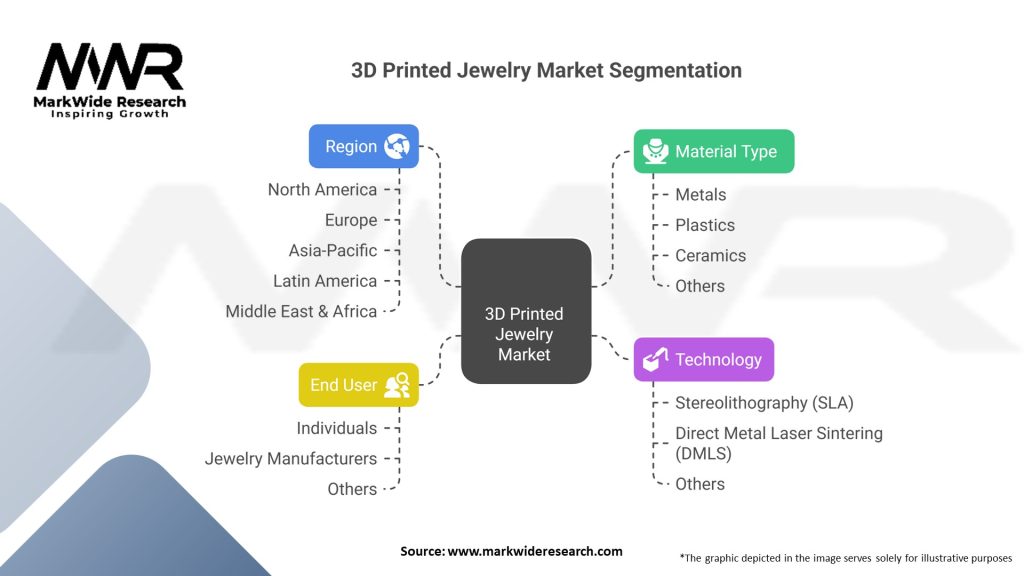

Segmentation

-

By Technology:

-

Resin/SLA & DLP Printing (prototyping, limited final‑use)

-

Metal Powder Bed Fusion (direct final‑use in gold, silver, stainless steel)

-

Binder Jetting (sand casting patterns, lower resolution)

-

-

By Material:

-

Photopolymer Resins (wax‑like casting patterns)

-

Precious Metal Powders (gold, silver, platinum)

-

Base Metal Powders (bronze, brass, stainless steel)

-

-

By Application:

-

Bespoke/Custom Jewelry

-

Mass‑Customization (online retailers offering parameter‑driven designs)

-

High‑End/Luxury Collections

-

-

By End User:

-

Jewelry Designers & Artisans

-

Jewelry OEMs & Brands

-

Consumers (via direct e‑commerce)

-

Category-wise Insights

-

Resin Prototyping: Widely used by designers for rapid concept validation and casting pattern production; lower material cost but requires downstream casting.

-

Direct Metal Printing: Enables true one‑off or small‑lot manufacturing in final precious metal; higher material and equipment costs but eliminates casting steps.

-

Hybrid Models: Use printed resin patterns for traditional lost‑wax casting, balancing costs and finish quality.

Key Benefits for Industry Participants and Stakeholders

-

Reduced Time & Costs: Accelerated product development cycles and elimination of tooling.

-

Enhanced Creativity: Freedom to experiment with forms and structures not possible with stock findings or mold‑based methods.

-

Sustainability: Lower material waste and energy usage compared to conventional metalworking.

-

Market Differentiation: Ability to offer truly personalized pieces, driving consumer engagement and loyalty.

-

Scalable Customization: Economical one‑off pieces and small series production without tooling overhead.

SWOT Analysis

-

Strengths:

-

High design flexibility

-

Reduced lead times

-

Lower inventory requirements

-

-

Weaknesses:

-

Equipment and material costs

-

Need for skilled CAD/design talent

-

-

Opportunities:

-

Growth in emerging markets

-

Integration with AR‑powered virtual try‑on

-

Expanded material portfolio (advanced alloys)

-

-

Threats:

-

Regulatory hurdles for precious‑metal printing

-

IP concerns over digital file sharing

-

Competition from mass‑manufactured lower‑cost alternatives

-

Market Key Trends

-

AI‑Driven Generative Design: Automated creation of optimized jewelry geometries based on performance or aesthetic parameters.

-

Virtual Try‑On & AR Integration: Online platforms enabling consumers to visualize custom pieces on themselves before purchase.

-

Multi‑Material Printing: Combining metals and polymers or gemstones in a single build process.

-

Blockchain for Provenance: Tracking digital design files and material sources to certify authenticity and ethical sourcing.

-

Localized Micro‑Factories: Urban production labs offering same‑day customization and pickup.

Covid-19 Impact

-

Accelerated Digital Adoption: Remote design collaboration and e‑commerce soared as studios shut physical outlets.

-

Supply Chain Resilience: On‑demand production reduced reliance on lengthy import/export cycles.

-

Shift in Consumer Behavior: Increased desire for meaningful, personalized purchases spurred custom jewelry demand.

-

Health & Safety Concerns: Touch‑free ordering, virtual appointments, and sanitized production workflows became standard.

Key Industry Developments

-

EOS’s Precious Metal Solutions: Launch of high‑resolution metal PBF systems tailored for jewelry.

-

Carbon & Custom Jewelry: Partnering with jewelry houses to introduce high‑throughput resin printing for patterns.

-

Autodesk’s Jewelry Lab: AI‑powered generative design tools integrated in Fusion 360 for direct jewelry workflows.

-

Jewelry CAD Dream Teams: Collaborations between design houses and tech startups to co‑develop next‑gen collections.

Analyst Suggestions

-

Invest in Material R&D: Develop new printable alloys with optimized grain structures for superior finish and durability.

-

Build Digital Ecosystems: Integrate 3D design, AR visualization, and direct ordering into seamless e‑commerce experiences.

-

Expand Training Programs: Upskill traditional jewelers in CAD and additive manufacturing to bridge the talent gap.

-

Pursue Standards & Certification: Collaborate with industry bodies to establish material and process standards, boosting consumer confidence.

-

Explore Hybrid Business Models: Combine online customization with in‑store showrooms for a blended digital‑physical sales channel.

Future Outlook

The 3D printed jewelry market is set to grow robustly as technologies mature and costs decline. Key forecast drivers include:

-

Mainstreaming of Precious Metal Printing: Wider adoption by established luxury brands as equipment becomes more accessible.

-

Democratization of Design: Web‑based customization tools enabling everyday consumers to become co‑designers.

-

Sustainability Mandates: Brands under pressure to reduce waste and carbon footprints will increasingly turn to additive manufacturing.

-

Consolidation & Partnerships: Increased M&A activity as printer manufacturers, material suppliers, and jewelry houses align their offerings.

-

Innovation in Finishing Techniques: Development of automated post‑processing solutions to polish, plating, and gemstone setting for printed pieces.

Conclusion

3D printed jewelry is revolutionizing how we design, produce, and consume personal adornments. By empowering unprecedented creative freedom, enabling true personalization, and reducing environmental impact, additive manufacturing is redefining industry norms. Stakeholders—from solo artisans to global luxury brands—stand to benefit by embracing integrated digital workflows, investing in advanced materials, and forging new partnerships across the technology and fashion ecosystems. As the market evolves, those who master the intersection of design, data, and digital fabrication will lead the next wave of innovation in the jewelry industry.