444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The 3D medical implant market represents a revolutionary frontier in healthcare, offering advanced solutions for complex surgical procedures and patient-specific treatments. Leveraging additive manufacturing technologies, 3D medical implants are customized to fit individual patient anatomies, enhancing surgical outcomes and patient satisfaction. With applications ranging from orthopedics to craniofacial reconstruction, the 3D medical implant market is poised for exponential growth, driven by advancements in materials science, digital imaging, and surgical techniques.

Meaning

3D medical implants are precisely engineered implants manufactured using additive manufacturing processes, also known as 3D printing. These implants are tailored to match the unique anatomical characteristics of individual patients, offering superior fit, functionality, and biocompatibility compared to traditional off-the-shelf implants. By leveraging advanced imaging techniques such as CT scans and MRI, medical professionals can design and fabricate 3D implants that optimize patient outcomes and minimize surgical complications.

Executive Summary

The 3D medical implant market is experiencing rapid growth fueled by increasing demand for personalized healthcare solutions and advancements in additive manufacturing technologies. Key drivers include the growing prevalence of chronic diseases, rising geriatric population, and expanding applications in orthopedics, dental, and reconstructive surgery. However, challenges such as regulatory hurdles, high production costs, and limited reimbursement options pose potential constraints. To capitalize on market opportunities and overcome challenges, stakeholders must prioritize innovation, collaboration, and regulatory compliance.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

The 3D medical implant market is characterized by several key insights:

Market Drivers

Several factors are driving the growth of the 3D medical implant market:

Market Restraints

Despite the market’s growth potential, several challenges and constraints exist:

Market Opportunities

Despite these challenges, the 3D medical implant market presents significant growth opportunities:

Market Dynamics

The 3D medical implant market operates in a dynamic environment influenced by technological advancements, regulatory developments, market trends, and competitive dynamics. Understanding these dynamics is essential for stakeholders to navigate market complexities, capitalize on opportunities, and mitigate risks.

Regional Analysis

The 3D medical implant market exhibits regional variations in market dynamics, regulatory frameworks, healthcare infrastructure, and patient demographics. While developed regions such as North America and Europe dominate market share, emerging markets in Asia-Pacific, Latin America, and the Middle East present significant growth opportunities due to increasing healthcare expenditure and adoption of advanced medical technologies.

Competitive Landscape

Leading Companies in 3D Medical Implant Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

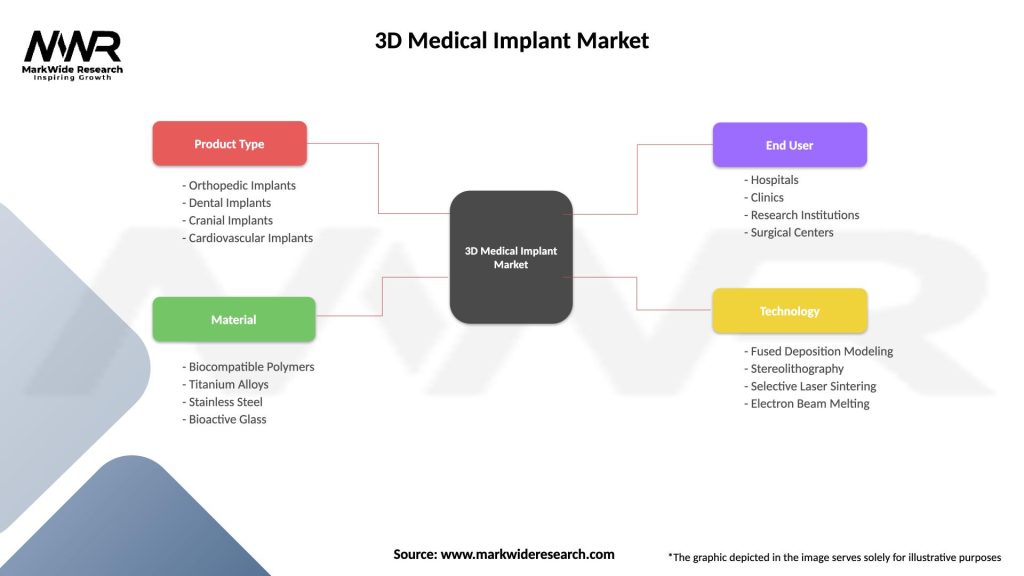

Segmentation

The 3D medical implant market can be segmented based on various factors, including implant type, material, application, end-user, and geography. By understanding these segments, market participants can tailor their product offerings and marketing strategies to target specific customer needs and preferences.

Category-wise Insights

3D medical implants find applications across various medical specialties, including orthopedics, maxillofacial surgery, neurosurgery, and otolaryngology. From patient-specific joint replacements to custom cranial implants, 3D medical implants offer innovative solutions to address a wide range of clinical challenges and improve patient outcomes.

Key Benefits for Industry Participants and Stakeholders

The 3D medical implant market offers several benefits for industry participants and stakeholders, including:

SWOT Analysis

Strengths:

Customization and Precision: 3D printing enables patient-specific implants, improving fit and reducing surgery time.

Innovation and Technological Advancements: Continuous R&D in materials like titanium and biocompatible polymers enhances implant durability.

Reduced Production Time and Cost: Compared to traditional manufacturing, 3D printing lowers waste and speeds up prototyping.

Improved Clinical Outcomes: Enhanced biocompatibility and design flexibility lead to faster patient recovery and reduced infection risks.

Weaknesses:

High Initial Investment: Advanced 3D printers and regulatory certifications involve significant costs.

Limited Skilled Workforce: Shortage of professionals trained in medical 3D printing and digital design.

Regulatory Challenges: Complex approval processes for customized implants slow market entry.

Opportunities:

Growing Demand for Personalized Healthcare: Increasing acceptance of patient-specific implants in orthopedics and dental sectors.

Expansion in Emerging Markets: Rising healthcare infrastructure and spending in developing regions.

Material Innovation: Development of bioresorbable and hybrid materials for advanced implants.

Threats:

Stringent Regulatory Policies: Constantly evolving medical device regulations can delay commercialization.

Cybersecurity Risks: Vulnerability of digital design files to data breaches.

Market Competition: Rapid technological evolution may render existing solutions obsolete.

Market Key Trends

Key trends in the 3D medical implant market include:

Covid-19 Impact

The COVID-19 pandemic has had a significant impact on the 3D medical implant market, disrupting supply chains, delaying elective surgeries, and shifting healthcare priorities. However, as healthcare systems adapt to the new normal and surgical volumes rebound, the market is expected to recover and continue its growth trajectory driven by the increasing demand for personalized healthcare solutions and advancements in additive manufacturing technologies.

Key Industry Developments

Recent industry developments include advancements in implant design and fabrication techniques, regulatory approvals for new implant designs and materials, and strategic collaborations among industry stakeholders to drive innovation and market expansion.

Analyst Suggestions

Analysts suggest that industry participants focus on innovation, collaboration, and regulatory compliance to capitalize on market opportunities and overcome challenges. Emphasizing the clinical benefits of 3D medical implants, fostering partnerships with healthcare providers, and investing in research and development are essential strategies for sustainable growth in the dynamic 3D medical implant market.

Future Outlook

The future outlook for the 3D medical implant market is optimistic, with increasing demand for personalized healthcare solutions, advancements in additive manufacturing technologies, and expanding applications in orthopedics, dental, and reconstructive surgery expected to drive market growth. However, challenges such as regulatory hurdles, cost considerations, and reimbursement limitations may require industry stakeholders to adopt innovative strategies to navigate market complexities and capitalize on emerging opportunities.

Conclusion

The 3D medical implant market represents a transformative shift in healthcare, offering personalized treatment solutions tailored to individual patient anatomies. Despite challenges such as regulatory hurdles, cost considerations, and reimbursement limitations, the market presents significant growth opportunities driven by increasing demand for personalized healthcare solutions, advancements in additive manufacturing technologies, and expanding applications in orthopedics, dental, and reconstructive surgery. By prioritizing innovation, collaboration, and regulatory compliance, industry participants can capitalize on market opportunities, overcome challenges, and contribute to the advancement of personalized medicine and patient care.

What is 3D Medical Implant?

3D Medical Implants are advanced medical devices created using three-dimensional printing technology, allowing for customized shapes and sizes tailored to individual patient needs. These implants are used in various applications, including orthopedic, dental, and cranial surgeries.

What are the key players in the 3D Medical Implant Market?

Key players in the 3D Medical Implant Market include companies like Stratasys, Materialise, and Stryker, which are known for their innovative approaches to additive manufacturing in healthcare. These companies focus on developing personalized implants and improving surgical outcomes, among others.

What are the growth factors driving the 3D Medical Implant Market?

The growth of the 3D Medical Implant Market is driven by factors such as the increasing demand for personalized medical solutions, advancements in 3D printing technology, and the rising prevalence of chronic diseases requiring surgical interventions. Additionally, the growing focus on minimally invasive procedures contributes to market expansion.

What challenges does the 3D Medical Implant Market face?

The 3D Medical Implant Market faces challenges such as regulatory hurdles, high manufacturing costs, and the need for extensive clinical validation. These factors can hinder the widespread adoption of 3D printed implants in clinical settings.

What opportunities exist in the 3D Medical Implant Market?

Opportunities in the 3D Medical Implant Market include the potential for innovations in biocompatible materials and the expansion of applications in regenerative medicine. Furthermore, collaborations between technology companies and healthcare providers can enhance product development and market reach.

What trends are shaping the 3D Medical Implant Market?

Trends shaping the 3D Medical Implant Market include the increasing integration of artificial intelligence in design processes, the development of patient-specific implants, and the growing emphasis on sustainability in manufacturing practices. These trends are expected to enhance the efficiency and effectiveness of medical implants.

3D Medical Implant Market

| Segmentation Details | Description |

|---|---|

| Product Type | Orthopedic Implants, Dental Implants, Cranial Implants, Cardiovascular Implants |

| Material | Biocompatible Polymers, Titanium Alloys, Stainless Steel, Bioactive Glass |

| End User | Hospitals, Clinics, Research Institutions, Surgical Centers |

| Technology | Fused Deposition Modeling, Stereolithography, Selective Laser Sintering, Electron Beam Melting |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in 3D Medical Implant Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at